Xtrackers MSCI USA UCITS ETF, XD9C:BRN performance - xtracker

These bearings are designed to support axial loads in all directions and have a high load-carrying capacity. They can handle radial loads, though these are limited for a given axial load. They are separable and require less axial space compared to double-row bearings.

Ball bearings for pump applications are built to withstand harsh conditions, including inadequate lubrication, high loads, and elevated operating temperatures.

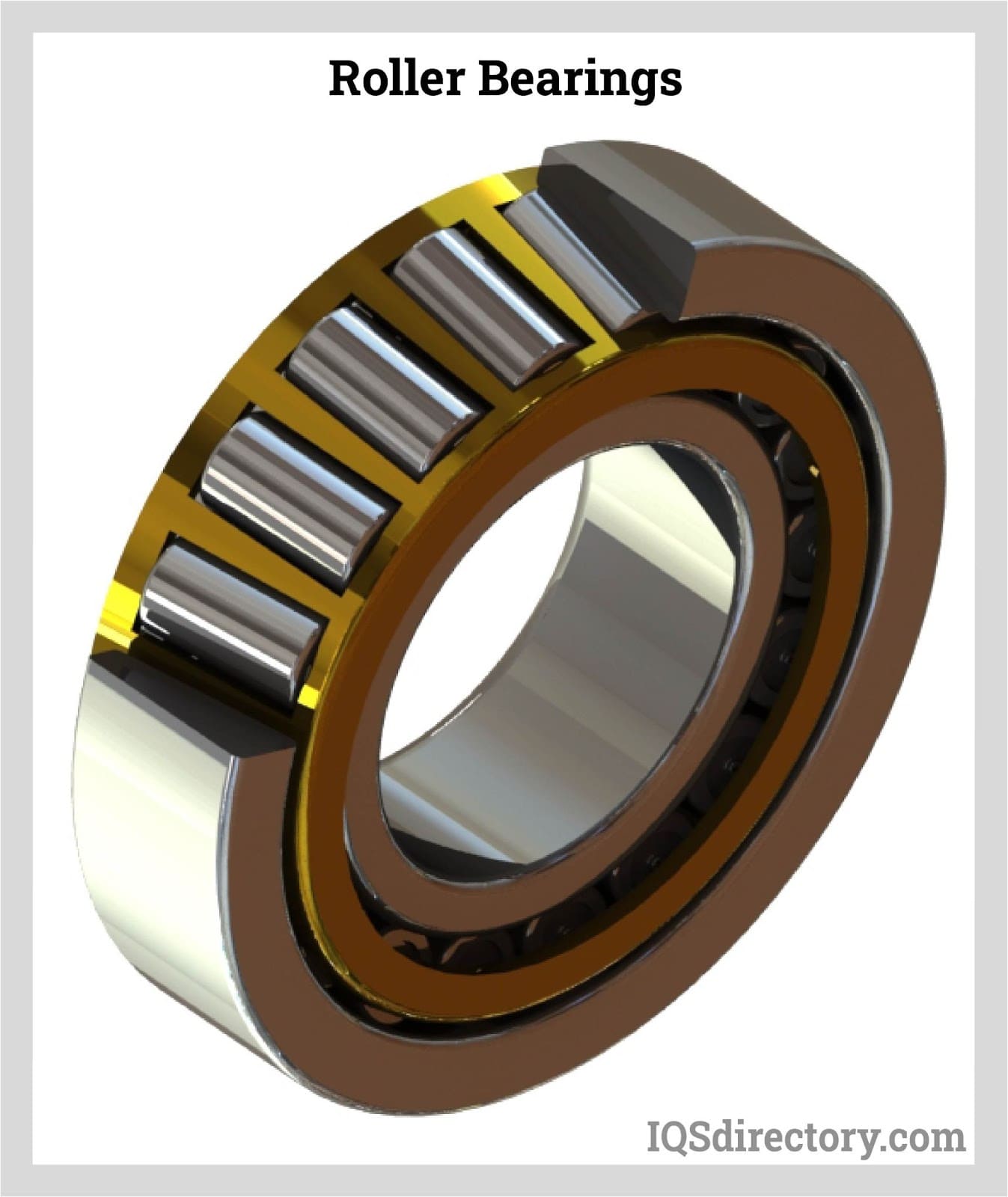

Martensitic chrome steel balls are ideal for ball bearings due to their stability and durability during continuous operation. These balls are robust and resistant to wear. Roller bearing steel, used for needle and cylindrical rollers, also offers durability and resistance to corrosion, making it well-suited for demanding applications.

Electric actuators are devices capable of creating motion of a load, or an action that requires a force like clamping, making use of an electric motor to create the force that is necessary...

Ball bearings are rolling elements that facilitate motion while reducing friction in moving machine parts. There are different materials that are used to produce ball bearings including steel, plastic, ceramics, etc. each type of material exhibits its own properties which makes it unique. There are also many different types of ball bearings including angular contact ball bearings, steel made ball bearings, deep groove ball bearings, and some are further classified into subgroups, with each subgroup having differences from the other one.

Bearings intended for the sports and consumer goods markets include those used in skateboards, inline skates, and fishing reels.

Double row deep groove ball bearings are ideal for applications where the load capacity of a single row is insufficient. These bearings are slightly wider than their single-row counterparts in the 63 and 62 series, while maintaining the same bore and outer diameter. They offer a significantly higher load-carrying capacity. Typically, double row deep groove bearings are available only as open bearings, lacking seals or shields.

Ball bearings are a type of rolling-element bearing designed to support loads, minimize friction, and help position moving parts within machinery, enabling smooth motion.

Chevy EquinoxrearWheel Bearingreplacement

While angular contact bearings are adept at handling thrust loads or a mix of radial and thrust loads, they cannot support radial loads alone. They are capable of accommodating thrust loads in both directions when arranged face-to-face or back-to-back.

A standard number system is used by the bearing industry, for bearings having metric diameter bores. To obtain the bore in millimeters, multiply bore sizes that are 04 and up by 5. If the bore is a hex, this will be referring to the dimension across the flats. If the ball is tapered, this will be referring to the smaller diameter.

The essential specifications of ball bearings include their dimensions and operating characteristics, which will be discussed below.

A linear actuator actuates, moves, in a linear, straight, line to complete or start a process. There are a variety of terms used to describe a linear actuator such as ram, piston, or activator...

If a housed unit, the outside diameter of a ball bearing does include the housing but doesnât include the flange if a flanged bearing. The overall width of the outside of the bearing is the outer ring width.

A roller table is a small, stiff, limited linear guide device with an integrated cross-roller guide. Electrical or mechanical drive systems are frequently used to move a roller table, making it easy to transfer heavy loads...

This category of ball bearings features a dual-row ball arrangement. The outer ring is typically shaped with a spherical raceway, while the inner ring contains deep and continuous raceway grooves.

This category of ball bearings is specially engineered to handle axial loads exclusively. They are not suited for supporting radial loads.

Bearings used in airframe and aircraft control are specifically engineered to meet the rigorous requirements of aerospace applications. They come in various designs, including roller, ball, and needle roller configurations.

These are small bearings having balls as their rolling element. Miniature bearings are sometimes referred to as micro bearings or instrument bearings with inner and outer rings, snap rings, balls, and retainers. These types of bearings are utilized in industrial and medical handpieces and other precision applications. Ball bearing designs include angular, radial, thrust, and pivot.

Miniature ball bearings provide exceptional precision and reduced friction, enabling high rotational speeds while minimizing noise, energy consumption, heat generation, and wear. They are also cost-effective and are designed to be interchangeable, adhering to national or international dimensional standards.

Balls made from silicon nitride ceramic are lightweight yet exceptionally tough and corrosion-resistant. While they are highly resistant to many acids and base solutions, they can be affected by certain corrosive substances. Silicon nitride also has insulating properties. These balls are self-lubricating and exhibit excellent resistance to temperature fluctuations, which can be beneficial for performance. However, silicon nitride balls are significantly more expensive than those made from aluminum oxide. They typically have a black, mother-of-pearl color.

DB and DF duplex bearings can handle axial and radial loads in both directions. When a significant axial load is applied in one direction and it is crucial to distribute the load evenly across each bearing, the type DT configuration is used.

Ceramic bearing balls can be up to 40% lighter than their steel counterparts, depending on the material and size. This reduction in weight leads to lower centrifugal forces and minimizes skidding, allowing hybrid ceramic ball bearings to achieve speeds that are 20% to 40% higher compared to traditional bearings. Essentially, this means that the inward force exerted on the ball by the outer race groove during rotation is reduced.

These ball bearings consist of three rings, with the central ring attached to the shaft. Some models include a thrust ball bearing with an aligning seat washer positioned under the housing washer to address mounting errors or shaft misalignment. Smaller bearings typically use pressed steel cages, whereas larger ones employ machined cages.

These ball bearings feature ring components resembling washers, each with raceway grooves. The ring mounted on the shaft is called the shaft washer or inner ring, while the ring fixed to the housing is referred to as the housing washer or outer ring.

These bearings are engineered for high performance, providing dependable operation under moderate thrust and radial loads while maintaining low operating torque. Key attributes of miniature bearings include precision, speed, and durability. Additionally, noise reduction at high speeds can be crucial. Due to their limited material usage, many miniature bearings are manufactured from stainless steel, and they are generally not suited for high-load applications.

These bearings are among the most prevalent types in use. They are extensively utilized across various applications. The raceway grooves in both the inner and outer rings feature circular arcs with a slightly larger radius than the balls. These bearings can handle both radial and axial loads in either direction. They are characterized by low friction, making them ideal for high-speed applications where minimal power loss is crucial. Typically, these bearings are available in open designs or with steel shields or rubber seals on one or both sides, and they are often pre-lubricated with grease.

These types of bearings allow for extra fine precision and tolerance. Precision ball bearings are ideal for applications having stringent requirements for speed and guidance accuracy. Precision ball bearings are available in two main types which are angular contact bearings and deep groove bearings. Deep groove ball bearings have full shoulders on either side of the raceways of the inner and outer ring, allowing for the addition of seals or shields with ease.

The outer race remains stationary and is mounted in the housing. It helps transfer the radial load from the bearing to the housing. The inner race, mounted on the rotating shaft, supports and guides the shaft during rotation. The rolling elements are responsible for carrying and distributing the load across the raceways.

To achieve optimal bearing life, it is essential that the contact surface between the balls and raceways is minimized and that proper lubrication is provided. Ball bearings must accommodate various types of loads, including dynamic and static, as well as radial and axial loads. Therefore, it is important to consider these four variables when determining the operating loads for a bearing.

These ball bearings are constructed by pairing two angular contact bearings. They can be arranged in several configurations: back-to-back (designated DB), face-to-face (designated DF, with the outer ring faces oriented towards each other), or in a tandem arrangement where both faces of the rings are aligned in the same direction (designated DT).

Chevy Equinox wheel bearingreplacement cost

Linear Rails are ideal for moving items through a production process with great precision and as little friction as possible if creating, packing, and distributing products. Linear Rail is a type of gadget that...

Deep groove ball bearings are the most commonly used type of ball bearings. They are available in shielded, sealed, and snap-ring arrangements. The dimensions of the race in these bearings closely match the dimensions of the contained balls. They are capable of supporting heavy loads and offer both axial and radial support.

Borosilicate glass is significantly more expensive than soda-lime glass but offers superior chemical resistance, making it suitable for applications involving strong acids. The advantages of borosilicate glass are outlined below:

These bearings are designed to manage thrust loads, radial loads, or a combination of both. They come in various sizes, including miniature precision types, and can be equipped with different cage designs. Deep groove bearings are highly versatile and are among the most commonly used types of bearings.

There are many different types of bearings made from stainless steel available. There are ball bearings made from hardened steel for hobby projects or professional work requirements. Steel ball bearings are durable and they are resistant to corrosion.

These bearings feature raceways on both the inner and outer rings that are offset along the bearing axis. This design allows them to handle combined loads, including both axial and radial forces, simultaneously. They come in various designs and can be equipped with shields or seals for added protection.

Miniature bearings are produced to conform to standard European metric dimensions, typically measuring less than 20 millimeters. They come in sizes ranging from just a quarter inch in diameter up to 20 millimeters. Among the smallest variants are those with a bore of 0.04 inches and an overall diameter of a quarter inch. Their compact size makes them versatile for various applications.

Ball bearings of this kind are highly adaptable. They find use in various applications, from arts and crafts and bicycle maintenance to precision machinery, model engineering, and numerous experimental projects.

These ball bearings come in both sealed and open variations. They are designed to handle angular misalignment between the shaft and the housing, which might occur due to shaft deflection, without issues.

Linear slides, also referred to as linear guides or linear-motion bearings, are types of bearings that allow smooth and near-frictionless motion in a single axis. Machine tools, robots, actuators, sensors, and other mechanical equipment often require moving components in a straight line in any of the three-dimensional axes...

The materials used for manufacturing the balls in rolling bearings vary widely, but they are primarily chosen to match the materials of the rings. This ensures proper interaction between the cage, outer ring, and inner ring within the system. This consideration is especially crucial when the bearings are subject to heating or cooling in their application. The performance of the ball bearings is critical, and the materials used must ensure reliable operation. Below are the most common materials used for ball bearings and their compatibility with the ring materials:

Ball bearings are specifically engineered for various aerospace applications, including those used in jet engines and helicopters.

Miniature or instrument ball bearings are compact angular contact or deep groove bearings used in applications requiring very small bearings, such as computer disk drives and dental drills.

These bearings are designed similarly to two single-row bearings arranged back-to-back, but they are combined into a single unit to save axial space. They can accommodate both axial and radial loads in either direction, as well as tilting moments.

Angular contact bearings feature one complete ring shoulder, with the other ring either partially or fully removed. This design allows for the use of larger balls, which enhances both load capacity and speed capability. Various cage configurations are available to address specific high-speed needs.

Rolling bearings guide and support rotating machine elements that include axles or wheels, shafts and transfer loads between the components of the machine.

Regular maintenance is essential to ensure their smooth operation and longevity. Lubrication must be applied consistently to keep the bearings functioning effectively. Finding suitable options for these small bearings can be challenging, potentially complicating project completion. To address these difficulties, collaborate with a supplier who offers a comprehensive range of options.

Nonetheless, the varying degrees of load support are fixed as the contact angle remains non-adjustable. Deep groove ball bearings are categorized into the following specific types:

Miniature ball bearings are precisely engineered to reduce friction and extend the lifespan of equipment. Neglecting these small bearings can lead to maintenance issues and reduce flexibility.

This material is used for plastic ball bearings, which feature stainless steel balls that are not hardened. These balls are highly resistant to corrosion, including saltwater and alkalis. Unlike hardened steel balls, which are unsuitable for plastic ball bearings, stainless steel balls are used due to their compatibility with the plastic ring material. The strength of the plastic limits the maximum load capacity of the bearings. Stainless steel balls are also more cost-effective compared to glass balls.

These ball bearings feature a design similar to single row deep groove bearings. They are characterized by deep, uninterrupted raceway grooves that closely fit the balls. This design allows them to support both axial and radial loads in either direction effectively.

Thrust ball bearings are known for their smooth operation, minimal noise, and suitability for high-speed applications. They come in two types: single direction and double direction. The choice between them depends on whether the load is applied in one direction or both.

They are highly resistant to corrosion from water, acids, and salt solutions but should avoid contact with hydrochloric acid, hydrofluoric acid, strong alkaline solutions, and warm sulfuric acid. Additionally, these ceramic balls are self-lubricating and electrically insulating. They are typically white to ivory in color and are manufactured according to ASTM F 2094 Class II/III standards.

Ball bearings used in ball screw applications are often angular contact types with a steep contact angle, such as 60 degrees, and can be configured in duplex, triplex, or quadruplex arrangements. Other designs include bearings with separate radial and thrust rollers in a single assembly and cartridge versions that integrate seals, housings, and bearings.

These bearings not only prevent contamination but also serve as retainers for lubricants. They are constructed from various materials, including ceramic hybrids, stainless steel, cadmium, or plastic, and may be coated with chrome or other materials. They can be re-lubricated, pre-lubricated, or feature solid lubrication. Angular contact bearings are further classified into the following subtypes:

Bearings find specialized applications in diverse fields such as aerospace, automotive, agriculture, ball screw support, medical and dental, precision instruments, pumps, military, sports, high-precision spindles, consumer products, and aircraft or airframe control.

The decrease in force reduces both friction and rolling resistance. Lighter balls enable the bearing to rotate more quickly, consuming less power to sustain its speed. While ceramic balls are harder than the race, ceramic hybrid ball bearings are made with steel rings and ceramic balls. Although ceramic is stronger than steel, it is also more rigid, which can lead to higher stresses on the rings and thus a reduction in load capacity.

Ball bearings decrease surface contact and friction between moving parts by utilizing two separate rings, or "races." The rotating motion of the balls lowers the coefficient of friction compared to flat surfaces that rub directly against each other.

Ball bearings are made up of four main components: two rings (or races), the balls (which are the rolling elements), and the retainer (which separates the balls). Both angular contact ball bearings and radial ball bearings feature an inner and outer ring. These bearings are designed to support radial loads, which are forces applied perpendicular to the axis of rotation.

Ceramic ball bearings use balls made from aluminum oxide, also known as oxide ceramics, which have a polycrystalline structure. These ceramic balls are lightweight and offer excellent properties such as high resistance to corrosion, abrasion, and heat.

As one of the bearing races rotates, the balls turn along with it. The rolling motion of the balls results in a lower coefficient of friction compared to two flat surfaces sliding against each other. Although ball bearings generally have a lower load capacity relative to their size compared to other rolling-element bearings, due to the smaller contact area between the races and the balls, they can accommodate some degree of misalignment between the inner and outer races.

A linear actuator is a means for converting rotational motion into push or pull linear motion, which can be used for lifting, dropping, sliding, or tilting of machines or materials. They provide safe and clean motion control that is efficient and maintenance free...

These bearings feature a large number of balls to provide a relatively high load-carrying capacity and can accommodate axial loads in only one direction. They are usually paired with a second bearing for proper adjustment and consist of non-separable rings.

Each ball bearing has its own specific type of application depending on its material, load-carrying capacity, size, or design. Therefore when selecting a ball bearing, one must take into consideration the type of material used to produce the ball bearing, the size of the ball bearing, the design of the ball bearing, the load-carrying capacity of the ball bearing. The ball bearing must suit its application depending on the mentioned parameters.

Ball bearings are designed to minimize rotational friction while supporting both axial and radial loads. They achieve this by using at least two races to enclose the balls, which transmit the loads. Typically, one race is fixed to the rotating assembly, such as a shaft or hub, while the other race remains stationary.

Ball bearings are generally capable of handling significantly higher dynamic and radial loads compared to static and axial loads. The initial indication of non-elastic deformation is often observed as flattened spots on the balls, which can impede rotation. The lifespan of a bearing is influenced by factors such as operating speeds, load conditions, and environmental conditions. According to industry standards, bearings are expected to remain functional for up to a million rotations, with approximately 90% still being serviceable at this point. This phenomenon is known as bearing fatigue.

The rolling elements rotate at a different speed from the speed of the inner race, but they rotate around the inner race. The separator functions as a barrier that prevents the balls from bumping into each other. The separator is situated between the balls. Thrust bearings support loads that are parallel to the axis of rotation, which are referred to as axial loads. Thrust ball bearings consist of two rings of equal size.

Glass balls are used in metal-free ball bearings, especially when high chemical resistance is required. Soda-lime glass, commonly used in bottles, flat glass, and drinking glasses, is also utilized for ball bearings. It offers good chemical resistance, making it suitable for bearings exposed to mild chemical stress. However, it is not ideal for severe chemical environments. Soda-lime glass is sometimes referred to as "lemon glass" due to its light green hue.

Linear bearings are a type of bearing that "bear" or support the load of the carriage during its single-axis linear movement and provide a low friction sliding surface for the guide rails. In a linear guide, the carriage is the component that travels in a straight line, back and forth, along the length of the guide rail...

Metal ball bearings typically use hardened steel for the balls. Chrome steel, which contains approximately 1% carbon and 1.5% chromium, is a common material for these bearings due to its durability and performance.

8613869596835

8613869596835