Industrial Needle Roller Bearing Suppliers: Your Ultimate Guide to Reliable Sourcing and Performance

## Industrial Needle Roller Bearing Suppliers: Your Ultimate Guide to Reliable Sourcing and Performance

### Introduction

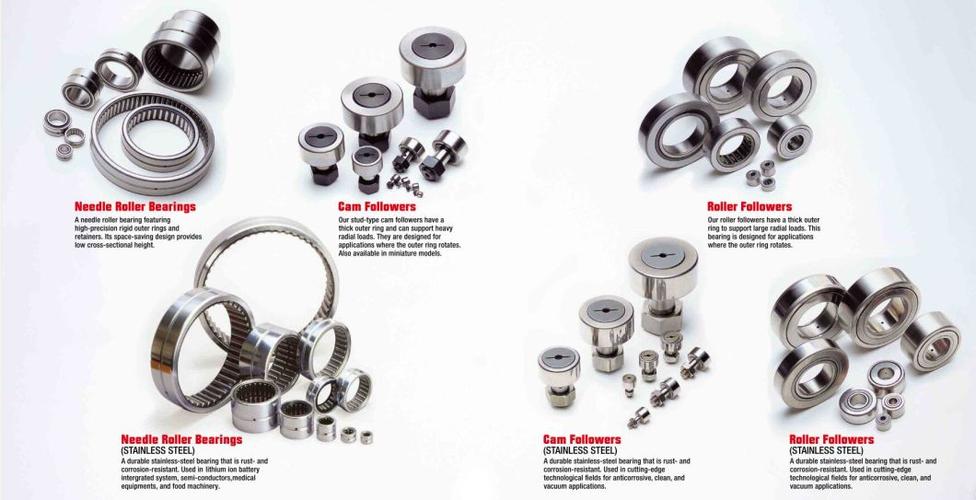

Industrial needle roller bearings represent **precision-engineered solutions** for applications requiring high load capacity within limited space. These cylindrical roller bearings with small diameter rollers (3-10mm) have become indispensable in automotive transmissions, aerospace actuators, and heavy machinery. The global needle roller bearing market is projected to reach $3.8 billion by 2025 (Grand View Research), driven by increasing automation and electric vehicle production.

Modern manufacturers face critical challenges: 83% of engineering failures originate from improper bearing selection (ASME Journal). This underscores the importance of partnering with **qualified industrial needle roller bearing suppliers** who understand technical specifications and operational environments. How can businesses navigate this complex landscape to secure components that enhance machinery lifespan and performance?

---

### What Are Industrial Needle Roller Bearings?

Needle roller bearings utilize cylindrical rollers with length-to-diameter ratios exceeding 4:1, enabling:

- 30-50% space reduction compared to standard roller bearings

- Dynamic load capacities up to 450,000 N

- Operational temperatures ranging from -40°C to 150°C

Common industrial applications include:

- Gearbox assemblies in wind turbines

- Robotic joint mechanisms

- Medical imaging equipment rotation systems

13869596835

13869596835