When to Replace the Timing Chain on Your Vehicle - does my car have a timing belt or timing chain

Car making grinding noise whenparked

WD Bearing manufacturing headquarters is a 20,000 m² facility with a dedicated 140 m² quality and inspection room. Our engineering labs in Europe and North America extend our quality control, service, and sales to the entire world. Our global presence ensures that our customers receive local support from our dedicated sales and service teams, regardless of their location worldwide.

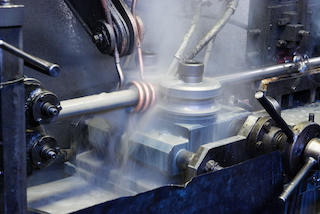

We source our high-quality 99.98% VIM-VAR steel and move it directly into our production facility where grinding, turning, heat-treating, assembly, and washing occurs. Our quality assurance and control teams constantly evaluate our product until they ship to the customer.

We have a robust selection of tapered roller bearings to fit any application you’re working with. And, of course, if you need something special, we’ve got your back there, too.

With that, the speeds of each roller are the same as the raceways along the entirety of the contact path. Given their extreme geometrical accuracy, this bearing type has ultra-low-noise and low-vibration operating characteristics during operation.

Grinding noise whenturning steering wheel at low speed

Tapered roller bearings are specialized roller bearings utilizing a separable cup and cone assembly to offer flexibility in design and installation as well as rigid performance.

Composed of a ribless outer ring, a twice-ribbed inner ring of differing heights, a set of tapered rolling elements, and a cage, WD single-row tapered roller bearings provide reliable motion under both radial and thrust, or axial, loads. Our designs advantages when compared to common tier-one competitors such as:

WD Bearing Group is a technology-oriented bearing company specializing in research & development, manufacturing, sales, and service of high-quality bearings.

Scrapingnoise whenturning left at low speed

With credit to the unique geometry of the conical rollers and their relatively large surface contact with the raceways, tapered roller bearings have a unique ability to perform under heavy axial and radial loads making them incredibly versatile bearings.

The steering wheel in your car is under direct manipulation by you. Turn it in either direction and your car responds, with the aid of other steering components in the vehicle. When turning becomes difficult or the car makes a mysterious noise when turning, you may have questions about what’s causing the trouble. Check out our list of seven common reasons your steering wheel may not be working at its best and when it’s time to steer your car toward Sun Auto Service for an inspection.

Grinding noise whenturning left only

Power steering system steering racks utilize an engine-driven pump to deliver high-pressure hydraulic fluid to the steering rack as the wheel is turned. This makes turning the steering rack easier. However, additional components such as hoses, seals, and O-rings are used for delivery of hydraulic fluid. Over time, these components begin to wear out due to usage and exposure to heat.

Given that they are fitted with tapered rollers instead of balls, higher forces can be transmitted to the bearing. An added benefit of the unique roller geometry is the ability to offer smaller rolling elements without reducing load handling ability.

Carmakesgrinding noise whenturning right but not left

In many ways the decisions made on bearings influence the overall performance and lifetime of all applications that utilize combined bearings and ultimately affect customer relationships, revenue, and perception of brand.

It is paramount to the successful operation of any OEM to carefully consider the bearings they choose. When generating motion is essentially the standard of success, what does it say when bearings are overlooked?

In many applications, it is common to see a pair of tapered roller bearings working together in tandem so axial forces can be supported regardless of direction. Most useful in applications requiring performance under heavy loads and at moderate speeds, tapered roller bearings are in use in a variety of industries including (but not limited to):

WD Bearing Group has crafted a team with hundreds of years of engineering experience collectively. Our engineers have developed applications used by NASA on the Mars rover, the construction of the World Trade Center, and numerous bearing-specific applications with popular OEMs around the world.

Often referenced as a cup and cone, tapered roller bearings use an outer ring and an inner ring assembly.. The outer ring on tapered roller bearings is known as the “cup” of the bearing while the assembly of the inner ring, rollers, and cage are called the “cone”. The inner ring assembly consists of a standard ring, a set of tapered rollers, and a cage.

Grinding noisewhile driving but not brakes applied

A specialized tapered roller bearing built to endure the greatest of loads at low to moderate rotation speeds. This configuration is used almost exclusively in the steel mill industry.

The WD tapered roller bearing design allows for heavy combined loads with very little friction.

A double row tapered roller bearing features a tandem pair of single row tapered roller bearings in a mirrored or a series configuration allowing for an even greater load distribution across the bearing assembly.

Front endgrinding noise whenturning

Enter your email address and we'll email you a digital version of this coupon that you can present on your mobile device at your Sun Auto Service Shop.

WD offers both face-to-face, back-to-back, or tandem configurations to be flexible to your application needs.

Intermittentgrinding noise whendriving

WD Bearing Group produces the whole range of tapered roller bearings, both inch and metric designs. Customized tapered roller bearings are available to fit your application as well as a risk-free application review where we provide our engineering recommendations to improve your application or reduce your operating costs.

The raceways on these bearings are not parallel. Instead, the raceways are angled to allow for both radial and axial loading. To prevent the rollers from leaving the raceway, raceways are tapered allowing for the axis of rollers to be positioned in a way where their faces converge to a common point. To prevent the conical rollers from escaping this configuration, inner rings are outfitted with a flange to stabilize their rotation.

And with regards to tailored fit and function, the load capacity of tapered roller bearings is easily adjusted by changing the contact angle of the rollers (typically between 10° and 30°) against the raceway. The higher the degree of angle, the greater the contact and subsequently the greater load capacity one can expect.

The most versatile bearings in the world - flexible designs, rigid stability, and high load capacity. WD tapered roller bearings feature a cup and cone assembly designed to maximze axial and radial loads with ultra-low friction, vibration, and noise.

All bearings, including tapered roller bearings, require visual inspections and regular maintenance to increase longevity and maintain productivity. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review . We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue .

Tapered roller bearings are particularly efficient in this regard due to the conical shape of the rollers combined with the tapered angle of the bearing rings. This allows the conical rollers to move axially together without sliding motion between the mating components.

The technology and purpose of tapered roller bearings can be similarly matched to angular contact ball bearings.

Without question, tapered roller bearings are one of the most widely used bearings types on the planet, acceptable for any application that utilizes rotating axles and transmission shafts. Combined with modern lubricants , they are as durable as they are versatile.

Turning your vehicle should not require much effort and when it does, or you hear a noise when turning the steering wheel, your steering system will need to be inspected by a qualified technician. When you need to be sure your vehicle is steering you in the right direction, visit Sun Auto Service for a proper inspection. Our technicians will provide an in-depth examination of your steering system to determine the cause of your vehicle’s steering troubles and repair them if necessary. Repairs are guaranteed in writing with a 2-year 24,000-mile nationwide warranty to provide you peace of mind for miles. Turn your wheel toward the nearest Sun Auto Service location to you, today!

8613869596835

8613869596835