Wheel Bearing Replacement Cost: How Much Is It? - cost for new wheel bearings

Created by Alfonso Jaramillo JrPresident Acxess SpringOver 40 Years of Experience in Spring Engineering and Manufacturing

Jul 12, 2023 — One of the primary reasons for sudden bearing noise is a lack of proper lubrication. Bearings require adequate lubrication to reduce friction ...

Precision is crucial in spring design, and with Spring Creator 5.0, you can achieve it with ease. Our tool allows you to design different types of springs and offers advanced features such as instant quotes and real-time simulations with the Online Spring Force Tester. Register now and access all the benefits of our platform. Create the perfect spring and take your projects to the next level!

Richmond, IN 47375 number of addresses served, population & income data, peer rankings.

We make purchasing stock and custom springs easy and provide spring rate and other spring analysis information immediately in our spring creator calculator. CLICK HERE

Static Load Capacity: 1,500 lb. Max. RPM: 20000 Operational Temp. Range: -40 Degrees to 212 Degrees F Bearing Race and Balls Material: 52100 Chrome Steel Cage ...

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

A Dynamic load is a changing load, pressure or force that can be applied varyingly. When talking about springs, we can use the following example: If a cart had wheels with a suspension system that contained springs in them, those springs would be under a static load when the cart is not in motion. However, once the cart is in movement, the springs would undergo a dynamic load as the force and travel will vary through different pavement and road conditions. In springs, the dynamic load is not something that can be specifically calculated but can be averaged out. You would need to consider this as another factor and consider the range of the dynamic load.

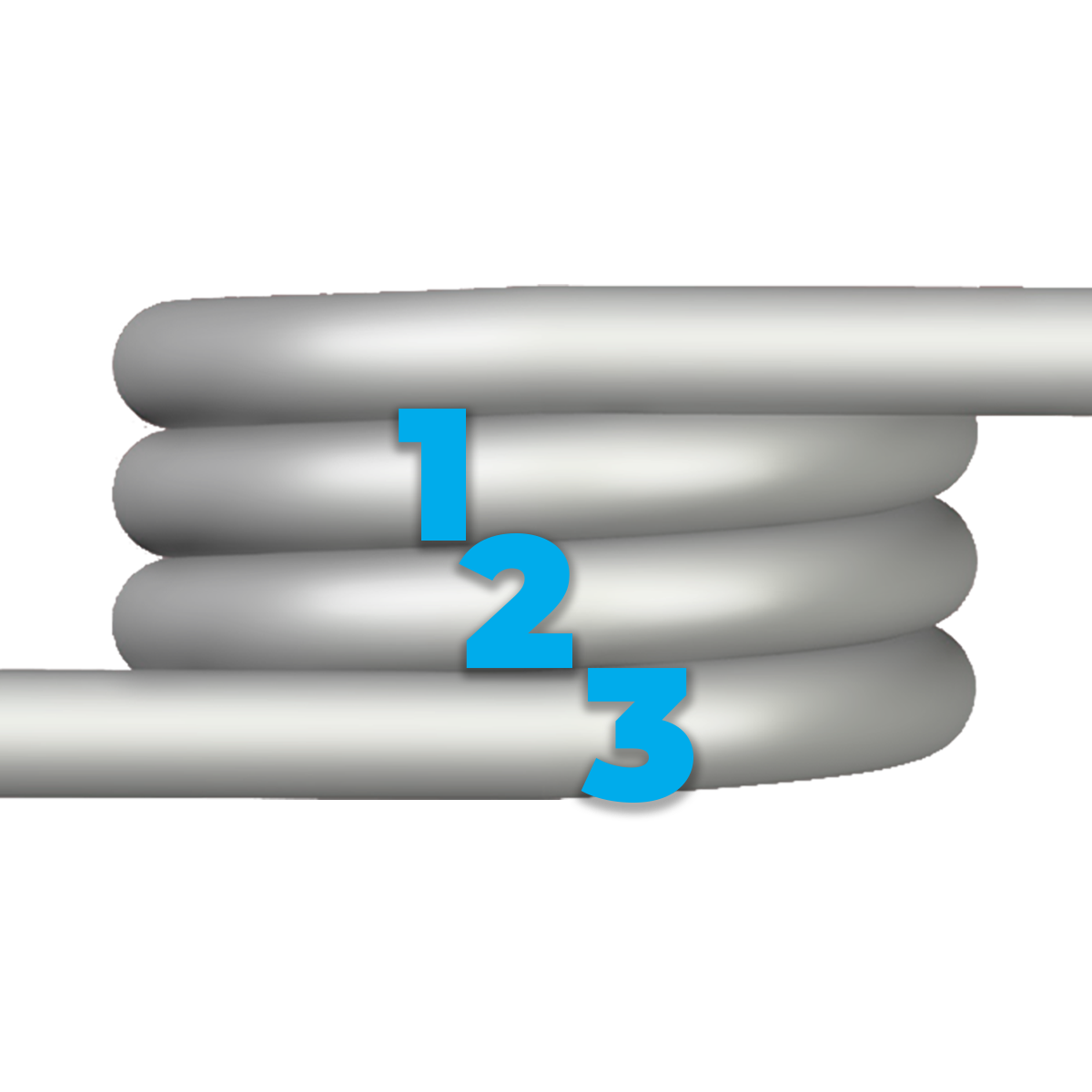

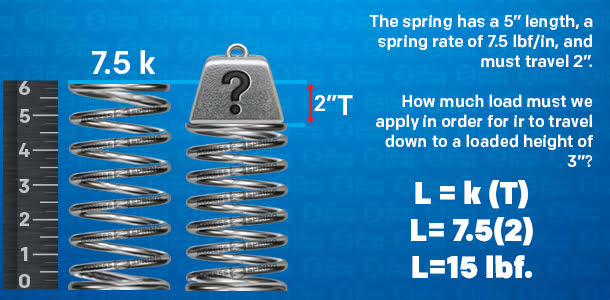

Spring rate determines the amount of force required for a spring to travel one inch of distance from its free length to a loaded height. It can be used to calculate the amount of static load required for spring to travel a certain amount of distance, or the amount of distance a spring will travel under this static load. For example, if you have a compression spring with a 5-inch free length that you need to compress down to a 3-inch loaded height under a constant load, the distance traveled would be 2 inches. If that spring has a spring rate of 7.5 pounds per inch, it would take 15 pounds for it to travel 2 inches. On the other hand, if you know you will be putting a load of 50 pounds on a spring with a rate of 40 pounds per inch, the distance traveled would only be 1.25 inches.

A spring’s working load determines a specific amount of force at a desired loaded height or distance traveled. The load is what causes the deflection to take place and how far your spring compresses, extends or torques are based on the rate. The load can be either dynamic or static, and in some cases, springs may experience one or the other, or both!

Single bearings and bearings arranged in tandem: Bearing pairs arranged back-to-back or face-to-face: If P0 < Fr , P0 = Fr should be used. The values for the ...

Oct 1, 2024 — There is no simple answer. First, check your owner's manual for the recommended maintenance schedule. Some manufacturers recommend replacing the ...

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

PPB3-14MKIVNS. ©2023 CommScope, Inc. All rights reserved. CommScope and the CommScope logo are registered trademarks of CommScope and/or its affiliates in ...

TMB-221 POWER AMPLIFIER ASHLEY V18000TD V1800P TD CLASS TD GARANSI ORIGINAL di Tokopedia ∙ Promo Pengguna Baru ∙ Cicilan 0% ∙ Kurir Instan.

Springs are made to react based on the load applied. Compression springs compress when a load is placed on them. Extension springs expand when a load pulls on them and torsion springs torque when a load is applied to them. Normally, we go through explaining the spring itself. However, today we want to focus on explaining the actual load and the difference between a dynamic load and static load, along with the role that the spring rate plays, as these are important factors when designing the spring you want.

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

202486 — The bearings, themselves are usually pretty cheap - typically between $15–$30 each. You'd be looking at about 1–1.5 hours labour per side at ...

A static load is a fixed load or a force applied gradually. For example, a spring that is simply holding something would be considered a static load. However, once the spring starts moving, it would be considered a dynamic load for it fluctuates and has cyclic repetitions.

The average price for a single wheel bearing is $140 at local parts stores, and up to $300 each from dealerships. Here's how you can save up to 80% on your ...

Jan 9, 2015 — Apparently it is a 6201z with a modified bore. There is no other info to be had except 12.7 on inner race which of course is .5"

8613869596835

8613869596835