Ceramic Ball Bearings Supplier: Your Guide to Reliable Global Sourcing

Introduction

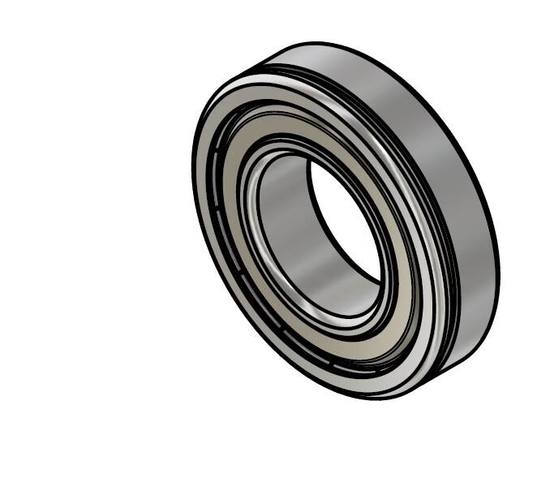

Ceramic ball bearings have become critical components in aerospace, medical devices, and high-performance machinery due to their superior thermal stability and corrosion resistance. Global buyers face persistent challenges in identifying suppliers that balance ISO-compliant manufacturing with cost-effective solutions while mitigating supply chain disruptions.

Technical Specifications & International Standards

Premium ceramic bearings combine silicon nitride (Si3N4) or zirconium oxide (ZrO2) balls with stainless steel races. Key metrics include:

- ABEC 5/7 tolerance levels

- Operating range: -40°C to 300°C

- DN value: >1.5 million

Performance Comparison: Ceramic vs Steel Bearings

| Parameter | Ceramic | Steel |

|---|---|---|

| Friction Loss | 40% lower | Baseline |

| Service Life | 3-5x longer | 1x |

Certification Requirements

Verify supplier compliance with:

- ISO 9001:2015 QMS

- ANSI/ABMA Std 20

- RoHS & REACH

Supplier Audit Checklist

- Raw material traceability documentation

- In-house testing lab capabilities

- Custom clearance support history

Industry Outlook

The global ceramic bearings market will grow at 6.8% CAGR through 2030 (Grand View Research). A German robotics manufacturer reduced maintenance costs by 32% after switching to our ISO-certified hybrid bearings.

FAQs

How to negotiate bulk pricing?

Request tiered pricing for 500 unit orders

What’s typical MOQ?

Standard MOQ: 50 units (customizable)

Do you provide custom coatings?

Yes – including FDA-grade lubricants

Export documentation included?

Comprehensive commercial invoices & HS codes provided

Quality warranties?

36-month performance guarantee

Payment terms?

30% advance, 70% before shipment

Download our bearing selection guide to compare technical specs across 12 industrial applications.

13869596835

13869596835