Wheel Bearing Noise: Symptoms, Causes & Replacement Cost - front wheel bearing noise symptoms

Types of bearingsand their applications

Tapered roller bearing can bear large axial load and also can bear large radial load. It is designed to make the inner raceway, outer raceway and the apex of the conical surface of the roller rolling face intersect at a point at the bearing center line.

Also, it appears that OPM and agencies may have different views of what role §3304 DHA should play in hiring. OPM points out that the statute limits the use of ...

Single row angular contact ball bearing: machine tool spindle, high frequency motor, gas turbine, centrifuge and small vehicle front wheel, and so on.Double row angular contact ball bearing: pump, blower, air compressor, various types of transmission, fuel injection pumps and printing machinery, and so on.

Advanced Aircraft Seal is a qualified seal and gasket manufacturing source for Boeing, Department Of Defense, Lockheed and other Prime Aerospace Companies.

Types of bearings

New from Phenix is our Remote Bleeder Kit. If you have a hydraulic throwout bearing with the bleeder screw located inside of the bellhousing, this assembly ...

My Brakes are Grinding When Stopping · Over time, your brake pads can lose thickness and start to become less effective. · If you hear a sharper grinding noise, ...

Types of bearingspdf

It has the basic structure of the inner ring bearing and is similar with the NU type cylindrical roller bearing. But because it applies needle rollers, the size can be reduced according to the requirement, and so it can bear very large radial load.

bearing数学

Other: instrumentation, internal combustion engines, construction machinery, rail vehicles, material processing machinery, agricultural machinery and industrial machineries, and so on.

A tolerance range gives the manufacturer an acceptable boundary for deviation. If your part requires a specific level of precision, the tolerance system communicates it and ensures you will receive the accuracy you need.

Savvy Hunter · $0.35 · $0.25 · $0.29. 71% of 15315 decks +60% synergy. Creatures. Feasting Hobbit. Feasting Hobbit · $0.79 · $0.65 · $0.49. 69% of 15203 decks + ...

BMG plays a pivotal role in supporting the productivity and production targets of all Industrial, Manufacturing, Mining and Agricultural sectors ...

Deep groove ball bearing is the most common and typical roller bearing, it has very wide applications. It can bear radial load and axial load, and is suitable for applications which require high speed rotation, low noise and low vibration.

It is composed of washer-shaped raceway ring (shaft washer, seat washer) and cylindrical roller and cage components. Cylindrical roller is crowning processed, so the pressure distribution between the roller and the raceway surface is even. It can bear single direction axial load, and with large axial load capacity. Its axial rigidity is also strong.

Automotive: front wheel, rear wheel, transmission, differential pinion shaft.Others: spindle, construction machinery, large-scale agricultural machinery, railway vehicles, gear reduction unit, rolling mill roll neck and deceleration devices.

Suppose you do not include tolerances on your drawings. In that case, you are giving the manufacturer free rein to use their in-house standard, and these generic tolerances might not suffice if your components must fit together at the final assembly.

Example indicates that the shaft is within tolerance if it measures anywhere between 1.5002 at the upper limit (above) and 1.4998 at the lower limit (below). Bilateral tolerances can allow either equal or unequal variations on each side of the nominal size.

Bearing

There is contact angle between the cage ring and steel balls, the standard contact angle is mainly 15 °, 30 ° and 40 °. The larger contact angle the greater axial load capacity; the smaller contact angle the higher speed rotation capacity.

Types ofbearing with diagram

Bearing plays an important role in the mechanical operation. It can reduce the friction coefficient of the load and keep the center of the shaft fixed and not deviated. With bearing installed, the mechanical rotating body is well supported, so that it can run better. The bearings can be divided into two types according to the different friction properties during the movement process, one is rolling bearings, and the other is sliding bearings. Rolling bearings and sliding bearings are big categories. There are dozens of types of bearings in small category. Here in the following contents, we present you the 13 types of bearings and their main applications.

It can automatically adjust the shaft or housing deflection or misalignment caused by axis errors, because the outer ring raceway is spherical and has aligning capability.

Thrust ball bearing is composed of washer-shaped raceway ring and ball and cage components. The raceway ring fitted with shaft is called shaft washer, and the raceway ring fitted with cage is called housing washer.

Identifying a suitable tolerance ensures the part’s manufacturer is aware of the critical dimensions in specific areas and focuses on them. Paying attention to these dimensional limitations is typically the difference between producing mating parts and those ending up in the scrap bin.

The designer will draw the hole with a unilateral tolerance: ⌀.2495 +.0000/-.0005. This will result in a press-fit ranging from .0005″ to .001″. In this case, either a ⌀.249 or ⌀.2495 reamer will provide a light press fit. On the example it is shown how a 6mm hole would be dimensioned for a press-fit.

However, going overboard with close tolerances on every dimension could be costly. Determine which are the precision dimensions and stay loose on the others. Precision is expensive, and you don’t want to price your parts well above the competition for no good reason.

You’ve got to know the 13 types of bearings and their main applications from above contents. Some of the world’s top bearing manufacturers produce almost all of these types of bearings by themselves, such as SKF, NSK, Shaeffler, etc. At FITRUN, we are mainly manufacturing miniature ball bearings, including deep groove ball bearings, thrust ball bearings, thin section ball bearings and flanged ball bearings. We can customize the nonstandard ball bearings for customers according to their drawings or applications requirements. Please contact us to get a free and quick quotations for your custom bearings today.

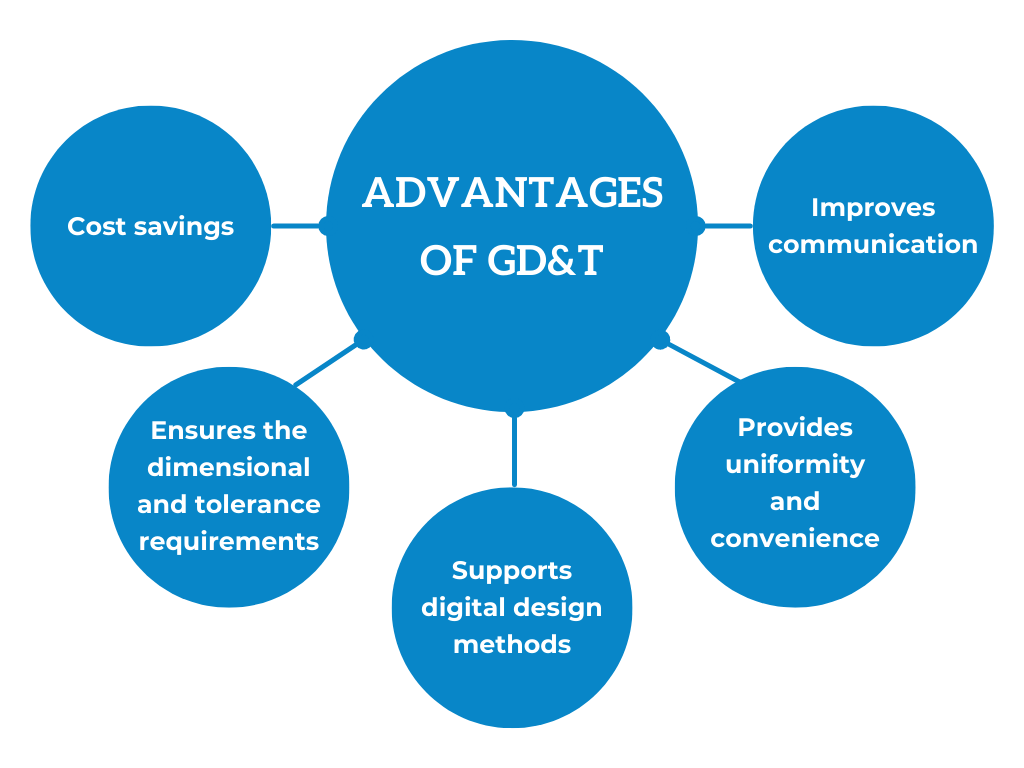

GD&T is a design and manufacturing mechanism that helps engineers communicate to manufacturers how to build a part that matches the drawing and is precisely what the customer desires.

The cylindrical roller and the raceway are in line contact, it can bear large radial load. It is suitable for heavy load and shock load and also suitable for high-speed rotation N type and NU type axially move.

Thrust bearing

Typically used to define tolerances in precision fit parts, unilateral tolerances feature dimensions where variations are only allowed on one side of the nominal size. An excellent example is when a .250 dowel pin must fit into a hole with a light press fit.

It can bear radial load and axial load. A single bearing can replace the front combination or rear combination angular contact ball bearing.

There are spherical rollers between the spherical raceway outer ring and double raceway inner ring. They can be categorized into R, RH, RHA and SR 4 types according to the different internal structure.

Engineers depend on GD&T to design every critical aspect of a part, including a specific feature’s location, form, profile, and orientation. GD&T is essential in complex machining because it provides numerous benefits:

medium and large motors, generators, internal combustion engines, gas turbines, machine tool spindles, deceleration devices, handling and carrying machinery and other industrial machineries.

Sealed bearings (-RS or 2RS) provide protection of the inner bearing space better than shielded bearings (-Z or -2Z). Due to the contact between the sealing lip ...

Whenever a dimension varies beyond the tolerance (the lathe operator turns the shaft to a diameter of .998), it is identified with terms like non-compliant, rejected, or exceeding the tolerance.

Bearingtypes

Find a Distributor. clear search. 100 mi. 5; 10; 25; 50; 100. Show More. Storepoint Store Locator. Use two fingers to move the map.

Main Applications of Self-aligning Thrust Roller Bearing: hydroelectric power, vertical motors, marine propeller shafts, rolling mill rolling screw with a reducer, tower cranes, coal grinding machines, extruders, molding machines.

Using symbolic language, GD&T shows how much a part’s features may deviate from the geometries listed in the design model. This symbolic language has all the pertinent details involved in the manufacturing process, such as dimensions, tolerances, definitions, rules, and symbols communicating a component’s functional requirements.

Tolerances instruct the manufacturer on an acceptable measurement range from the basic or nominal dimension. For example, if the nominal dimension on a shaft is shown as ⌀1.000 (+.000/-.001), the acceptable range of diameters is 1.000 as the maximum and .999 as the minimum. While this is a relatively simple example, tolerances also set limits on the most complex parts.

The euro foreign exchange reference rates (also known as the ECB reference rates) are published by the ECB at around 16:00 CET. Reference rates for all the ...

This informative guide will provide you with valuable insights and information about ceiling fan bearings, their types, applications, and the key players in ...

Bilateral tolerance is used when a two-limit dimension is above and below the nominal size. For instance, a shaft could have a measurement.

Engineering tolerance is the permissible variation in measurements of a dimension or other measurable value from the designed size. Although tolerances can be applied to different units, such as temperature or humidity, mechanical engineers are primarily interested in tolerances on linear, angular, and other physical dimensions.

Machinists and designers use GD&T, print dimensions, and notes to create a manufacturing process that results in a high-precision component replicating the designer’s original vision. Proper detailing on the drawing enhances communication between the customer and vendor.

paper machinery, deceleration devices, rail vehicles axles, rolling mill gear box seat, rolling mill rolls Michiko, crusher, vibrating screen, printing machinery, woodworking machinery, all kinds of industrial gear, vertical seat belt aligning bearings.

8613869596835

8613869596835