ZIP Code 61822, Champaign, IL - 61822

Joseph has written about engineering and cars for Autozilla, Komaspec, and several engineering manufacturers. When he's not writing or tinkering with one of his five cars, Joseph dreams of owning an Alfa Romeo 33 Stradale.

How to tell whichwheel bearingis bad while driving

Most wheel bearing components are heat-treated to harden the metal. But, the heat-treating can also penetrate far into the metal. Once the bearing has worn through this layer, rapid and catastrophic wear occurs to the softer metal below. This type of fatigue failure is called “spalling.” This kind of damage causes the metal to come off in flakes.

As a rule, end-play should be about 0.001 to 0.005 inches. There should be no play on most FWD cars. Up to 0.010 inch of play in the front wheel bearings may be acceptable on RWD cars and trucks with adjustable bearings. On FWD cars with adjustable tapered roller rear wheel bearings, the bearing adjustment procedure is usually the same as with RWD vehicles (zero pre-load), but some do require a slight pre-load. Ford, for example, says the rear wheel bearings on older Taurus models should be lightly pre-loaded to 24 to 28 in-lbs (2 ft-lbs).

Average life ofwheelbearings

When a bearing completely fails, the hub nut can no longer stop the outer bearing race, hub and wheel from sliding off the axle. In short, the wheel can literally fall off the car.

Split the cost of car repairs into easy monthly repayments with completely interest-free car repair finance. Find a Bumper partner near you.

Seals are critical components for the longevity of a wheel bearing. If contaminants from the outside find their way inside, this could cause a wear pattern called busing. One must never re-use seals. Used seals can leak and contaminate brake linings or cause premature wheel bearing failure.

If you can hear a new noise, particularly a droning that increases in volume and frequency with speed, there's a good chance you have a failing wheel bearing.

This can start to happen because the wheel bearing ensures the wheels are rotating in a single plane and not moving side to side when the bearing wears out.

When doing an MOT, the tester will lift your car and firmly pull on the wheels in various directions. Excess movement in the wheel, when pulled from the top or bottom, is usually a symptom of a failing wheel bearing.

As these contaminants circulate through the grease and between the races and bearings, the components wear and possibly change their metallurgy.

Wheel bearings are considered a standard wear and tear item on a car. Depending on the number of miles you drive and how long you keep a car, you should expect to have to replace them at some point.

Typically it is cheaper to replace a bearing on a non-driven axle, as there are fewer components to remove, with most cars being front-wheel drive (except for many BMW and Mercedes cars) this means the rear bearings are cheaper.

Frontwheel bearingnoise symptoms

However, determining which one is at fault takes a little more investigation. See below for instructions on how to examine wheel bearing problems.

Another determining factor is when the noise is present; if, when braking, the noise gets louder, this usually means that one of the front bearings is worn out. This is because the action of the weight of the car shifts more to the front wheels when decelerating.

A good service adviser will interview the customer to find out what kinds of roads the vehicle predominately drives on. Also, the adviser may ask what types of loads the vehicle carries on a regular basis. If a driver overloads the vehicle, bearing damage could be inevitable.

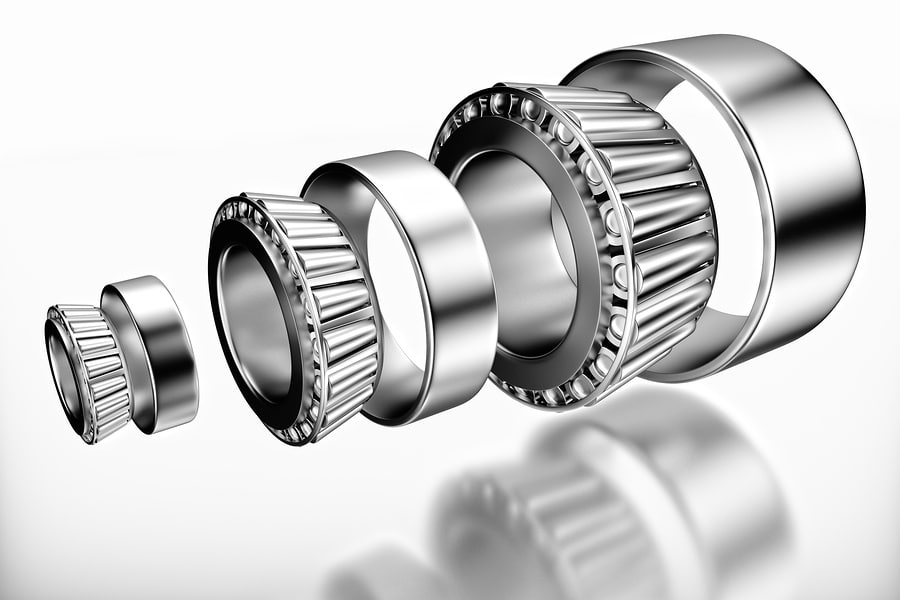

Bearings are absolutely everywhere in machinery and vehicles. Anything with moving parts will always have a bearing of some kind. Car wheels require strong and precise bearings to cope with the large forces of bumps and turns.

How long willa wheel bearinglast after it starts making noise

However, life expectancy depends on how often you drive and the condition of the roads you drive on. This may mean wheel bearings need replacing sooner or later, but they won’t need replacing regularly.

If a wheel bearing overheats, the hot lubricant breaks down and can cause scoring and even etching of the bearing surface. Also, water and other corrosive elements can create this condition, which lead to spalling down the road. Burned or oxidized lubricant may leave a dark coating on bearing surfaces. Remember that with tapered roller bearings, excessive pre-load can mimic this same damage pattern. If a wheel bearing gets really hot, cages and seals could be deformed and lead to bearing lock-up. For these reasons, a vehicle owner should seek a professional facility to perform such repairs. Wheel bearing replacement requires experience to both remove the old bearing without damaging other components and install the replacement part in a manner that will provide optimal and lasting performance from the new part. A wheel bearing is not a component that should be purchased with cost being the primary buying decision variable.

Badwheel bearingsymptoms

The inside of a bearing can be a hot place. When a bearing is cooling off, the contracting metal, air, and lubricant, can create a vacuum that is hopefully held by the seals. If the seals are worn and can’t hold the vacuum, the bearing or sealed hub unit will suck in outside air, debris, and water. In parts of the country that use salt on the roads, it is almost as bad as ocean water on wheel bearings.

Like many components on a car, wheel bearings almost always give plenty of warning, audible and otherwise, that they’re starting to fail. Also, like other parts, the consequences of allowing one to fail can be severe.

Wheel bearing replacement is a common issue, so the parts are relatively cheap, and any competent garage well understands the process. Typical parts prices range from £30 to £250, but then you have to include the labour costs as well.

As bearings wear, they create more noise. The noise from a wheel bearing will be a constant droning or scraping noise and is the best way to tell if there is a problem.

Also, the poor quality steel may have inclusions of hard or soft metal that can cause a premature failure. In summary, an inexpensive wheel bearing may look the same as a high-quality, more expensive wheel bearing, but it is what you can’t see that makes a difference when having to replace the new part much sooner than the original component lasted.

The traditional construction of a bearing is two rings, called races, and small balls. When assembled the balls transmit the load between the inner and outer races whilst allowing rotation and retaining their position laterally (side to side).

Once a bearing is worn, the wear rate is accelerated by seals that no longer keep out contaminants, and increased heat may breakdown and eventually expel the lubricants. This is a slippery slope that could quickly lead to catastrophic failure.

When a wheel bearing wears out, it is usually a case of inadequate lubrication, faulty installation, or improper adjustment. For the repair to be successful, an experienced mechanic must first determine why the previous bearing failed. For sealed hub units, examining the internal bearings and races is impossible.

Be careful when touching any part of the wheels as they can become very hot depending on the severity of the bearing issue and if you have been braking hard. But if one wheel is slightly warmer, this could indicate a bearing problem.

Split the cost of car repairs into monthly payments with Bumper. Apply online before your visit and choose from lots of garages already on the Bumper network.

Bearings are precision products that require complex manufacturing processes. Inferior bearings that use low-quality steel an have poor heat-treating can wear and fail prematurely.

If you have questions about our Towson wheel bearing services or need assistance with oxygen sensor repair or any other automotive service, don’t hesitate to reach out to Hollenshade’s. Our knowledgeable team is always ready to assist you. Feel free to give us a call at 410-828-5750 to speak with a friendly and experienced team member today. We’re committed to providing exceptional automotive services and ensuring your vehicle’s optimal performance.

Not sure what to look at, or hear for when they might need replacing? Worried about the cost of wheel bearings? Or simply want to understand a bit more about how wheel bearings work?

Wheel bearingreplacement cost

If it's too difficult to tell, especially with how well sound-insulated modern cars are, a passenger can try listening to the noise from the front and then rear seats.

Because a bearing's job is to reduce friction, when they’re not working as they should, more friction and therefore heat is generated. This can often be felt on the wheel after a long drive.

Catastrophicwheel bearingfailure

So, if you’re wondering if wheel bearings are expensive, the price ultimately comes down to which specific parts your car needs.

Not only can this cause a wayward steering feel, but it can also wear out your front tyres faster. If your car feels like this when steering and shows other signs of a worn bearing, get it checked as soon as possible.

While a mechanic will be best placed to properly diagnose your wheel bearing issues, there are some symptoms to look out for. Here are four signs drivers need to know:

You can estimate your wheel bearing cost depending on the type you buy. Here’s a quick overview of the different price brackets:

Wheel bearings are a small yet mighty part of your car vital to movement and safety. If they’re not functioning properly, you must replace them immediately.

The most common failure pattern for wheel bearings is for those on the passenger side of the vehicle to fail first. The passenger side bearings are exposed to the most standing water in the gutter. If the bearing on the driver side of the vehicle fail first, take an extremely close look at the passenger side bearings, as failure may not be far behind.

What happens when a wheel bearing failswhile

A driver may notice noise coming from the vicinity of the wheel, maybe some steering wander or looseness in the steering, and abnormal tread wear on the front tire. The noise may change when tuning, become louder, or even disappear at certain speeds. This noise should not be confused with the clicks and pops produced by a worn outer CV joint on a FWD car. A bad outer CV joint usually only makes noise when turning, not when driving straight ahead.

Over-tightening adjustable tapered roller wheel bearings is a common error of amateur/un-trained mechanics that can lead to premature failure. Tapered roller bearings on the font of RWD vehicles are never pre-loaded. They’re snug up with no more than 15 to 20 ft-lbs of torque while rotating the wheel to make sure the bearings are seated. Then, the adjustment nut is loosened 1/6 to 1/4 turn, and locked in place with a new cotter pin.

Now you’ve figured out roughly where the offending bearing is, it should be pretty easy to determine which side is at fault:

The wheel hub - the part that the wheel bolts to - is held in place by the hub-nut, which prevents the wheel and hub from coming off the axle.

Obviously, this is an extremely dangerous situation. It can cause a complete loss of control and a high chance of injury.

If you hear an unfamiliar noise when drifting to the left, there may be a problem with your right wheel bearing. If the noise occurs when you drift right, the left wheel bearing may be faulty.

Whilst wheel bearings can take a while to get to the replacement point, it’s still important to have the bearing checked as soon as you notice a new noise or feel any symptoms. Hopefully, this guide has introduced you to wheel bearing replacement costs and answered some questions you may have had. When in doubt, consult a professional mechanic or work with a garage to achieve a safe solution.

Because they support the road wheels, wheel bearing noise depends on speed. If you notice a noise that stays the same volume and pitch when doing 30mph or 70mph, it’s probably not a wheel bearing.

Joseph has been writing about cars for over seven years and writing for Bumper for over two, blending his passion for automobiles with a talent for storytelling.

According to automotive aggregate data services, the replacement market for wheel bearings and hub assemblies is estimated to be roughly $120M annually. Larger suppliers include Timken, SKF, BCA, and Centric. However, many wheel bearings that may need to be replaced are not because they are overlooked when other wheel services and repairs are being performed on the vehicle.

Modern wheel bearings are often made into modular units that bolt on and off the car for easy maintenance. Older cars, and some new ones, require powerful hydraulic presses to force out the old bearings and ‘press in’ the new ones.

8613869596835

8613869596835