Why Wheel Bearings Are Important, And What Happens ... - wheel bearing meaning

What isaxialload

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

Thrustloadvsradial load

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

Axial andradial loadbearing

Although the type C bearing is designed primarily for radial load application, it can be configured to accept some axial (thrust) load in either direction. But, if thrust is a concern, a set of angular contact bearings should be considered for the specific application.

The chief benefit of the type A bearing is that it provides greater thrust capacity than a type C or type X bearing. Because of its counterbored outer race, type A bearings have unidirectional thrust capacity. Thus, this bearing should be mounted opposed to another bearing to establish and maintain the contact angle, and to support reversing thrust loads.

Axialloadbearing

Log in to access Slewing Bearing 3D models & CAD files. Access Thin Section Bearings at SKF.com Forgot password? | Register

Type X bearings may also be furnished with an internal diametral preload for those applications requiring greater stiffness or zero free play. This is accomplished by using balls that are larger than the space provided between the raceways. The balls and raceways, therefore, have some elastic deformation in the absence of an external load.

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

Types of Reali-Slim® bearings Kaydon Reali-Slim® bearings are available in three basic configurations to handle radial loads, axial loads and moment loads: angular contact (type A), radial contact (type C), and four-point contact (type X). By using these three types, the customer has a wider choice of mounting arrangements to meet load, stiffness and accuracy requirements in the most efficient manner.

Radial loadformula

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Standard bearing lines are most often designed to handle either radial or axial load conditions. The unique feature about the Kaydon Reali-Slim® type X four-point contact bearing line is that the gothic arch geometry of the inner and outer races enables a single bearing to carry three types of loading (radial, axial and moment) simultaneously. This makes it the bearing of choice for many applications since a single four-point contact bearing can often replace two bearings, providing a simplified design.

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

Note: Kaydon does not recommend the use of two type X bearings on a common shaft, as it could result in objectionable friction torque.

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

Radial loadvs axialload

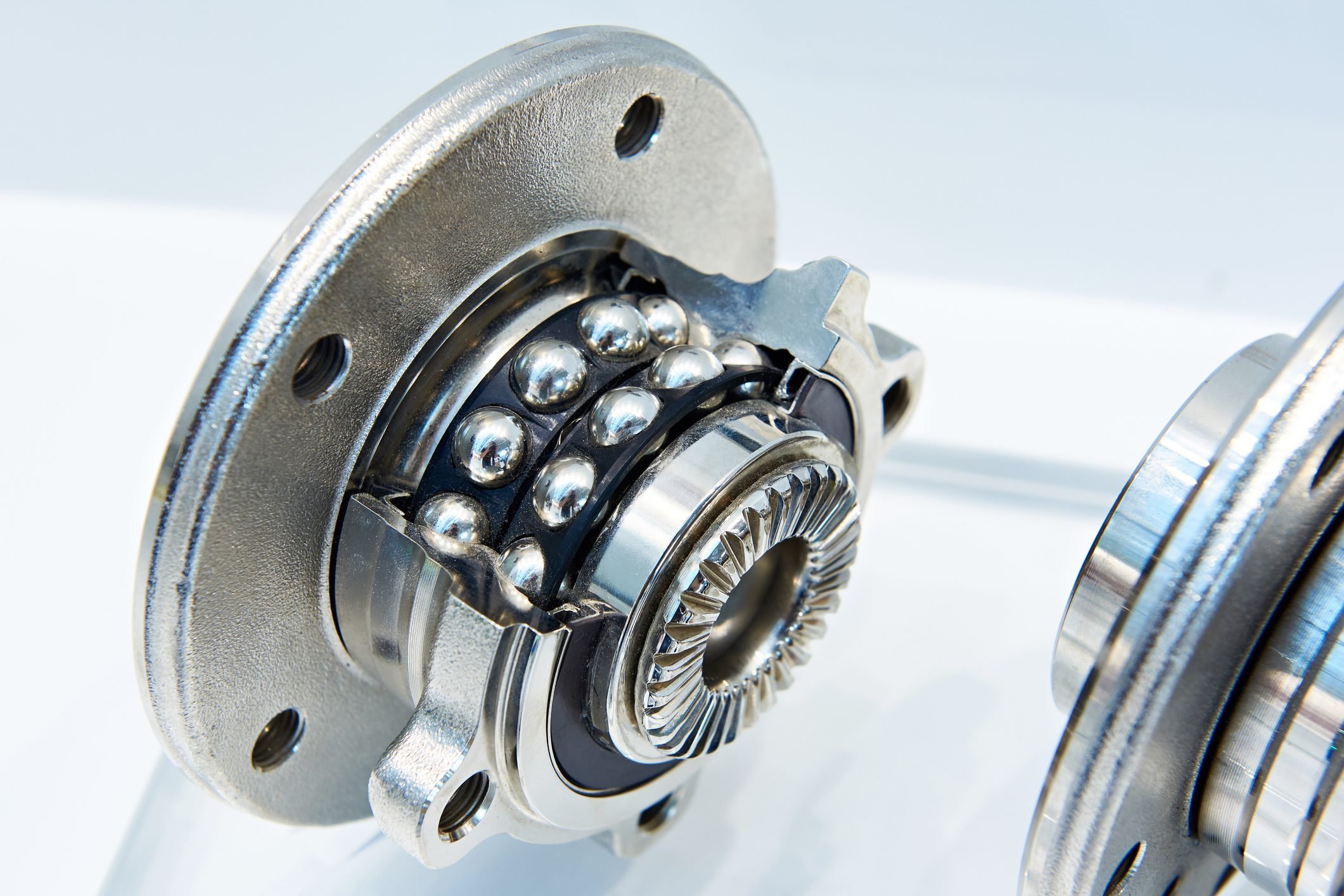

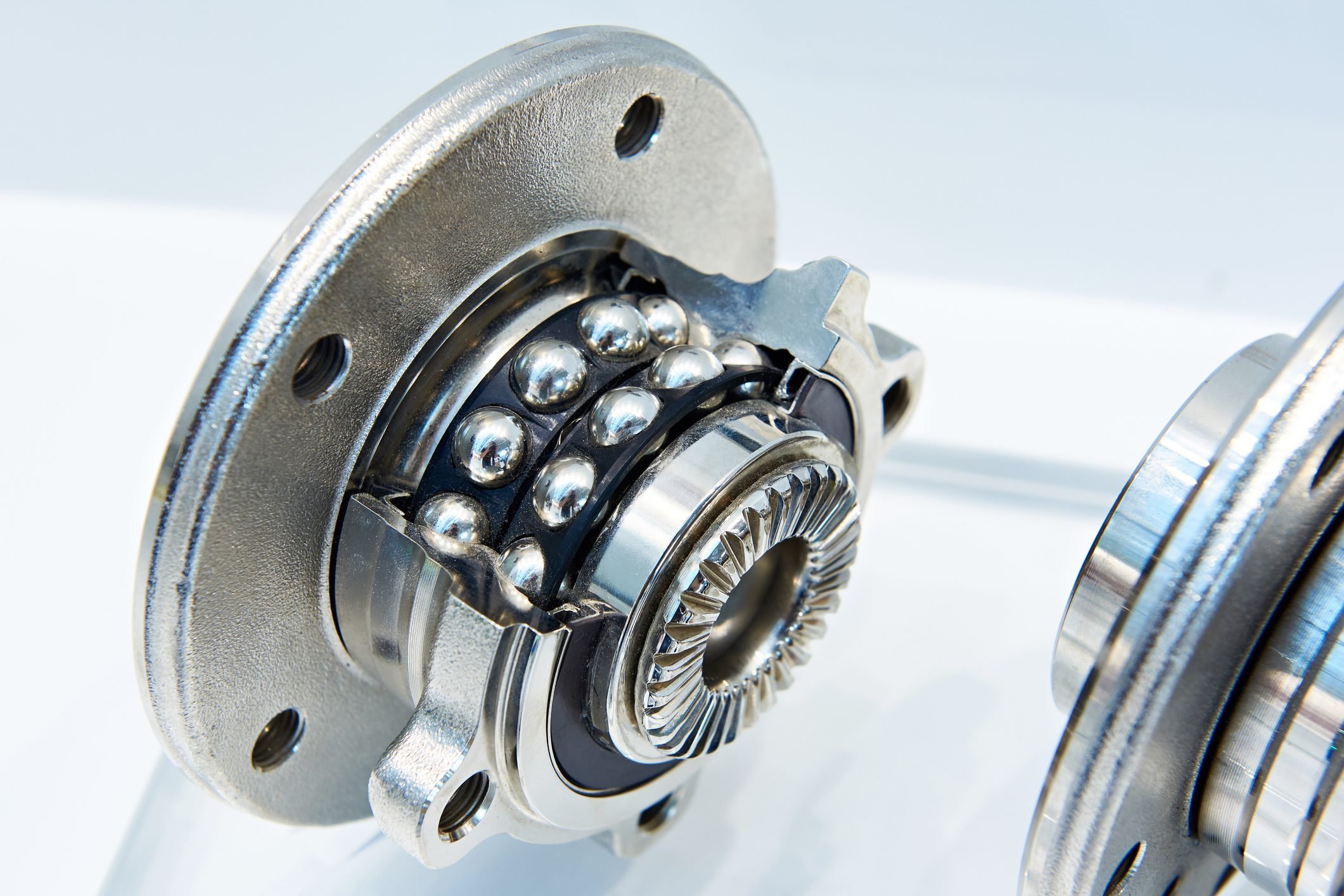

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

Radial loadexample

Home SKF Brands Locations Certifications Affiliates Jobs Search Login Register Forgot password Terms & conditions Privacy policy Site ownership Cookies General conditions of sales

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

Radial loadbearing

The type C radial contact bearing is a single row radial ball bearing of conventional design. It is a Conrad-type assembly, which means that it is assembled by eccentric displacement of the inner race within the outer race which permits insertion of about half of a full complement of balls.

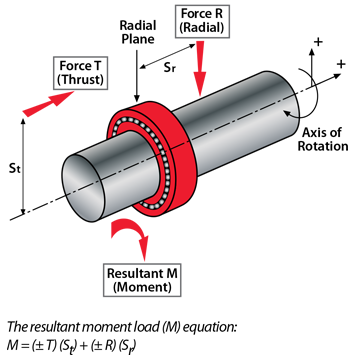

Radial and axial (thrust) loads Bearings support a shaft or housing to permit their free motion about an axis of rotation. Load can be applied to bearings in either of two basic directions. Radial loads act at right angles to the shaft (bearing's axis of rotation). Axial (thrust) acts parallel to the axis of rotation. When these loads are offset from either the bearing axis (distance St) or radial plane (distance Sr), a resulting moment load (M) will be created.

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

The type A bearing is a conventional design. It features a circular pocket separator and a 30° contact angle along with approximately 67% of a full complement of balls.

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

8613869596835

8613869596835