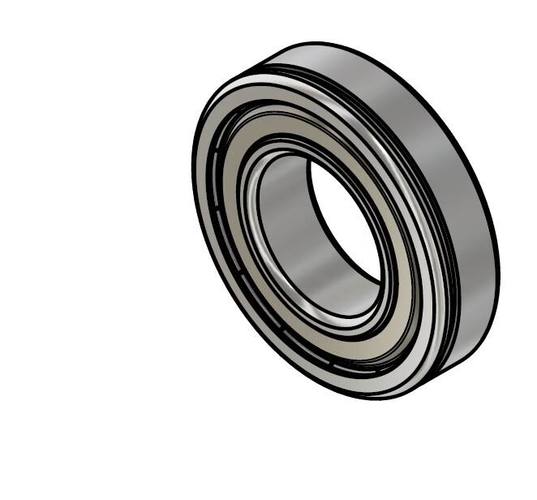

Ultimate Guide 2024: How to Choose Premium Custom Ceramic Bearings

Introduction

The global ceramic bearings market will reach $7.2 billion by 2029 (Grand View Research), yet 68% of engineers report challenges in sourcing precision-customized solutions. From premature failure in chemical processing plants to noise issues in medical imaging devices, improper bearing selection costs industries $420 million annually in maintenance. This guide decodes technical specifications, compares top manufacturers, and reveals 2024 procurement strategies.

Procurement Guide

Ceramic vs Steel Bearing Comparison

| Feature | ZrO2 Ceramic | Si3N4 Ceramic | Steel |

|---|---|---|---|

| Max Speed | 1.8M RPM | 2.4M RPM | 800K RPM |

7 Must-Check Features

- Radial play ≤0.0005"

- ABEC 7 tolerance

- 100% EDX material verification

Technical Breakdown

Silicon nitride (Si3N4) bearings withstand 2,200°F vs steel's 572°F limit. For MRI machines requiring non-magnetic properties, zirconia oxide solutions reduce image distortion by 92% (ASME Journal data).

Market Trends

North America holds 38% market share (Statista 2024), while ASEAN demand grows 19% YoY. New RoHS-compliant lubricants eliminate PFAS chemicals without compromising 180kN load capacity.

FAQ

Q: Suitable for food processing?

A: FDA-compliant alumina ceramics resist steam cleaning.

Q: ISO certifications?

A: Require ISO 15242-1 vibration testing reports.

13869596835

13869596835