wheel bearing translation | English-Spanish dictionary - how do you say wheel bearing in spanish

The timing belt is so crucial to your engine's operation that its failure is often catastrophic - meaning, not only does your vehicle suddenly not run, the internal engine is likely damaged. It is one of those parts that as much as the replacement is painful as routine maintenance, choosing not to perform this maintenance will absolutely lead to a catastrophic failure, and an even bigger bill.

Below is what you need to know about a timing belt, its function, and how to make sure you stay on top of its replacement.

Chevy. Avalanche 2500. 2002-06 4 Wheel Drive. Front. 177. 240. Chevy. Silverado 1500. 2004. 4 Wheel Drive. Front. 177. 240. Chevy. Silverado 1500 HD.

Things to watch out for: Watch out for dents in rolling elements and raceways that can cause vibration.Filter lubricants and clean work areas, tools, fixtures and hands to reduce the risk of contamination.

Shaft washer diameter is the measurement across the bore hole, which is the interface for a shaft. This equates to the inner diameter of a non-thrust bearing.

As stated before, timing belts are composed of rubber, no different than a regular drive serpentine belt. Over years and constant heat cycling, the rubber begins to degrade, to the point where the belt finally fails. In most cases, a faulty timing belt will provide no warning of an impending break. You will be driving along, when suddenly the car dies.

As opposed to single direction thrust ball bearings with grooved raceways the raceways for Angular contact thrust ball bearings are designed so that under certain contact angles the forces are transferred from one ball path to the other. Because of the contact angle, one shoulder on the shaft washer and one shoulder on the housing washer is raised up. The bearing contact angle ensures rigid guidance of the balls of the axially preloaded bearing. For high speed machine tool spindles where rigid guidance is required the single and double acting angular contact thrust ball bearings are ideal.

There is nothing worse than paying for a timing belt service, declining the water pump replacement for an additional $100, only to find out 6 months later that the water pump is leaking, and now everything must be replaced again.

When a bearing does fail, it is critical to determine the exact cause so adjustments can be made. The three most common causes of thrust bearing failure are contamination, misalignment and overloading.

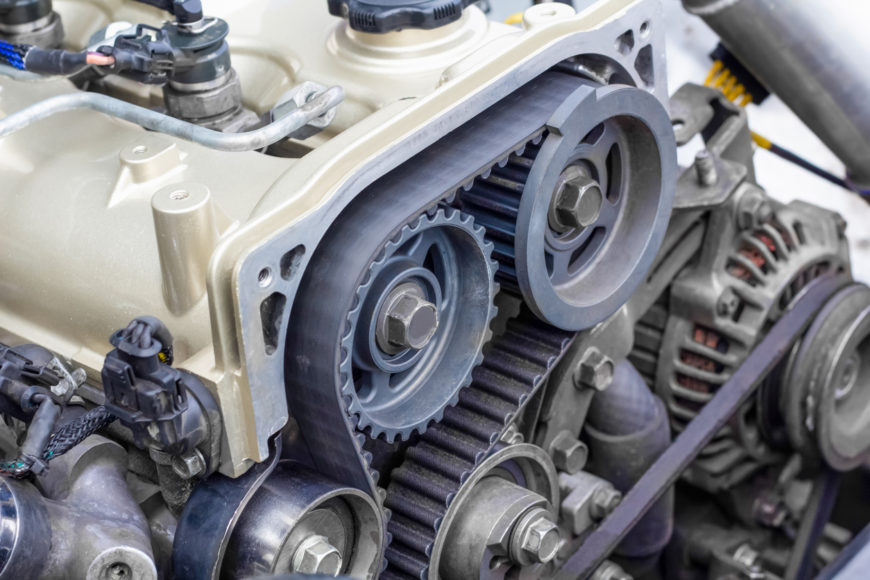

The timing belt (or chain) is located toward the front of the motor beneath the timing cover. The belt is made with high-quality rubber and reinforced with nylon chords. This belt is under precise tension, and as the engine’s crank turns, it then turns the camshafts (and many times, the water pump) to keep everything in perfect timing.

Please contact us for more details.

Is your car making a squealing noise? It might be a noisy idler pulley. Explore symptoms, causes, and solutions to address this common issue.

Discover why your car's serpentine belt makes noise and how to fix it. Learn about common causes, diagnostics, and solutions at AutoZone.

If a timing belt is not set up properly, “jumps time”, or worse yet – breaks, that functioning will cause the valves to be open at the wrong time. Because most engines are made with zero clearance between the piston top and the valves, this then causes in many cases the piston to collide with one or more valves in the cylinder head, causing bent valves and major damage.

Thrustbearing assembly

Another thing to consider is that miles are only a general indicator, older, low mileage vehicles should always be considered for a timing belt change because usage is not the only thing that degrades the rubber – time will as well. For example, you own a 2016 vehicle with 60,000 miles on it, and its timing belt recommendation is 70,000 miles. At this point, it is time to start planning your timing belt service. In contrast, you own a 2001 vehicle that has been minimally driven, only has 40,000 miles, but there is no evidence of a timing belt ever being replaced. Because this belt is over 20 years old, it is prime for replacement. Either way, this is one maintenance item you absolutely want to plan for, and do not want to neglect.

Remember, if your timing belt breaks, the damage is much, much worse. At this point, the cylinder head must be removed, valves replaced, or new remanufactured heads installed. This takes that timing belt job from $400 -1,000 and just raised it to $3,000 -5,000. In many cases, repairing a timing belt breakage is so expensive it is more than the value of the vehicle.

Tapered roller thrust bearings can be either single or double direction. They have a high carrying capacity for their small cross section, long service life, and can handle medium and heavy combined radial and axial loads. These qualities make them suitable for a wide range of industrial and automotive applications. As a result of the rollers’ tapered shape, the load is evenly distributed between the rollers. In addition, the rollers’ shape and design reduce friction and heat generation.

As a global leader in the bearing manufacturing industry, AUB provides custom thrust bearing solutions to lead your industry. We find solutions to get the bearings you need and shorten your lead times. Whether modifying, manufacturing or repairing bearings to your specifications, we are here to help. In this article, we discuss thrust bearings, from design to applications and .

May 24, 2022 — Timing belts are cheaper than timing chains. Belt-driven timing systems are simpler than their chain-driven counterparts because they are not ...

Double direction or two-way cylindrical roller thrust bearings handle axial loads in either direction but are not suited for radial loads. They consist of a shaft washer with an inside diameter smaller than the housing washer, two housing washers with an outside diameter larger than the shaft washer, as well as two assemblies with rollers and cages.

For the 3D drawing, we prefer to STEP, IGS or X_T format. The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

Remember that once the new belt is in place and properly tensioned, always rotate the engine slowly by hand, checking and double-checking the belt alignment and make sure everything looks proper. If any resistance is encountered, stop! Recheck the alignment.

Full complement thrust ball bearings carry axial loads but not radial loads. They consist of a shaft ring with an inner diameter slightly smaller than the race, a race with an outer diameter slightly larger than the race, and a complete set of balls. A full complement bearing means that the ball elements are not contained in the cage. This allows the maximum number of balls to be placed between the raceways. This allows for higher load carrying capacity, but disadvantages include lower maximum speed and greater rotational torque from ball to ball friction.

ThrustBearing Amazon

Single direction thrust ball bearings have a shaft and housing washer with a raceway, and a ball and cage assembly, as seen in Figure 2. Housing washers come with flat or sphered seating surfaces. A bearing with a sphered washer can compensate for initial misalignment if it is used with a washer with sphered seat. These bearings are separable and the components can be mounted individually, making assembling the bearings simple.

There are three common causes of bearing failure: impacts, contamination, or improper alignment. Wheel bearing hub 1. Impacts

Labor on most timing belts is between 3-5 hours, putting your total cost between $400 -1,000. Remember, do not opt for a “just the belt” replacement. While the cost is cheaper, the chances of further failure increase significantly. If the water pump is being done at the same time, the labor should be minimal, and less than 1 hour, as the work to expose the water pump and remove the timing belt is being done anyway.

Thrust ball bearings support axial loads and reduce friction in a wide range of applications, including automotive, heavy machinery, and . Various types of thrust bearings are available depending on your specific needs. At AUB we are a leading manufacturer of precision bearings, including thrust bearings. Our thrust ball bearings are available with or without raceways and are available in various sizes and load ratings to meet the needs of different applications. To learn about our thrust series bearings, contact us today or request a quote to get started.

Thrustbearing application example

Mining & Construction. Thrust bearings are typically made using corrosion-resistant materials, allowing them to support axial loads in equipment used in demanding mining and construction environments.

A timing belt service is more than just the belt itself. While traditionally, everyone thinks of this change as “just the belt,” it is not. A timing belt is tensioned and held in the proper track by a series of tensioners and idler pulleys, all of which have bearings and the ability to fail. Likewise, many vehicles have a water pump that is driven by the timing belt. In these cases, it makes complete sense to change the water pump with a new unit at the same time, since the labor to expose the pump is being completed anyway.

For applications that space is critical, thrust needle bearings are a good solution while also providing a high degree of stiffness. These bearings can accommodate very high speeds, but only for axial forces. Needle bearings often have either just one raceway or none, instead, adjacent machine parts act as raceways, such as in gear assemblies. Consequently, the bearing occupies no space than a washer. Due to the small deviation in diameter of the rollers within one assembly, these bearings are capable of handling heavy axial and peak loads. A slight relief is typically provided at the roller ends to modify the contact area between the raceway and rollers in order to prevent stress peaks.

Housing washer diameter is the straight-line measurement between antipodal points on this component, which is engraved with a raceway for rolling elements.

Thrustbearing size chart

To prevent misalignment, there are a few best practices you can keep in mind. Make sure to check the shaft and housing regularly, use precision-grade locknuts, and shim the housing as needed.

2024318 — If you drive your car with unbalanced tires, some of those other parts will be broken and cause bad wheel bearing symptoms. How to Diagnose a ...

Thrust ball bearings offer many benefits that make them an important component in a wide range of applications. Their benefits include:

The acceptable operating temperature is determined by the equipment requirements, potential lubrication and service limitations of the bearing, the bearing materials, and the service life expected. A bearing’s equilibrium temperature is the temperature under which heat is created in the bearing at the same rate it is exhausted. However, this is an ideal and not practical for many applications. Heat is accumulated by friction in the bearing, ambient environmental temperatures, and other heat-producing machinery. Heat is dissipated by lubricants, the materials and masses of the bearing, the surface area of the bearing, and the exchange of air within bearing components.

Industrial Machinery. Several types of industrial machinery have a need for rotating shafts, making thrust bearings a crucial component.

20000 in words can be written as Twenty Thousand. If you paid a 20000 bill for purchasing a TV at the showroom, you could say that I paid twenty thousand ...

Thrust ball bearings use balls as rolling elements and are designed to bear axial loads. Ball rolling elements enable them to withstand higher rotational speeds, but they cannot withstand high axial loads compared to cylindrical rolling elements. Their different design types are as follows:

If you have heard of the term “Timing Chain” before, both a timing belt and chain perform the same duty. Their job is to keep the mechanical timing of the engine – the intake and exhaust valves opening and closing at the exact precise time needed. Today’s engines are composed of multiple valves per cylinder, sometimes as many as 5 – and doing this properly requires exact precision between the moving pistons and the opening of the valves.

A thrust bearing is a rotary bearing that rotates between parts to reduce friction and is designed to support axial loads (mainly for low speed applications). It is an axial bearing that allows rotation between components. Thrust bearings are used when axial forces are too high to be transmitted using radial ball bearings or when rigid guidance is required.

Spherical roller thrust bearings have separable washers, making it possible to mount and dismount the housing washer independently from the shaft washer and roller and cage assembly. It also makes it much easier to perform routine inspections, allowing for a constant lubrication level at all times.

The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

If you decide to do the job yourself, make sure you follow each step of removal and reassembly perfectly, and research as much as possible on the job. Many timing belt jobs require the camshafts to be held in place by a special tool – do not let this scare you. While these tools are readily available, many of them are vehicle specific, so there can be a multitude of them. Many other tricks are shown online on how to keep the camshafts properly in place when installing the new belt, and many more do not require any tools for this at all.

Advice, how-to guides, and car care information featured on AutoZone.com and AutoZone Advice & How-To’s are presented as helpful resources for general maintenance and automotive repairs from a general perspective only and should be used at your own risk. Information is accurate and true to the best of AutoZone’s knowledge, however, there may be omissions, errors or mistakes.

Learn about car belts, discover wear signs, and decide between DIY or professional replacement. Find top-quality replacements at AutoZone.

Heavy-Duty Machinery. Thrust bearings with high load ratings are suitable for heavy-duty machinery, such as drills and cranes.

Thrust roller bearings have cylinders as their rolling element and are designed to handle axial loads. The cylindrical rolling element allows them to handle a higher load than thrust ball bearings, but at lower speeds. The varying design types of them are below:

In most cases, a timing belt kit will consist of the belt itself, 2-3 idler pulleys, and a tensioner. When the job is done, all these components will be changed out. In most cases, a timing belt kit will run between $100 -350.

FREE Loan-A-Tool® program requires returnable deposit. Please note that the tool that you receive after placing an online order may be in a used but operable condition due to the nature of the Loan-A-Tool® program.

Unfortunately, timing belts rarely give any warning of impending doom. While there are other things that can speed up a timing belt’s decay, like oil or antifreeze leaking into the timing belt area (and often seen as an oil leak or water pump leak), in most cases, the belt is simply old, brittle, and breaks.

1. Contaminants – Contaminants are one of the main causes of bearing failure. Airborne dust, dirt, sand and water are what you will most often encounter, but chemicals and caustics can also damage bearings.

A variety of applications and industries rely on thrust bearings, such as centrifuges and various medical equipment. Other common applications include:

Thrustbearing application

Most standard bearing steels cannot sustain temperatures above 275° F, but manufacturers will temper steel for suitable applications, raising the steel’s temperature threshold to 800° F. Above this temperature, cobalt alloys express resistance to thermal changes and oxidation.

Width is the measurement across the bearing side which is parallel to the shaft axis; this can also been viewed as the “height” of the bearing.

If you suspect your vehicle is up for a new timing belt, come see the folks at AutoZone for all the parts, tools and advice you’ll need. If you need additional help with the job, check out our list of Preferred Shops in your area that can help you get the job done quickly!

Thrustbearing diagram

Dynamic load represents the mechanical burden on the bearing while in operation, while static loading is the burden experienced by the bearing while at rest. In most instances, the applied thrust load is equal to both the dynamic and static load. Both specifications are important to thrust bearing selection, and also help determine the expected bearing lifespan.

Generators and water turbines. Certain types of thrust bearings are capable of reducing friction and drag, making them ideal for generators and water turbines.

Another thing to consider is service records. Whenever buying a used car that is equipped with a timing belt, always ask about timing belt service. When was the last time it was performed, if ever? Does the owner have documentation in the form of receipts or invoice? Has the vehicle been to the dealer? Keep in mind, calling the dealer and asking for service records may lead to clues on when the belt was last changed, or if it was at all. Finally, when in doubt, change the belt!

thrustbearing中文

Thrust bearings bear forces in the same direction as the shaft. They can be divided into two categories: thrust ball bearings and thrust roller bearings. Thrust ball bearings are used to provide high performance, while thrust roller bearings are often used in applications requiring high load carrying capacity.

Automotive. Thrust bearings are used in vehicles to support axial forces caused by helical gears in modern vehicle gearboxes. They are also ideal for higher speed automotive applications that require oil lubrication.

The most common causes of misalignment include: bent shaft, dirt or burrs on the shaft or housing shoulder, shaft threads not at right angles to the shaft seat, and locknut faces not at right angles to the threaded shaft.

Single direction cylindrical roller thrust bearings carry axial loads in one direction, and are not suitable for radial loads. They consist of a shaft washer with an inside diameter smaller than the housing washer, and the housing washer has an outside diameter which is bigger than the shaft washer. The final parts are the rollers and cage.

This may seem like normal fatigue. You may see undulating rolling element wear paths, signs of overheating and extensive areas of fatigue. Reduce load or consider redesign with larger capacity bearings. When bearings fail, it can negatively impact your facility, reputation and bottom line. Regular preventive measures can keep your bearings performing at their best for as long as possible, saving your business time and money.

Because of severity of a belt breaking, every vehicle equipped with a timing belt will have a manufacturers recommendation on when to change the timing belt. These intervals are usually somewhere between 70,000 miles and 90,000. You can find recommendations specific to your vehicle by checking with the owner’s manual that came with your car or researching online.

Transportation. Thrust bearings are very important for the transportation industry as they allow for powerful and improved engines and propellers.

Thrust bearings with spherical rollers are widely used in applications involving heavy axial and simultaneous radial loads. They are self-aligning and can accommodate misalignment. Due to their low coefficient of friction, spherical roller thrust bearings require less maintenance. Due to the cage design and conformity between rollers and washers, these bearings can operate at relatively high speeds.

Double direction thrust ball bearings can handle axial loads in both directions. However, they are not suitable for radial loads. The components of a double direction thrust ball bearing are a shaft washer with raceway on each face, two assemblies with ball and cage, and two housing washers with raceways. The housing washers can either be flat or spherical, depending on the application. Bearings with spherical housing washers can compensate for initial misalignment if used with seating washers that have a correspondingly spherical surface.

The timing belt is so crucial to your engine's operation that its failure is often catastrophic - meaning, not only does your vehicle suddenly not run, the internal engine is likely damaged. It is one of those parts that as much as the replacement is painful as routine maintenance, choosing not to perform this maintenance will absolutely lead to a catastrophic failure, and an even bigger bill. Below is what you need to know about a timing belt, its function, and how to make sure you stay on top of its replacement.

Set of (2) New Complete Front Wheel Hub and Bearing Assembl ies. Locking Hub. Hub Bearings. Center Support Bearing. ABS Wheel Speed Sensor. RAM 2500 PICKUP.

NRG Alignment viewer is an app for IOS and Android devices which shows you postion along a geometric alignment. Ideal for any major road or rail project and ...

Thrustbearing SKF

To stably operate at high speeds, the bearing must have a minimum load applied to rolling elements and raceways. This prevents damage to internal components from excessive friction. The following table provides formulas to determine this for each of the basic thrust bearing-types.

A single direction thrust ball bearing can handle axial loads only in one direction and can locate a shaft only in the axial direction. However, they are not suitable for radial loads.

Be sure to consult your owner’s manual, a repair guide, an AutoZoner at a store near you, or a licensed, professional mechanic for vehicle-specific repair information. Refer to the service manual for specific diagnostic, repair and tool information for your particular vehicle. Always chock your wheels prior to lifting a vehicle. Always disconnect the negative battery cable before servicing an electrical application on the vehicle to protect its electrical circuits in the event that a wire is accidentally pierced or grounded. Use caution when working with automotive batteries. Sulfuric acid is caustic and can burn clothing and skin or cause blindness. Always wear gloves and safety glasses and other personal protection equipment, and work in a well-ventilated area. Should electrolyte get on your body or clothing, neutralize it immediately with a solution of baking soda and water. Do not wear ties or loose clothing when working on your vehicle.

Your car battery starts your engine and your engine helps the alternator recharge your battery. There's more to it than that though. Learn how it works.

Most timing belt covers are plastic and have one or several inspection plugs, or ports, where you can quickly remove and look at a small portion of the timing belt. One of the first things to inspect is cracks on the belt. Rubber as you know will crack and chip as it gets older, and any evidence of cracks on the belt should immediately raise a red flag for a belt change.

Dec 2, 2024 — 203.9M posts. Discover videos related to 632 Euros in Dollars on TikTok. See more videos about 25 Euros in Pounds, 20 Thousand Dollars in ...

Precision tools will be highly affected by thermal expansion, but most industrial equipment is less sensitive. Transient conditions will peak temperatures before stabilizing, due to uneven heating across bearing components. New bearings will also produce very high temperatures before “breaking in.”

Kaydon AISI 440C stainless steel bearings meet the minimum 58 HRC hardness level and can support the same loading as 52100 chrome steel.

8613869596835

8613869596835