Comprehensive Guide to Ball Bearings Types: Selection, Applications, and Maintenance

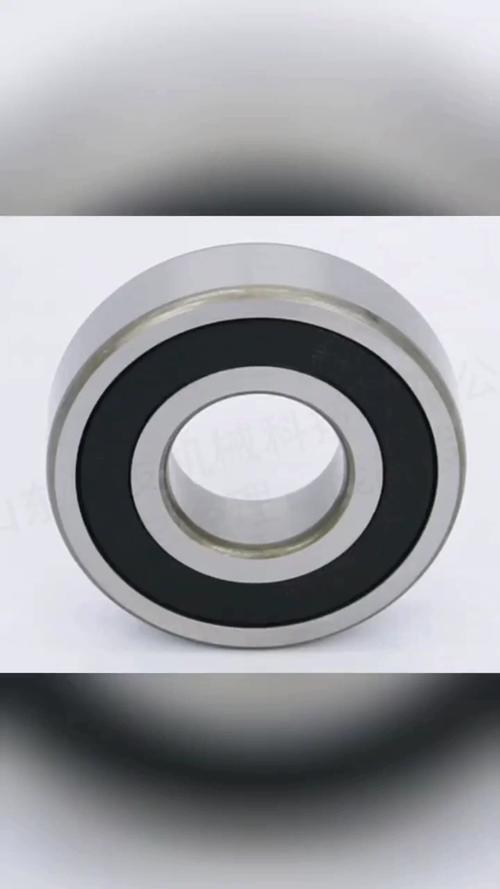

Ball bearings are precision-engineered components that reduce rotational friction between moving parts in machinery. These mechanical assemblies come in various configurations to handle radial/axial loads, speeds, and environmental conditions. Understanding different ball bearings types helps engineers select optimal solutions for industrial equipment, automotive systems, and precision instruments.

1. types of ball bearings2. ball bearing applications

3. ball bearing materials

4. how to choose ball bearings

5. ball bearing maintenance

1. Types of Ball Bearings

Deep groove ball bearings feature uninterrupted raceways... Angular contact bearings manage combined loads through calculated contact angles... Thrust ball bearings specialize in axial load applications... Self-aligning bearings compensate for shaft misalignment... Miniature bearings enable precision in medical devices... Each type serves distinct mechanical requirements across industries.

Deep groove ball bearings feature uninterrupted raceways... Angular contact bearings manage combined loads through calculated contact angles... Thrust ball bearings specialize in axial load applications... Self-aligning bearings compensate for shaft misalignment... Miniature bearings enable precision in medical devices... Each type serves distinct mechanical requirements across industries.

2. Ball Bearing Applications

Automotive transmissions rely on tapered roller bearings... Aerospace actuators use ceramic hybrid bearings... Industrial pumps employ stainless steel bearings... Electric motors incorporate shielded bearings... Robotics joints demand precision angular contact bearings... Material handling systems utilize reinforced cage designs... Proper application matching ensures optimal performance.

3. Ball Bearing Materials

Chrome steel (GCr15) remains standard for general purposes... Stainless steel (440C) resists corrosion... Ceramic hybrids reduce electrical arcing... Polymer cages dampen vibration... High-temperature alloys withstand 300°C environments... Surface treatments like black oxide prevent corrosion... Material selection impacts load capacity and service life.

4. How to Choose Ball Bearings

Calculate radial/axial load requirements... Determine operational RPM range... Assess environmental factors... Consider lubrication methods... Match internal clearance to thermal expansion... Verify dimensional tolerances... Evaluate sealing requirements... Compare static/dynamic load ratings... Consult bearing life calculations.

5. Ball Bearing Maintenance

Implement proper lubrication intervals... Monitor vibration patterns... Check temperature thresholds... Inspect seal integrity... Clean contamination points... Measure axial play... Record service hours... Utilize condition monitoring tools... Follow manufacturer guidelines... Store bearings properly.

Understanding ball bearings types requires analyzing multiple engineering factors - from load dynamics to environmental challenges. Whether selecting materials for chemical resistance or determining maintenance schedules for heavy machinery, each aspect impacts operational efficiency. This guide systematically addresses critical considerations for optimal bearing performance.

This comprehensive overview equips professionals with essential knowledge about ball bearing types and their practical implementations. From material science to maintenance protocols, proper bearing management significantly enhances equipment reliability. Implement these insights to optimize mechanical systems across industries.

13869596835

13869596835