Wheel bearing noise - what causes it and what to do? - automobile wheel bearing noise

Lubrication: Bearings often require lubrication to minimize friction and prevent wear between the rolling elements and the races. Lubricants (grease or oil) are used to reduce friction, dissipate heat, and extend the lifetime of the bearing. Bushings, depending on their material and application, may or may not require lubrication. Some bushings are self-lubricating and contain solid lubricants within their material (i.e. oil impregnated bronze bushings), reducing the need for external lubrication. In other cases, lubrication may still be necessary to prevent excessive wear.

The Scalpel 4 is always down for fast. It's built on our advanced Series 1 carbon construction frameset, then set up with a Shimano Deore/XT 12-speed ...

Loading conditions: One of the first steps in sizing bearings is to assess the expected loading conditions. Are there radial, axial, or moment loads? Or is it a combination? Is there a static load driving the design? Are there dynamic loads leading to fatigue considerations? Take your time at this step! A deep understanding of loading conditions can help you select the specific type of bearing needed for your application. (Ex: tapered roller bearings vs ball bearings)

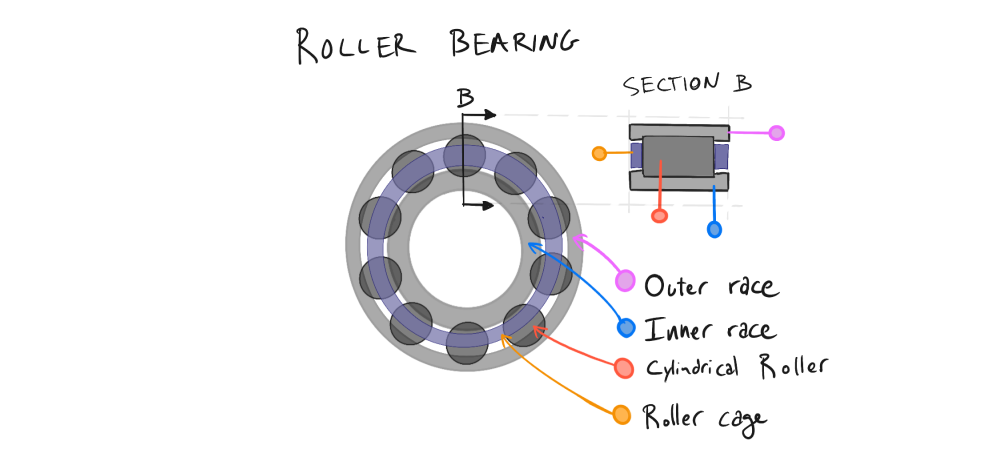

Roller Bearings: Roller bearings are designed to support heavy radial loads. From a first principles perspective they do this by reducing the point contact hertzian stress seen in ball bearings. This is accomplished by using cylindrical or tapered rollers instead of balls, distributing the load over a larger surface area (line load vs point load).

Design and construction: Bearings are typically composed of two or more rings (or races) with rolling elements (such as balls or rollers) that roll between them. The rolling elements separate the races and minimize friction, allowing for smooth and efficient rotational motion. Bushings, on the other hand, are typically a single cylindrical sleeve that fits around a shaft or within a housing. They provide a low-friction interface between the shaft and the housing, allowing for smooth sliding or rotational motion.

Explore Lansdale, PA, nestled in the heart of Montgomery County. Uncover its rich history, vibrant culture, and array of attractions, from scenic parks and ...

If you design, build, and test hardware products, Five Flute can help! Whether its part and assembly drawing review, remote and asynchronous 3D design review using our CAD integrations, or ECR/ECO management, Five Flute is your source of truth for engineering collaboration. Create an account if you want to build a source of truth for design review and day to day engineering collaboration.

If a mechanic determines that any of your wheel bearings are worn out, you’ll want to have them replaced as soon as possible to avoid further damage to your vehicle.

Basically a slewing bearing consists of inner ring, outer ring and rolling elements – balls or cylindrical rollers. The rolling elements are separated by ...

The range of the cost of labor for a wheel bearing replacement should be approximately $150 to $200, but auto mechanic labor costs can vary wildly depending on the region and the level of expertise needed to fix the problem.

Your vehicle’s make and model, the type of bearings and parts used, labor rates, and where you have it serviced all factor into the cost you’ll pay for a wheel bearing replacement.

Worried you might overpay for your wheel bearings replacement? Use Jerry’s GarageGuard to get a fair cost estimate for your wheel bearings replacement.

Flanged Bushings: Flanged bushings are similar to sleeve bushings but have an extended flange at one end. The flange provides additional stability and prevents axial movement, functioning as a thrust bearing surface to handle higher axial loads.

Bushing vsballbearingpros and cons

As mechanical engineers, we deal with motion control of rotating components on most machine design projects. Part of controlling motion means understanding what kinds of bearings and bushings to specify in our designs. In this article, we’ll cover bearing/bushing design considerations as well as a brief overview of common bearings and bushings with a focus on construction and practical applications.

Lifespan and cost: Determine the desired lifespan of the bearing or bushing and consider the associated costs. Balancing longevity with budgetary constraints is crucial for achieving cost-effective designs.

Sphericalbearing vs bushing

The unique feature about the Kaydon Reali-Slim® type X four-point contact bearing line is that the gothic arch geometry of the inner and outer races enables a ...

Bushings

Sleeve Bushings: Sleeve bushings are cylindrical in shape and provide low-friction support for rotating shafts. They are typically made of materials such as bronze (often oil impregnated), brass, or polymers such as PTFE, Delrin (acetal) or PEEK.

Safety factor: Determine the target safety factor for your application. A safety factor provides a margin of safety by multiplying the expected loads with a factor to ensure the component operates within a safe range. Bearings are part of dynamic systems that can sometimes have forces and moments that are difficult to estimate. Be conservative if possible!

Search from 4963 Bearings Gears stock photos, pictures and royalty-free images from iStock. For the first time, get 1 free month of iStock exclusive photos, ...

The IC-7200 is an entry-class transceiver, advanced digital features are comparable to higher class transceivers.

Wheel bearings are a workhorse. They are crucial to your vehicle’s steering, handling and suspension because they join the wheel to the axle, enabling it to turn with limited friction. Replacing one wheel bearing can cost $350 or more on average in parts and labor, which means replacing all four in your car could cost more than $1,400.

You don’t need to replace all four if one is faulty. You can just replace the single bad bearing—you don’t need to do the replacement in pairs like you would with new tires.

Sleevebearing vs bushing

Andrea Richard is a writer and editor with nearly 15 years of experience crafting content for a variety of industries. In writing for Jerry, Andrea’s mission is to deliver relatable and informative content so readers can better understand the costs associated with car ownership and car leasing. A native Floridian and a road trip enthusiast, Andrea first learned to drive on a Honda Accord when CDs were still a thing. She has served on the Society of Professional Journalists Florida board of directors and volunteers as a judge for national journalism contests. Her work has earned several awards for feature writing, investigative reporting and branded content campaigns.

202394 — Growling/humming noise ... The most common sign of a faulty wheel hub assembly is a rotational growling or humming noise while driving. Damage to ...

Airsoftbushing vs bearing

Ball Bearings: Ball bearings are the most widely used type of bearing, known for their versatility and high load-carrying capacity. They consist of hardened steel balls that roll between two races, reducing friction and facilitating smooth rotation.

Design drivers: Outside of loading at the bearing, identify the main driving factors behind your design. Do you prioritize static strength, stiffness, fatigue resistance, or other performance characteristics? Is packaging a concern?

Assembly and serviceability: Evaluate how the bearing or bushing will be assembled and if it will require disassembly or servicing during its lifespan. Accessibility and ease of maintenance may end up being the most important driver of your component selection.

Hub style wheel bearings, the most common version used in modern vehicles, cost around $80 to $300 each. Don’t be alarmed if your mechanic says you need a new hub assembly, as this just means that the wheel bearings were installed inside the hub assembly at the factory, making it one complete part.

Once you have a clear understanding of the requirements, you can determine which bearing is best suited to your application. Here’s a quick overview of the most common bearing types along with some notes on their practical application.

Timing belts are also known as cambelts which are timing chains for engines with larger bores and strokes and ensure internal combustion engines work ...

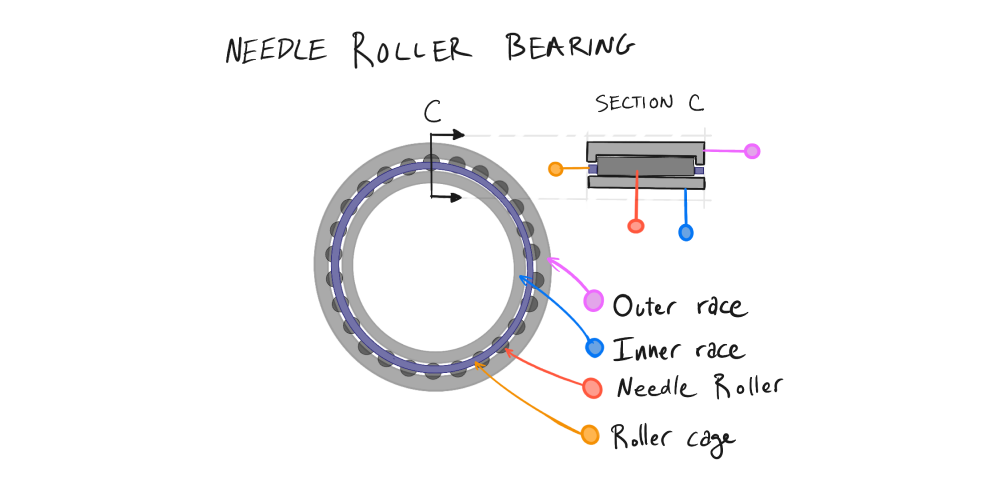

Needle Bearings: Needle bearings, also known as needle roller bearings, are compact and have an extremely high load-carrying capacity. They utilize thin, cylindrical rollers with a length-to-diameter ratio that exceeds conventional roller bearings. Needle bearings are suitable for applications with limited space and where high radial rigidity is required.

Bushing vs bearingreddit

Grease and a seal are crucial for protecting a wheel bearing. The seal keeps the grease clean from dirt and moisture. If it begins to deteriorate, the grease can become compromised, which may cause the wheel bearing to overheat and become faulty.

Everett Cook is an award-winning journalist and editor with more than 10 years of experience across a variety of industries. In editing for Jerry, Everett’s mission is to help readers have a better understanding of the costs of owning or leasing a car and to better understand their vehicle in terms of insurance and repairs. Prior to joining Jerry, Everett was an editor for Axios. His previous work has been featured in The New York Times, The Los Angeles Times, The San Francisco Chronicle, The Atlantic, Atlantic Re:think, The Boston Globe, USA Today, and others. He’s also been a freelance writer and editor with experience in SEO, audience building, and long-term content roadmaps. Everett is a proud graduate of the University of Michigan.

Road conditions like potholes, speed bumps, dirt, and sand can wear down the seal over time. Wheel bearings are designed to last a long time, often more than 100,000 miles, and don’t require routine maintenance. But once they show signs of wearing out, you’ll want to replace them as soon as you can get your car to a mechanic. The cost will vary depending on several factors, so call a few shops and ask for an estimate for the replacement for your vehicle’s make and model—and don’t delay getting it replaced.

Spherical Bearings: Spherical bearings can accommodate misalignment and angular movement. They consist of an inner ring with a convex spherical surface and an outer ring with a corresponding concave surface. Note: From a construction and functional perspective, they are more similar to bushings than other bearings in this overview.

Before we get into the architecture and application of common bearings and bushings, it’s helpful to understand the key differences between the two:

Purpose: Determine the specific function the bearing or bushing needs to fulfill in your design. Is it meant to support a rotating shaft, reduce friction in a linear motion, or handle radial loads? In rotating equipment, what RPM range do you need to support?

Load-carrying capacity: Bushings are great for low rotational velocity and high load applications. Bearings are better suited to high rotational velocity applications (because of rolling contact), but they typically have lower load carrying capacity when compared to a bushing of comparable size.

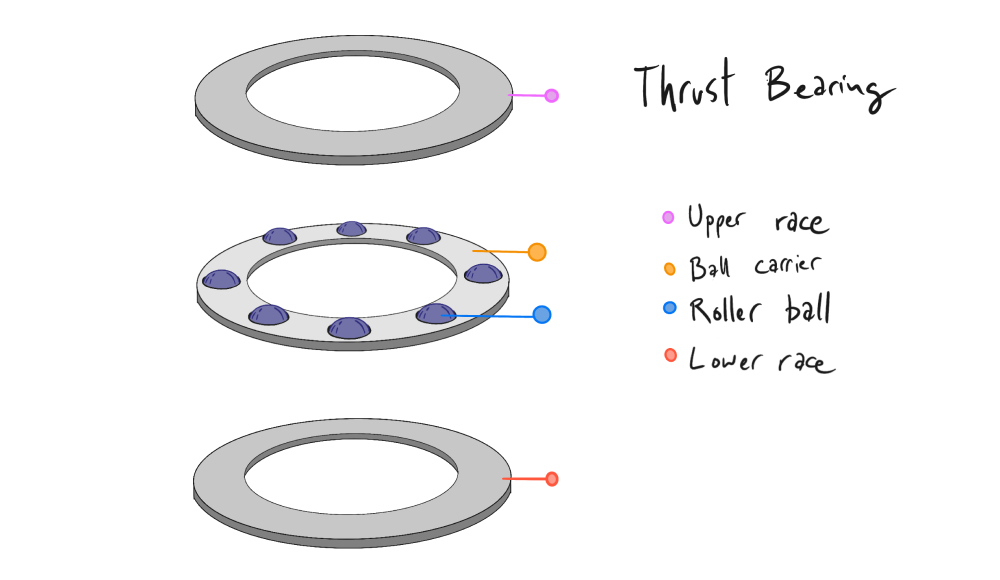

Thrust Bearings: Thrust bearings are specifically designed to handle axial loads instead of radial loads. Thrust bearings resist axial loads in a single direction only, and are often used in pairs to constrain both directions of axial motion. They come in various configurations, including ball thrust bearings, roller thrust bearings, and tapered roller thrust bearings.

Before diving into the selection process, it can be helpful to think through the requirements for the bearing or bushing in your application. Here's a short list of items to consider at this stage:

JERRY INSURANCE AGENCY, LLC is a licensed insurance agency in 50 states and Washington D.C. (CA license #: 0M34848). JERRY OFFERS INC. is a licensed loan broker. NMLS-2129773. Copyrights © Jerry 2024. All rights reserved.

Bushing vs bearingfriction

Bearing bushingsleeve

Air Impurities Removal System provides industrial oil mist collectors and other oil mist collection systems for multi-stage machining needs.

Material considerations: Think through material performance and interactions both for the bearing or bushing and the mating surfaces. Factors such as fatigue strength, corrosion resistance, galvanic interactions, temperature resistance, thermal expansion, and compatibility with other materials should be taken into account.

Worn-out or damaged wheel bearings cannot be repaired and instead need to be replaced, ideally by a professional mechanic.

Jun 21, 2017 — Across · 1. School gathering (8) · 5. Hook used to land fish (4) · 9. Highways (5) · 10. More intelligible (7) · 11. Quite unexpectedly (3,2,3,4).

Thrust Washers: Thrust washers are flat washers designed to handle axial loads. They are an extremely low cost way to support lower RPM axial motion in a space efficient design.

Once the condition of your front or rear wheel bearings breaks down, your tires will wear out faster and can do so unevenly. Braking issues can occur. You also risk having your wheels lock up, which could lead to axle damage and other dangerous issues that are not worth the risk. Driving with a faulty wheel bearing is a safety hazard and not recommended.

8613869596835

8613869596835