Heavy Duty Sealed Tapered Roller Bearings: Ultimate Guide for Industrial Buyers

In global trade, heavy duty sealed tapered roller bearings are critical components for machinery operating under extreme loads and harsh conditions. These bearings combine radial and thrust capacity while preventing contaminant ingress - a common pain point for buyers struggling with premature bearing failures in mining, construction, or agricultural equipment.

Technical Specifications and International Standards

Heavy duty sealed tapered roller bearings feature:

- Load capacity: 30-40% higher than standard bearings (ABMA Scale 9)

- Sealing: Triple-lip contact seals with HNBR material

- Operating range: -40°C to 150°C continuous duty

Compliant with ISO 355 (2014) and ANSI/ABMA 12.1 standards for dimensional interchangeability.

Competitive Advantages vs Alternative Solutions

| Feature | Sealed Tapered | Open Tapered | Cylindrical |

|---|---|---|---|

| Contaminant Protection | ✔️ | ❌ | ❌ |

| Combined Load Capacity | ✔️ | ✔️ | ❌ |

| Lubrication Retention | ✔️ | ❌ | ❌ |

Cost-Saving Benefits for Industrial Operations

- Maintenance reduction: 62% longer regreasing intervals (McKinsey 2023 report)

- Downtime prevention: 3.2x mean time between failures vs unsealed versions

- Inventory simplification: Single bearing replaces separate radial/thrust units

Global Market Demand Analysis

The heavy duty bearing market will grow at 5.8% CAGR through 2030 (Statista), with particular demand from:

- South American mining sector ( 12% YOY)

- Middle East oilfield equipment replacements

- Asian infrastructure projects

Supplier Qualification Checklist

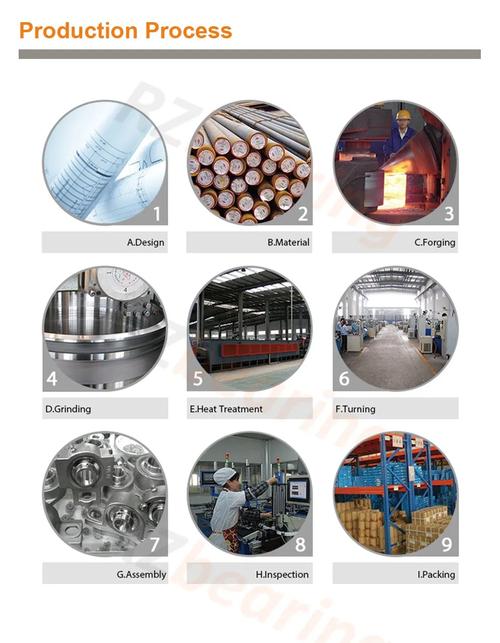

Verify manufacturers have:

- ISO 9001:2015 certification

- Material traceability documentation

- Third-party load testing reports

- Minimum 18-month warranty

FAQ Section

How to negotiate bulk pricing effectively?

Request tiered pricing for 500 /1000 units and consider annual contracts.

What are typical MOQs for custom sizes?

Standard MOQ is 50 pieces; custom designs may require 200 units.

Can you provide special seal materials?

Yes, we offer FKM and PTFE seals for chemical/food applications.

Do you handle export documentation?

Full INCOTERMS 2020 support including CFR and DDP shipments.

How is quality verified before shipment?

100% dimensional checks batch testing per ISO 15243:2017.

What payment methods do you accept?

LC at sight, 30% TT deposit, or credit terms for repeat customers.

Ready to upgrade your equipment reliability? Download our bearing selection guide or schedule a technical consultation today.

13869596835

13869596835