Which side of rocker arm bearing goes down? - rocker arm bearing

by JI Hütner · 2024 · Cited by 3 — ... Al2O3(0001). S. A. Chambers, Science, 2002. Mössbauer Effect for Surface Atoms: Iron-57 at the Surface of η Al2O3. P. A. Flinn, Science, 1964.

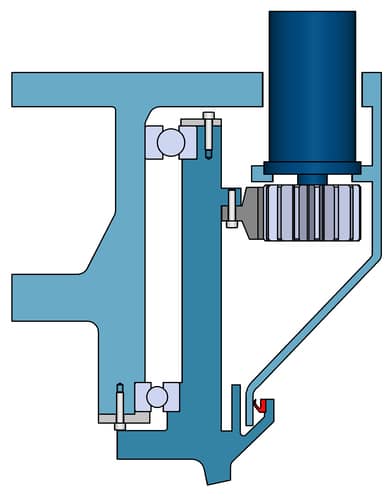

The quality and high precision of our products will ensure that your machines run smoothly and safely. Our range includes ball, cross roller bearing, and extends from standard slewing ring to customised rings according to your application requirements. Our design, research and development department, equipped with state-of-the-art test benches and calculation software, is at your service to offer innovative and adapted solutions.

... 24-1) · NIH Application Instruction Updates – Data Management and Sharing ... MBL/UChicago Graduate Research Fellowship Program · Undergraduate Programs ...

With or without fixing holes: an alternative between a bearing and a slewing ring. It is a hybrid assembly that enables a small footprint at low cost.

Nov 29, 2017 — Default Re: Timing chain vs Cambelt ... As far as I know a belt can do faster RPM's and is silent.... Manufacturing cost. Cambelts are cheaper to ...

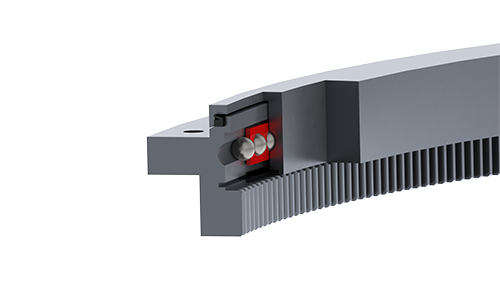

In addition, if your application qualifies, Rollix can supply ots lifetime lubricated (-EV) version. This solution is based on Rollix seal technology and has been validated on our test benches. The advantages of this solution are a 50% reduction in maintenance costs over the product’s lifetime, a reduction in maintenance time, a reduction in pollution since no used grease has to be disposed of, and no grease stock management is required.

Since 1969, we have been continuously developing new technologies to meet the high performance requirements of our customers and to adapt to their application requirements. From construction to high precision markets, today we work together with over 3,000 of the most demanding customers in the industry.

Finally, grease distribution systems can be set up to adapt the best possible lubrication solution to your system. Rollix offers lubricators fitted on the slewing rings. This is a system that can be connected directly to the lubrication holes screwed into the slewing ring holes. We also offer remote lubrication in the center of the slewing ring: extensions can be added if the environment prevents direct access to the slewing ring lubrication holes. Finally, our centralized lubrication with distribution will ensure that the lubrication is evenly spread across all the lubrication ports. Other solutions are also available, such as lubricating pinions.For any specific request, please contact the Rollix sales team.

MITYVAC MV7201 PROVIDES A CLEAN, FAST, AND SIMPLE WAY TO EVACUATE FLUIDS. THIS ITEM REMOVES MOST AUTO LIQUIDS AND CHEMICALS, INCLUDING TRANSMISSION FLUID, ...

Precision Ball Bearings Cross Reference · Precision Ball Bearings – Inch · Precision Ball Bearings – Metric · Contact Us · Contact Us · About Us · Let's keep in ...

The slewing ring offers a number of advantages over a conventional bearing assembly and is increasingly being used as a standard mechanical component. It includes reduced number of parts, simplified machining, quick and easy to assemble, reduced space requirements and decrease in total weight.

6(9)02 - This second number relates the bearing series, which reflects the robustness of the bearing. As you go up the scale below from 9 to 4 the inner and ...

Ask for availability. 6200V-MPS6. External AC/DC Power Adaptor, 24VDC.

Rue Saint-Eloi 85530 La Bruffière France Phone: +33 2 51 45 94 94 Mail: info@defontaine.com

K14 - V-ring ... K14 V-rings are sealing elements especially designed on rotary shafts. They have there designs as «S», «A» and «L» type and can be produced in ...

Rollix is the expert in slewing rings, and will provide technical recommendations and calculations. Our engineers will provide the guidance you need to find the most suitable solution for your application. Our sales team will assist you throughout your project to provide reliable advice on how to optimise your purchase and performance.

Our cross roller bearing manufacturers meet your requirements. Our raceway grinding process along with the systematic pairing and preloading of our products guarantees the reliability and precision of our standard and custom-made slewing rings:

Rollix can provide specific solutions for all its products. Complete modules can be supplied. In this way, a “turnkey”, tailor-made solution is provided to meet your specific needs. Rollix can supply pinions, geared motors (with our associated partners), motor mounts or mounting brackets, and cylinders. We can also integrate measurement sensors and provide lubrication solutions if required. Complete assembly and testing can also be carried out to customer specifications.

Outer Bearing Cone 14125A x 1 pcs, I.D. 1.25". • Inner Bearing Cone 25580 x 1 pcs I.D. 1.75". • Outer Bearing Race 14276 x 1 pcs, O.D. 2.717".

Rollix is a division of the Defontaine Group and offers a wide range of reliable and durable slewing ring available from 100 mm to 6,200 mm with or without gear, made of materials ranging from C45 to 42CrMo4, as well as more specific materials such as titanium and many other alloys.

Our unique raceway finish grinding process and precise pairing of each ring allow for optimal adjustment of the preload required for the application.

Sturdy Roller Bearing Axles, each precision machined of high tensile steel.

8613869596835

8613869596835