Precision Bearings for Sale: A Comprehensive Guide to Types, Applications, and Buying Tips

Precision bearings are critical components in machinery requiring high accuracy, minimal friction, and long-term durability. Used in aerospace, automotive, robotics, and medical equipment, these bearings ensure smooth operation under extreme conditions. When sourcing precision bearings for sale, factors like material quality, tolerance levels, and certifications must be prioritized to meet industry standards.

Table of Contents

1. high precision ball bearings2. precision roller bearings

3. industrial precision bearings

4. precision bearings manufacturers

5. buy precision bearings online

1. High Precision Ball Bearings

High precision ball bearings are engineered to minimize rotational friction while supporting radial and axial loads. These bearings feature ultra-smooth surfaces and tight tolerances, often made from chrome steel or ceramic materials. They are ideal for applications like CNC machines, dental drills, and optical instruments where micron-level accuracy is essential. When purchasing, verify ISO 492 Class 2 or ABEC 7/9 ratings to ensure compliance with international standards. Leading manufacturers employ advanced heat treatment and grinding techniques to achieve roundness deviations below 0.0001 inches. Lubrication selection is crucial—synthetic oils or grease must match operational temperatures and speed requirements.

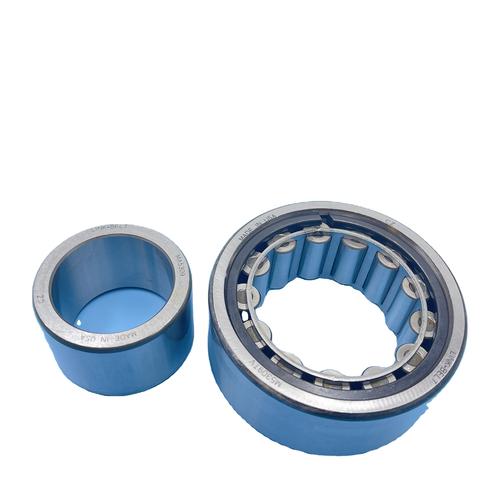

2. Precision Roller Bearings

Precision roller bearings excel in handling heavy radial loads with high rotational speeds. Cylindrical, tapered, and spherical variants cater to different mechanical configurations. In wind turbines and heavy machinery, these bearings reduce vibration through optimized roller alignment and premium alloy construction. Look for designs with integrated seals to prevent contamination in harsh environments. Recent advancements include hybrid bearings combining steel races with ceramic rollers, offering 30% higher speed capacity and reduced thermal expansion. Always cross-reference dynamic load ratings (C/P values) with application demands during selection.

3. Industrial Precision Bearings

Industrial precision bearings are the backbone of manufacturing automation and robotics systems. These bearings undergo rigorous testing for noise levels, vibration (ANSI/ABMA Std 12.1), and lifespan under continuous operation. Stainless steel variants resist corrosion in food processing or chemical industries, while vacuum-compatible models suit semiconductor production. Smart bearings with embedded sensors are emerging trends, providing real-time data on temperature and load distribution for predictive maintenance. Partner with suppliers offering CAD models and technical support to streamline integration into custom machinery designs.

4. Precision Bearings Manufacturers

Selecting reputable precision bearings manufacturers involves evaluating their ISO 9001 certification, R&D capabilities, and industry-specific expertise. Top-tier companies like SKF, NSK, and Timken invest in nanotechnology surface treatments and 3D measurement systems for quality assurance. Request material test reports (MTRs) and failure mode analysis documentation. Customization options—such as modified cage designs or specialty coatings—should be available for unique applications. Consider regional logistics hubs; European manufacturers often lead in aerospace-grade bearings, while Asian suppliers provide cost-effective solutions for consumer electronics.

5. Buy Precision Bearings Online

To buy precision bearings online safely, prioritize platforms with detailed product specifications, CAD downloads, and authenticated supplier profiles. E-commerce portals like BearingsDirect or Misumi offer parametric search filters for bore size, load direction, and sealing types. Verify return policies for mismatched specifications and check for HTTPS encryption on payment pages. Cross-reference prices across multiple sellers—unusually low costs may indicate counterfeit products. Subscribe to B2B marketplaces like Alibaba Gold Supplier for bulk procurement discounts and third-party inspection services.

Understanding these five critical aspects—from bearing types to trusted purchasing channels—empowers engineers and procurement teams to make informed decisions. Whether upgrading existing machinery or designing cutting-edge systems, the right precision bearings directly impact operational efficiency and maintenance costs. Dive deeper into each section to explore technical specifications, compare leading brands, and identify cost-saving strategies without compromising quality.

Conclusion

Selecting precision bearings requires balancing technical requirements, supplier reliability, and budget constraints. This guide has outlined key considerations for identifying optimal solutions across industries. By leveraging manufacturer certifications, material innovations, and secure online purchasing platforms, businesses can enhance equipment performance and longevity. Always consult engineering datasheets and conduct prototype testing before full-scale implementation.

13869596835

13869596835