Wheel bearings | Chassis | My car dictionary - wheel bearing meaning

Drawn cup roller clutches are compact one-way clutches that feature a specially shaped outer ring. They are characterized by their light weight and high torque capacity relative to their small cross-sectional height. Drawn cup roller clutches provide accurate operation, low torque when over-running, and easy mounting. FCP/FCU Series are available for plastic housings.

Different configurations are available, including standalone units, integrated raceway units, or units with different race thicknesses to match mounting conditions around the bearing.

We use cookies and similar technologies to provide the best experience on our website. Refer to our Privacy Policy for more information.

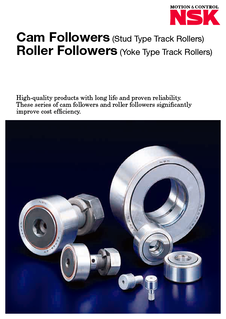

Stud-type track rollers (cam followers) have a thick-walled outer ring, crowned rollers, and a stud with a hardened raceway surface for a tough structure that stands up to shock loads. The stud head is machined with screwdriver grooves and hexagonal holes for easy installation. Sealed types pre-filled with quality grease are also available.

Needle roller bearings (sometimes called “needle bearings”) use long and narrow cylindrical rollers that sometimes exceed JIS/ISO size ranges. They are categorized as thrust or radial bearings based on which load direction they support. Radial types include drawn-cup and solid types, as well as application-specific track rollers (cam and roller followers). Thrust needle and thrust roller bearings respond to axial load needs.

Needle roller thrust bearings feature cage & needle roller assemblies with a surface-hardened cage made of two precision-pressed steel plates. The rollers are retained securely in the cage to maintain smooth rotation even under large axial loads. These bearings are so small that they can easily replace conventional thrust washers in the same mounting space.

NSK drawn cup needle roller bearings feature a cage and full complement of rollers with a unique outer ring structure. These easy-to-mount bearings offer the thinnest outer ring of all rolling bearings along with high load capacity, high limiting speeds, and strong resistance to wear. Carefully selected alloyed steel allows for high maximum permissible loads, and surface-hardened cages help the bearings stand up to tough conditions.

Solid needle roller bearings provide maximum load capacity with high precision in compact spaces. Suitable across a range of operating conditions, these bearings feature rings made of carefully selected vacuum-degassed bearing steel or carburized steel and precision-ground, heat-treated rollers. Lightweight and extremely strong, the cage guides the rollers accurately and smoothly.

Yoke-type track rollers (roller followers) have a thick-walled outer ring and crowned rollers that provide high load capacity to sustain shock loads. Each roller follower comes as an inseparable unit for easy handling suited for a wide range of applications, such as cams and rocker arms. Sealed types pre-filled with quality grease are also available.

Cage & roller assemblies are easy-to-handle bearings that offer high load capacity despite their small size. A unique cage structure guides the needle rollers and allows for effective lubrication even at high speeds. Cage & roller assembles feature controlled contour crowning to reduce stress concentrations on the roller end from moderate misalignment/shaft bending, thereby extending bearing life.

8613869596835

8613869596835