碳纤维真的比铝合金好吗?关于碳纤维和铝合金你需要知道 ... - 纵向拉力强度 碳纤维

THKlinearGuide catalogue PDF

Dust Prevention Side-seals are provided as a standard. To improve the dust prevention characteristics, under-seals, double-seals, scrapers, bellows and special rail mounting caps are also available.

Low Friction Because a 4-row/2-point contact design is used, low friction and stable motion characteristics are achieved even under a preloaded conditions.

By marrying compact design with high-quality materials and precision manufacturing, we can provide high load capabilities for use in small equipment. We’ve included advanced features such as error absorption, dust prevention and integrated lubrication to increase your efficiency and keep your machines running — even in demanding environments.

A 45° contact angle (equal top to bottom and side to side) distributes your load evenly and allows for maximum design flexibility and motion.

Thanks to our two-point contact across four rows, our bearings provide low friction and motion that is stable and smooth, even at high speeds.

LinearGuide Block

Large ball elements and tight raceway groove machining provide the greatest contact area possible, which results in higher load ratings, even in single rail applications.

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

• Integrate fiber-sheet lubrication unit into the block to keep your raceway grooves properly lubricated and extend the service life significantly.

NB linear guides offer easy and flexible integration into all of your equipment and machinery. To facilitate your design phase, you can download 2D and 3D CAD files and incorporate them into your new machine designs or older machine upgrades. You’ll find an NB Slide Guide SGL system is the perfect solution to your most demanding linear motion problems. Download the CAD files today or contact us for more information.

Our self-aligning ball elements absorb dimensional error during mounting. This means faster installation and greater confidence at startup.

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Design linear rail groovepdf

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

HIWINLinearGuideways catalogue PDF

Anti-corrosion Specification The rail and block assembly can be treated with low temperature black chrome treatment to increase the corrosion resistance. This treatment is standardized with the symbol “LB”. Stainless steel SGLS type is suitable for use in clean room application.

At NB, you’ll find linear guide rails and linear guide bearings that cover a wide range of general machinery and high-precision equipment across all industries. Our NB Slide Guide SGL system uses a profile-style rail that takes advantage of the recirculating ball design. It will provide reliable linear movement and positioning for all of your equipment.

Linearrails

Industry demands more precise, smaller, lighter and longer-life linear guides and linear bearings. We responded by adding more features and advantages to our NB Slide Guide SGL system. By incorporating our system into your machinery, you benefit from:

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

LinearGuiderailcatalogue

• Increase corrosion resistance with stainless-steel and block or carbon steel with low temperature black chrome treatment (LB).

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

Your efficiency depends on your equipment being operational and reliable at all times. NB incorporates materials and features that provide longer service life and degradation in demanding environments. Choose NB Slide Guide SGL linear guide rails for all of your applications. You’ll appreciate that we:

Our linear guideways and block assemblies are suitable for general machinery uses as well as high-precision/tight tolerance measurement and optical equipment. Thanks to our high load carrying capacity, it is often possible to design your system to use a single linear guide rail, reducing cost and space requirements.

Linear railtypes

Fiber Sheet Extends Lubricant Replenishment Intervals A lubricant-containing Fiber Sheet incorporated in the block supplies appropriate amount of lubricant to the raceway grooves at appropriate intervals, which can significantly extend the lubricant replenishment interval.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

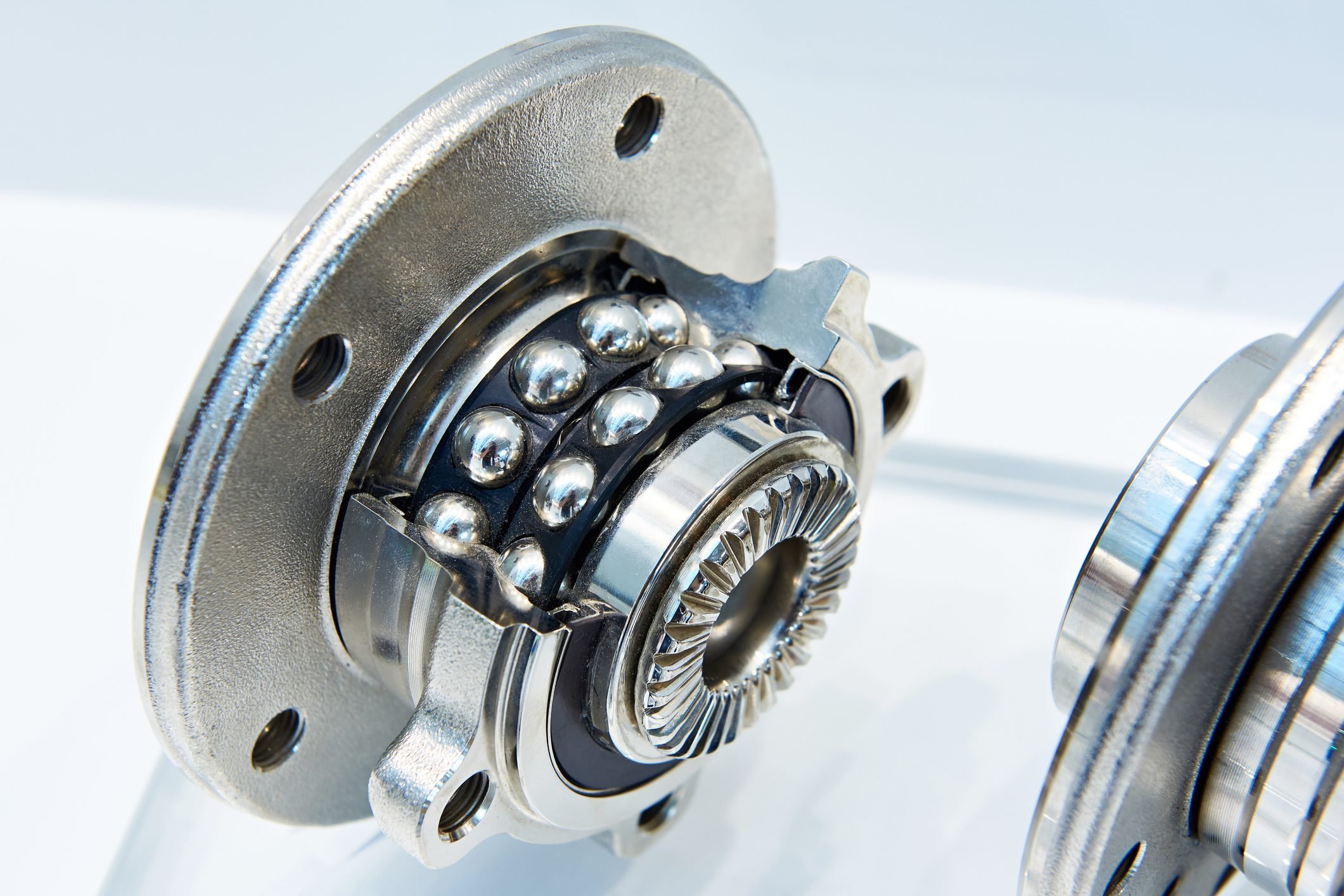

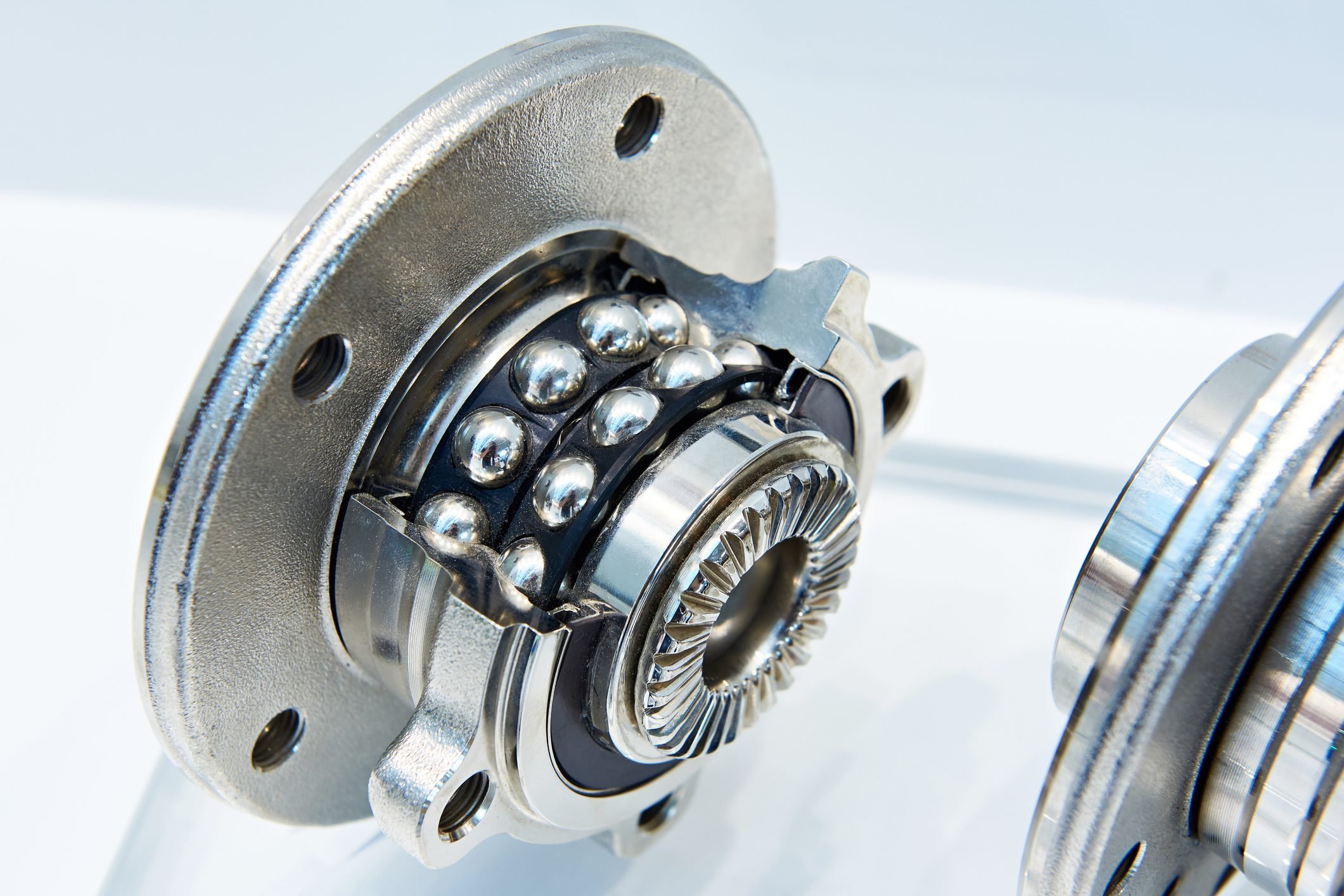

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

LinearGuideRail

The NB SLIDE GUIDE SGL type is a profile linear guide rail system utilizing the recirculating motion of ball elements along four rows of raceway grooves. It can be used in various applications due to its compactness and high load capacity.

High Load Capacity and Long Life The use of relatively large ball elements and raceway grooves machined to a radius close to that of the ball elements increases the contact area resulting in a high load capacity and a long travel life.

The NB SLIDE GUIDE SGL type consists of a rail with 4 rows of precisely machined raceway grooves and a block assembly. The block assembly consists of the main body, ball elements, retainers, and return caps.

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

Omni-Directional Load Capacity The ball elements are positioned at 45° contact angle so that the load capacity is equal in four directions (above, below, right and left). Absorption of Mounting Dimensional Error Because the ball elements are positioned to increase their self-aligning characteristics, the dimensional error caused during installation is absorbed.

8613869596835

8613869596835