WIX Filters Fuel Filters 495-33011 - 33011

Where to buygrease for ball bearings

Grease lubricants have three main components: base oil, thickeners, and additives, such as rust inhibitors. Besides, grease is the better lubrication choice for linear guide and drive applications. That’s because it sticks to the bearing surfaces longer and is better than oil lubricants. Besides, it is less likely to run off or get ejected from rotating parts.

How to usegrease for ball bearings

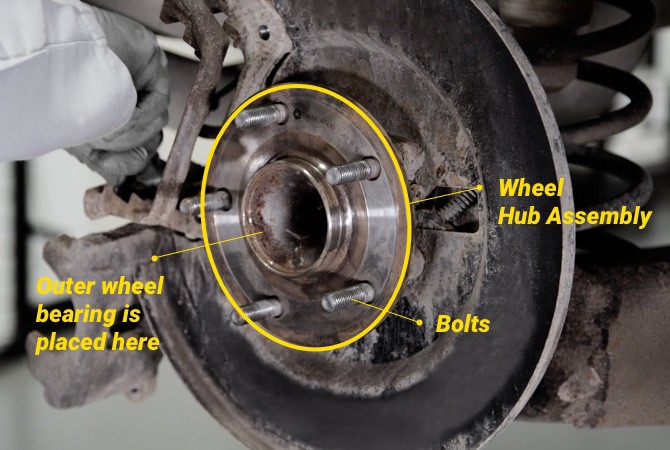

First and foremost, the wheel hub assembly keeps your wheel attached to your vehicle and allows the wheels to freely turn enabling you to safely steer.

High Speed Bearing Oil

Driving with a bad wheel hub assembly is dangerous. As the bearings inside the assembly become worn out, they can cause the wheels to stop turning smoothly. Your vehicle can become shaky and the wheels not secure. In addition, if the hub assembly degrades, the steel can fracture and cause the wheel to come off.

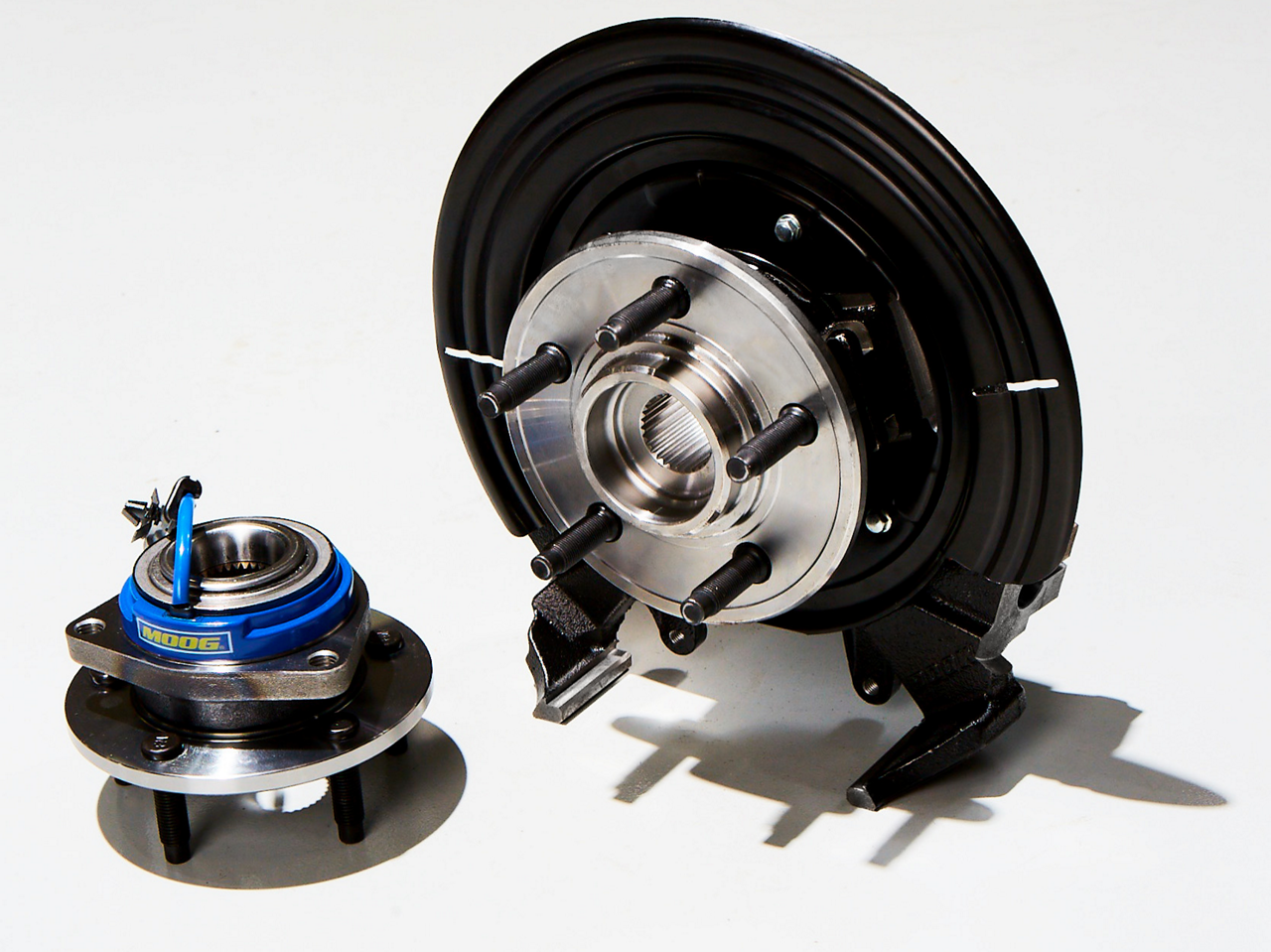

Responsible for attaching the wheel to the car, a wheel hub assembly is a pre-assembled unit that features precision bearings, seals and sensors. Also called a wheel hub bearing, hub assembly, wheel hub unit or hub and bearing assembly, the wheel hub assembly is a crucial part of your steering system contributing to the safe steering and handling of your vehicle.

On most late-model vehicles manufactured since 1998, there is a wheel hub assembly in each wheel. When the assembly goes bad, it is removed and replaced with a new assembly. On cars made before 1997, front wheel drive cars use wheel hub assemblies at each wheel and rear wheel drive vehicles use two individual bearings and seals in both front wheels. Unlike a wheel hub assembly, bearings can be serviced.

Bearing oil vsgrease

Bestgrease for ball bearings

From safely negotiating a tight turn on a winding country road to changing lanes on the freeway, you depend on your vehicle to steer exactly where you want it to every time you jump in the driver’s seat. Have you ever thought about what enables you to turn left and right and go straight down the road? You might be surprised to learn that small part called a wheel hub assembly is a key component of your steering system.

Bestgrease for bearings

Lack of bearing lubrication can result in bearing failure. Lubrication helps separate ball or roller bearings from the raceways, minimizing wear and friction. It also helps prevent corrosion and promotes the smooth running of the seals to reduce seal wear. As a result, it improves the effectiveness of the seals in keeping the lubrication within them.

Privacy Policy | Cookie Settings | Cookie Notice | Terms & Conditions | Anti-Human Trafficking | Warranty ©2022 DRiV Incorporated. All rights reserved.

On each wheel, you’ll find the wheel hub assembly between the drive axle and the brake drums or discs. On the brake disc side, the wheel is attached to the bolts of the wheel hub assembly. While on the side of the drive axle, the hub assembly is mounted to the steering knuckle either as a bolt-on or press-in assembly.

Bearinggreasetypes and grades

You can pick a lubricant that’s best for your application now that you know the operating conditions of oil and grease lubricants. For example, if the operating temperature for the bearings is high and requires faster heat dissipation, opt for oil lubrication. On the other hand, grease provides better seals against contaminants and is ideal for leakage control.

Ballbearing oil

The wheel hub assembly is also critical to your anti-lock braking system (ABS) and the traction control system (TCS). Besides bearings, hub assemblies contain the wheel speed sensor that controls your vehicle’s ABS braking system. The sensor constantly relays to the ABS control system how fast each wheel is turning. In a hard braking situation, the system uses the information to determine if anti-locking braking is needed.

There are two types of lubrications for bearing application: oil vs grease. Both are helpful in lubricating rotation bearings to avoid damage due to bearing-to-bearing contact. However, there are a few differences in their applications and elements. For example, grease is oil mixed with thickeners and other additives.

Oil lubrication is ideal for high-temperature and high-speed applications that require heat transfer away from the moving bearing surfaces. An oil lubricant flows, disperses, and dissipates heat better than grease. Oil lubrications can be synthetic or mineral, depending on the base compound. Besides, they have varying viscosities.

Your vehicle’s traction control system also uses the ABS wheel sensors to operate. Considered an extension of the anti-lock braking system, the TCS system and ABS system work together to help you keep control of your car. If this sensor fails, it can compromise your anti-lock braking system and your traction control system.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

Now that you know the difference between oil vs grease for bearing lubrication, you must choose an option that matches your applications. However, you must maintain the right amount of lubrication to achieve optimum bearing life. Most importantly, buy high-quality lubricants from a reputable company like Lubchem, oil or grease.

8613869596835

8613869596835