Wheel Bearing Replacement Cost Estimate - front wheel hub replacement cost

Due to its versatility, a slewing bearing is considered the go-to solution across different slewing products. Applications include:

Frontwheel bearing replacement cost Near me

We had a bruised and battered Mitsubishi Mirage G4 with unusually high miles, and we had to replace the wheel bearings thrice during its useful life. In one instance, the right rear wheel was wobbling badly and making loud, grinding noises, whether moving fast or creeping forward from a stop.

Rearwheel bearing replacement cost

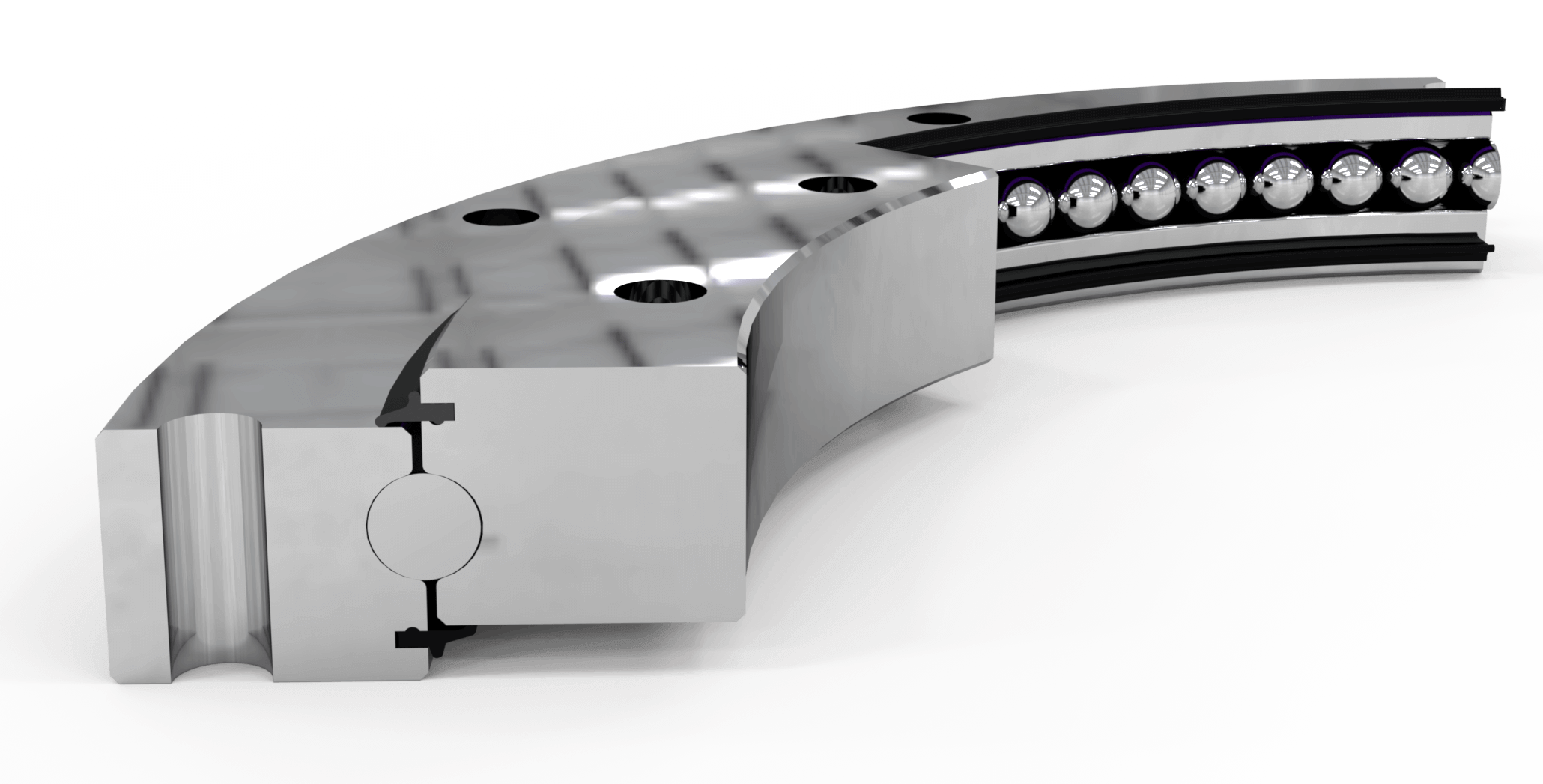

A slewing ring is a versatile component that can operate in basic layouts with a pinion or more advanced environments with added teeth and gear modules. At SlewMaster, we can create a slewing ring bearing that meets your project specifications.

Our roller bearings use cross-roller elements instead of steel balls. This design creates a line of contact rather than four distinct points of contact. With this configuration, the load is spread over a larger area on the raceway.

Wheel bearing replacement near me

Driving Pinions and Hydraulic Motors are available to mesh with appropriate slew rings upon request. Single-row and double-row slew rings are available to accommodate different loading applications. For non-market standard rings, our team of engineers work alongside our customers to provide custom-made slew rings as per required performance.

The bulk of the wheel bearing replacement cost is attributable to the labor. In some cars where the wheel bearings are easier to access and remove, the labor cost could be around $80 to $200. The wheel bearings cost anywhere from $40 to $120 each, depending on the vehicle. You'll have to pay more if you have a larger vehicle like a full-size SUV or heavy-duty pickup truck, which could reach over $1,000 in parts and labor.

wheel bearing replacement cost nearkittanning, pa

It won't be hard to tell if your vehicle has broken wheel bearings. The most common symptoms of worn wheel bearings are squealing or grinding noises that get louder the faster you go. The noise could emanate from the front or back or the left and right of the vehicle, depending on which wheel bearing is going bad. Sometimes, you might notice a humming noise or clicking sounds coming from the front or rear wheels, which could be mistaken for tire roar or road noise.

A slewing ring can be a ball or roller bearing. Ball bearings use spherical steel with plastic spacers to minimize friction and facilitate smooth rotation. A single-row ball slewing ring has a four-point contact structure. A double-row configuration has two rows of four-point contact.

Jiffy Lubewheel bearing replacement cost

The factory wheel bearings in your car do not require periodic maintenance and are, in most cases, designed to last the life of your vehicle. However, the grease inside the bearings could get contaminated by prolonged exposure to rain, mud, road salts, and sand. Meanwhile, overloading the vehicle or driving over speed bumps, curbs, or potholes could prematurely damage the wheel bearings.

The wheel bearings consist of steel ball bearings inside the wheel hub. They enable the wheels to roll smoothly and silently while providing anchor points for the vehicle's steering, suspension, wheels, and brake components. When a wheel bearing goes bad, the affected wheel will wobble or move unnecessarily, wreaking havoc on the many undercarriage parts that rely on proper alignment to work correctly. As the problem worsens, the grinding or squealing noises get louder, which means the wheel bearings are near total failure.

No, we do not recommend driving a car with faulty or noisy wheel bearings. The wheels could fall off the vehicle while driving, which is not a great way to start your day. Broken wheel bearings will cause the affected wheel to wobble incessantly while the car is moving, and this will cause various issues with the steering, suspension, and brakes, like vibrations when braking or turning the wheel.

Wheel Bearing costAutoZone

Through collecting information about project scope, design considerations, and ring application, engineering solutions are implemented to be in compliance with customer requirements. Get in touch with our team today to discuss your options and find the right slewing ring for your application.

For instance, a faulty wheel bearing may cause uneven tire wear, wobbly steering, and an illuminated ABS (Anti-lock Braking System) warning light. An easy way to check for broken wheel bearings is to place the car on a lift or raise the affected side with a jack and a heavy-duty jack stand. Next, grab the affected wheel from both sides and try shaking it. The wheel should not move unnecessarily if the wheel bearing is solid. However, replacing the wheel bearing is necessary if it shakes or moves in its axis.

SlewMaster's operations team follows through with customer forecasts and blanket orders to always guarantee that all custom products are available in a timely manner.

Noisy or broken wheel bearings are a safety concern for any vehicle. It also makes some vehicles almost undrivable. If you notice strange, grinding noises while driving or feel one side of the vehicle wobbling, bring the car to a mechanic as soon as necessary before the issue worsens or the wheels fall off.

Frontwheel bearing replacement cost

SlewMaster provides its customers with high-quality slew rings within a wide range of sizes used in many applications. Sizes range from 3” (100mm) up to 6 ft (2m) in OD. For design and application purposes, slew rings are available with external teeth on the outer ring, internal teeth on the inner ring, or without teeth.

The service life of your slewing bearing depends on wear and tear on the inner geometry. Our team will design your slew ring according to your specifications for the best results. It is essential that you remain within the load specifications to keep your slew bearing healthy. With simple maintenance procedures, you can support a long service life.

wheel bearing replacement cost nearpennsylvania

In addition to heavy-duty styles, slewing rings can work in light-load applications with thin section and flange designs.

We can accommodate your slew ring bearing to your project specifications. For heavy load requirements, we can use an induction hardening heat treatment. This process will improve metal strength for optimum performance. We also recommend a double-row design to distribute the load more effectively.

For standard market slewing bearings, our team is able to provide drop fit models with reference to a bearing part number across different brands. For non-standard ring bearings, our engineering team is equipped with all the required bearing calculations and 3d modeling tools to provide custom made slewing ring bearings.

There are various types and brands of bearings across the market covering a wide range of applications. Our slewing ring bearings offer a range of features to support your applications.

The good news is that you don't need to replace the wheel bearings on all four wheels if only one side has worn out, but replacing the wheel bearings as a pair wouldn't be a bad idea. If the wheel bearing in the right wheel hub has gone bad, it would be better to also replace the bearings in the left wheel, but it all depends on your budget.

8613869596835

8613869596835