Top 5 Industrial Bearings for Sale: A Comprehensive Buyer’s Guide 2023

Industrial bearings are critical components in machinery across manufacturing, automotive, and construction industries. This guide explores essential information about purchasing high-quality industrial bearings, including key suppliers, technical specifications, and market trends for 2023.

Table of Contents

1. industrial bearings manufacturers2. high precision bearings suppliers

3. buy industrial bearings online

4. industrial ball bearings catalog

5. heavy duty roller bearings price

1. Industrial Bearings Manufacturers

Selecting reliable industrial bearings manufacturers requires evaluating ISO certifications, production capabilities, and industry experience. Leading global manufacturers like SKF and NSK maintain strict quality control standards for radial ball bearings, tapered roller bearings, and slewing ring bearings. Custom bearing solutions for extreme temperatures or corrosive environments demand manufacturers with specialized engineering teams and material testing facilities.

2. High Precision Bearings Suppliers

High precision bearings suppliers must provide ABEC-7 or higher grade components for aerospace and medical equipment applications. Critical factors include micron-level tolerances, advanced lubrication systems, and vibration reduction technologies. Reputable suppliers offer comprehensive technical documentation and load capacity charts to ensure compatibility with high-speed CNC machines or robotics systems.

3. Buy Industrial Bearings Online

When buying industrial bearings online, verify platform credibility through SSL certification and customer reviews. Trusted e-commerce portals provide detailed product filters for bore size (10mm-500mm), sealing types (RS/ZZ), and cage materials (steel/nylon). Bulk purchasing options with volume discounts and OEM packaging services are essential considerations for procurement managers sourcing angular contact bearings or spherical roller bearings.

4. Industrial Ball Bearings Catalog

A comprehensive industrial ball bearings catalog should categorize products by series (6000, 6200, 6300), dynamic load ratings, and temperature ranges. Digital catalogs with 3D CAD models enable engineers to verify dimensions and mounting requirements. Leading distributors update catalogs quarterly with new stainless steel bearings, ceramic hybrid bearings, and sensor-equipped smart bearing solutions.

5. Heavy Duty Roller Bearings Price

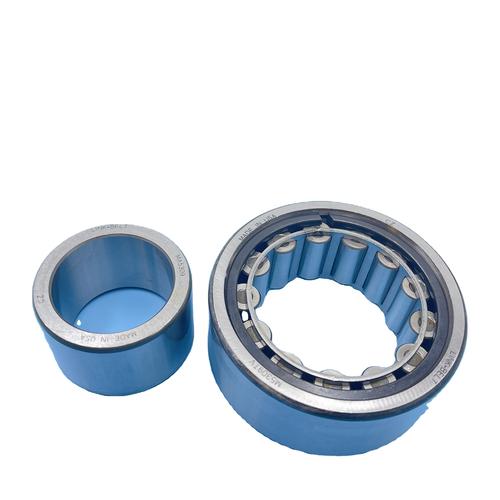

Heavy duty roller bearings price varies based on material grade (GCr15 steel vs chromium carbide), precision class (P0-P6), and anti-corrosion treatments. Current market trends show 5-8% price increases for large-bore cylindrical roller bearings used in wind turbines and mining equipment. Request detailed quotations comparing FOB prices, MOQs, and HS codes for customs clearance efficiency.

Understanding these five critical aspects of industrial bearings ensures informed purchasing decisions. Whether sourcing precision components for pharmaceutical machinery or rugged bearings for construction equipment, this guide provides actionable insights into technical specifications, supplier verification, and cost optimization strategies.

This comprehensive guide covers essential considerations for purchasing industrial bearings, from manufacturer selection criteria to online procurement best practices. By understanding precision requirements, catalog navigation, and market pricing trends, buyers can secure optimal bearing solutions that enhance equipment performance and reduce maintenance costs.

13869596835

13869596835