Types of Industrial Bearings: Selection Guide

Industrial bearings are the backbone of modern machinery, enabling efficient rotation while reducing friction in equipment ranging from conveyor systems to wind turbines. For international buyers, selecting the right bearing type directly impacts operational efficiency, maintenance costs, and compliance with global technical standards.

Defining Industrial Bearings: Technical Specifications & Standards

Industrial bearings are precision components classified by:

- Load type: Radial, thrust, or combined loads

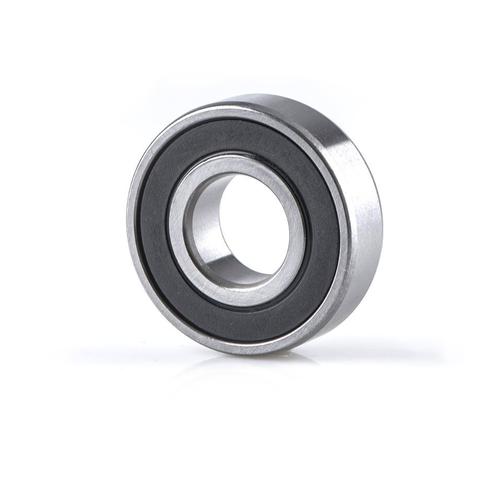

- Design: Ball bearings, roller bearings (cylindrical/tapered/spherical), plain bearings

- ISO Standards: ISO 15 (metric) & ISO 355 (tapered roller bearings)

Bearing Type Comparison Table

| Type | Load Capacity | Speed Limit | Common Applications |

|---|---|---|---|

| Deep Groove Ball | Moderate | High | Electric motors |

| Tapered Roller | High Radial/Thrust | Medium | Vehicle wheel hubs |

Cost-Efficiency Analysis

- **30% maintenance reduction** through proper bearing selection (McKinsey 2023 report)

- ISO-certified bearings show **98.6% first-year reliability** (ABMA data)

Global Certification Requirements

- ISO 9001: Quality management

- CE Marking: EU safety compliance

Supplier Audit Checklist

- Verify IATF 16949 certification for automotive applications

- Confirm material traceability documentation

FAQ

How to negotiate bulk pricing?

Request tiered pricing for orders above 500 units.

What's typical MOQ?

Standard bearings: 100-200 units; Custom designs: 500 units.

Conclusion

Download our Bearing Selection Handbook to optimize your procurement strategy.

13869596835

13869596835