Zip Code 32322 Map and Demographics - 32322

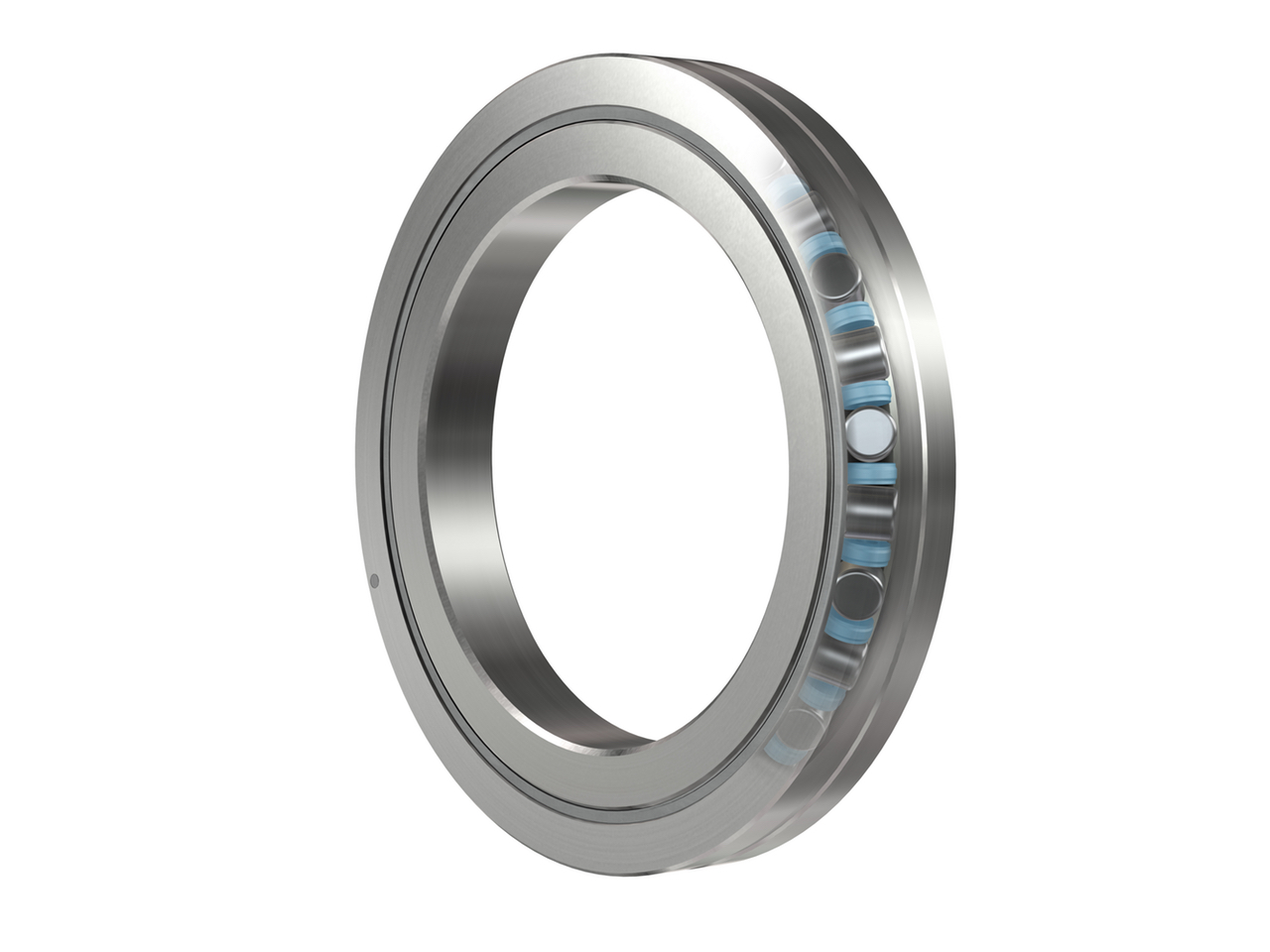

Rollers are arranged by intersecting orthogonally between inner ring and outer ring of the single structure. A separator, which can smoothly rotate rollers, is incorporated between rollers.

Because of the line contact structure, when using rollers for the bearing inner rolling elements, rigidity is greatly improved compared to ball type bearings. For example, rigidity is increased 3 to 4 times while achieving more compact cross-section dimensions compared to a double row Angular Contact Ball Bearing.

We are committed to ensuring that our website is accessible to everyone. If you have any questions or suggestions regarding the accessibility of this site, please contact us.

Crossed Roller Bearings are compact bearings with their rollers alternately crossed at right angles to each other between inner and outer rings. The orthogonal array of rollers allows the bearing to handle complex loads simultaneously from any direction, which makes assembly possible without needing to worry about load direction.

High Rigidity Type Crossed Roller Bearing V has a solid one-piece construction for both inner and outer rings. Therefore, high accuracy and high rigidity are achieved, and mounting errors can be minimized. As separators are incorporated between the cylindrical rollers for smooth rotation, these bearings are suitable for applications where rotation speed is comparatively high. These bearings are widely used in the rotating parts of industrial robots, machine tools, medical equipment, etc., which require compactness, high rigidity and high rotational accuracy. In addition, bearings made of stainless steel and those with inner and outer rings provided with mounting holes are also available on request. Please contact IKO.

The figure is a cross-section of a rotating turntable. The application point distance from the time moment load is applied to the turntable is L, and the allowable moment load of the bearing is proportional to application point distance L. If increasing application point distance L to increase the moment rigidity of the turntable, two Angular Contact Ball Bearings are required. Because of the need for distance between the bearings, the equipment size increases as well. However, even a single Crossed Roller Bearing can increase application point distance L, keeping equipment compact and improving moment rigidity.

The orthogonal array of rollers reduces the cross sectional area of rear-mounted 45° contact angle roller bearings or single row ball bearings by half. This compact design allows you to more effectively utilize space in your application.

All ISO publications and materials are protected by copyright and are subject to the user’s acceptance of ISO’s conditions of copyright. Any use, including reproduction requires our written permission. All copyright requests should be addressed to copyright@iso.org.

8613869596835

8613869596835