ABEC Rated Ball Bearings: A Comprehensive Guide to Grades, Selection, and Applications

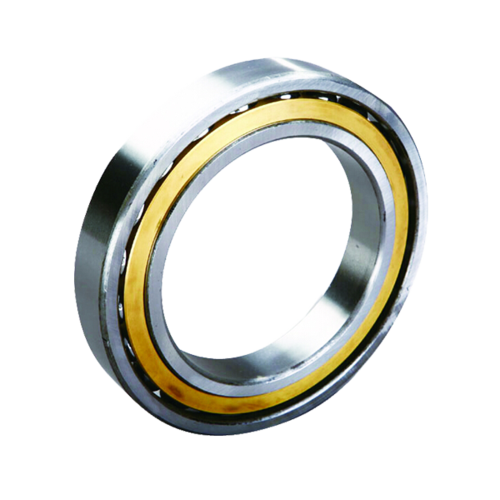

ABEC rated ball bearings are precision-engineered components designed to meet specific tolerance and performance standards set by the Annular Bearing Engineers Committee (ABEC). These ratings (ABEC 1, 3, 5, 7, 9) classify bearings based on rotational accuracy, noise levels, and speed capabilities, making them critical for applications requiring high reliability in aerospace, robotics, and automotive industries.

1. ABEC ratings explained2. ABEC 7 vs ABEC 5 bearings

3. How to choose ABEC rated bearings

4. ABEC ratings and bearing precision

5. Applications of ABEC rated bearings

1. ABEC ratings explained

ABEC ratings measure dimensional accuracy and rotational precision using five classes. ABEC 1 offers basic tolerances (±0.0075mm) for low-speed applications like skateboards. ABEC 3 balances cost and performance for electric motors. ABEC 5 (±0.004mm) suits CNC machines requiring moderate speeds. ABEC 7 (±0.0025mm) delivers ultra-smooth operation for dental drills and robotics. ABEC 9 (±0.0012mm) serves specialized aerospace systems. Higher grades reduce friction by 15-30% but increase manufacturing costs by 40-60%.

ABEC ratings measure dimensional accuracy and rotational precision using five classes. ABEC 1 offers basic tolerances (±0.0075mm) for low-speed applications like skateboards. ABEC 3 balances cost and performance for electric motors. ABEC 5 (±0.004mm) suits CNC machines requiring moderate speeds. ABEC 7 (±0.0025mm) delivers ultra-smooth operation for dental drills and robotics. ABEC 9 (±0.0012mm) serves specialized aerospace systems. Higher grades reduce friction by 15-30% but increase manufacturing costs by 40-60%.

2. ABEC 7 vs ABEC 5 bearings

ABEC 7 bearings outperform ABEC 5 in high-RPM scenarios (20,000 RPM) with 50% less vibration. They maintain tighter radial tolerances (0.0025mm vs 0.004mm), reducing heat generation by 18% in turbochargers. However, ABEC 5 provides better cost-efficiency for applications below 15,000 RPM like industrial pumps. ABEC 7's polished raceways extend service life by 30% in MRI machines but require 25% more maintenance precision.

3. How to choose ABEC rated bearings

Select bearings based on operational RPM, load type, and environmental factors. For <15,000 RPM axial loads, ABEC 3 suffices. Radial loads above 20,000 RPM demand ABEC 7. Corrosive environments require stainless steel ABEC 5 bearings with IP67 seals. Calculate required lifespan: ABEC 7 lasts 8,000 hours vs ABEC 5's 5,000 hours in continuous operation. Always cross-reference ISO 492 standards for international compliance.

4. ABEC ratings and bearing precision

ABEC classifications directly impact rotational accuracy. ABEC 9 achieves 0.0001° angular contact deviation, crucial for satellite gyroscopes. Precision affects torque: ABEC 7 reduces startup torque by 22% compared to ABEC 3 in servo motors. Surface finish (Ra 0.05µm for ABEC 7 vs 0.1µm for ABEC 5) minimizes lubricant degradation. Remember that precision tolerances require temperature-controlled assembly environments (±1°C variation).

5. Applications of ABEC rated bearings

ABEC 7-9 bearings dominate medical devices (surgical robots require 0.003mm runout accuracy). ABEC 5 is standard for EV traction motors. Aerospace uses hybrid ABEC 7 bearings with ceramic balls for 180°C operations. Industrial drones utilize ABEC 5 for cost-effective 15,000 RPM motor speeds. High-end gaming PCs employ ABEC 3 fan bearings for silent operation under 25dBA noise thresholds.

Understanding ABEC ratings unlocks optimal bearing performance across industries. Whether comparing ABEC 7 precision advantages, selecting bearings for harsh environments, or implementing medical-grade solutions, this guide provides actionable insights. Discover how proper ABEC class selection can reduce energy consumption by up to 12% in your applications while extending equipment lifespan.

This comprehensive analysis demonstrates how ABEC ratings directly influence mechanical efficiency and operational costs. From precision robotics to high-speed manufacturing systems, selecting the appropriate bearing class ensures optimal performance. Implement these guidelines to enhance equipment reliability while meeting industry-specific certification requirements.

13869596835

13869596835