Top 10 Applications of Ball Bearings in Modern Industries

Ball bearings remain fundamental components in mechanical systems worldwide. These precision-engineered elements enable smooth rotation while reducing friction, making them indispensable across multiple industries. This article explores key applications of ball bearings and their critical role in modern technology.

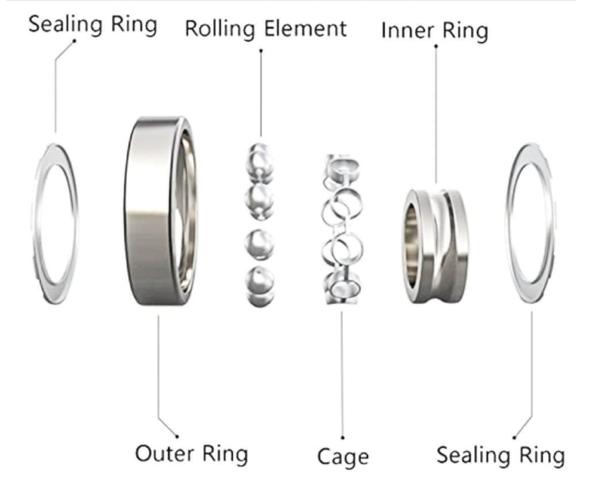

What Are Ball Bearings?

Ball bearings consist of inner/outer rings containing precision balls that facilitate rotational movement. Their primary function involves reducing friction between moving parts while supporting radial and axial loads.

Key Industrial Applications

Automotive Systems

Modern vehicles utilize ball bearings in wheels, transmissions, and engines. High-performance variants withstand extreme temperatures in racing applications.

Aerospace Technology

Specialized bearings ensure reliable operation in aircraft engines and control systems, meeting strict aviation safety standards.

Manufacturing Equipment

Industrial machinery relies on heavy-duty bearings for conveyor systems, robotic arms, and production line components.

Choosing the Right Bearing

Consider load capacity, operating environment, and rotational speed when selecting bearings. Our ISO-certified products offer various specifications for different industrial requirements.

Frequently Asked Questions

Q: How long do ball bearings typically last?

A: Properly maintained bearings can operate efficiently for 5-8 years in standard conditions.

Q: Can bearings be customized for special applications?

A: Yes, we provide custom-engineered solutions for unique operational requirements.

Enhance Your Machinery Today

Understanding applications of ball bearings helps optimize equipment performance. Explore our premium bearing solutions to improve your operational efficiency.

13869596835

13869596835