1-1/2" Pillow Block Bearing - #UCP 208 24 - 208 bearing

The good news is that you don't need to replace the wheel bearings on all four wheels if only one side has worn out, but replacing the wheel bearings as a pair wouldn't be a bad idea. If the wheel bearing in the right wheel hub has gone bad, it would be better to also replace the bearings in the left wheel, but it all depends on your budget.

July 2015, Tedrail company and South Africa customers negotiate interior and vehicle hardware bus parts cooperation, and seek the casting and forging areas of cooperation.

We had a bruised and battered Mitsubishi Mirage G4 with unusually high miles, and we had to replace the wheel bearings thrice during its useful life. In one instance, the right rear wheel was wobbling badly and making loud, grinding noises, whether moving fast or creeping forward from a stop.

Railway axlebearings

Railway Axle Bearings are subject to radial impact loads caused by rail joints, switches and sometimes wheel flats, as well as to the static and dynamic radial loads of vehicle weight. They are also liable to receive axial loads generated by lateral movement as trains run on curved rails or in a snaking motion. All of these loads together form complex combinations that act on axle bearings.Axle bearings must therefore be designed on the basis of not only dimensional requirements of the axle journal and bearing box geometry, but also these complex load conditions. Additionally, as axle bearings play a critical role in the safety of railroad operation, they are periodically disassembled for inspection.Roller bearings, including tapered roller bearings, spherical roller bearings and cylindrical roller bearings, are increasingly being selected to replace plane bearings in rolling stock axles based on the particular merits of each type.

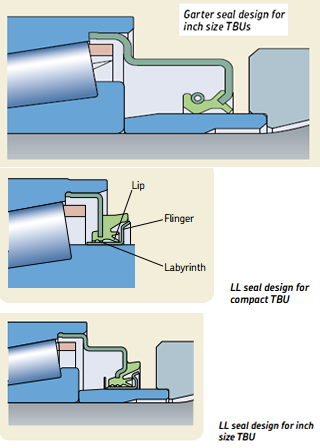

The LL (labyrinth-lip) seal design is based on a low-friction rubber seal principle that is applied to TBU and CTBU designs. The main features are a combination of labyrinth, lip and flinger elements and improved protection against contaminants to extend bearing service life. The frictional moment can be reduced by up to 75%, compared to a garter seal arrangement. As a consequence, the bearing operating temperature is reduced by 20 ℃, which contributes to longer grease life and energy savings. Results from the seal test, which evaluates water and dust exclusion, confirmed that the design is very effective in excluding contaminants. Long-term endurance tests have successfully been conducted under very severe operating conditions.

It won't be hard to tell if your vehicle has broken wheel bearings. The most common symptoms of worn wheel bearings are squealing or grinding noises that get louder the faster you go. The noise could emanate from the front or back or the left and right of the vehicle, depending on which wheel bearing is going bad. Sometimes, you might notice a humming noise or clicking sounds coming from the front or rear wheels, which could be mistaken for tire roar or road noise.

motors and generators, motors of compressors (air pumps) and drives of ventilators, actuators and charging generator of the electric and diesel locomotive engines.

NTNbearings

The bulk of the wheel bearing replacement cost is attributable to the labor. In some cars where the wheel bearings are easier to access and remove, the labor cost could be around $80 to $200. The wheel bearings cost anywhere from $40 to $120 each, depending on the vehicle. You'll have to pay more if you have a larger vehicle like a full-size SUV or heavy-duty pickup truck, which could reach over $1,000 in parts and labor.

Noisy or broken wheel bearings are a safety concern for any vehicle. It also makes some vehicles almost undrivable. If you notice strange, grinding noises while driving or feel one side of the vehicle wobbling, bring the car to a mechanic as soon as necessary before the issue worsens or the wheels fall off.

Railwaybearings

Garter seal as mentioned, the first tapered roller bearing units were designed to replace plain bearings. These inch size TBU designs had to match the existing relatively long journal dimension. This design enables the integration of a seal wear ring on both sides where the garter seals are riding. AAR has standardized these garter seals and seal wear rings, which are interchangeable with components from different bearing manufacturers. TEDRAIL can offer SKF seals according to AAR Manual of Standards and Recommended Practices Section H-Ⅱ[S723]-Roller Bearing Manual .TEDRAIL can also provide special LL seal designs for inch size TBUs that generate much lower friction

TEDRAIL supply all the range of railway axle bearings, such as Tapered Bearing Units (TBU), Compact Tapered Bearing Units (CTBU) for the applications including:

pril 2015, Tedrail and Spanish CAF company talks about cooperative development items of railway axle box for many times, and about the Railway Wheelset, railway casting forging and other asp

bearings of the axles for the goods wagons, passenger wagons, electric and diesel locomotives, electric and diesel engine vehicles and motor units which is AAR approved.

May 2015 , Tedrail and Italian pavement maintenance appropriative vehicles company,have talked about cooperative development matters for stainless steel parts . Italian company changed the

The wheel bearings consist of steel ball bearings inside the wheel hub. They enable the wheels to roll smoothly and silently while providing anchor points for the vehicle's steering, suspension, wheels, and brake components. When a wheel bearing goes bad, the affected wheel will wobble or move unnecessarily, wreaking havoc on the many undercarriage parts that rely on proper alignment to work correctly. As the problem worsens, the grinding or squealing noises get louder, which means the wheel bearings are near total failure.

Train wheel bearingsreplacement

The factory wheel bearings in your car do not require periodic maintenance and are, in most cases, designed to last the life of your vehicle. However, the grease inside the bearings could get contaminated by prolonged exposure to rain, mud, road salts, and sand. Meanwhile, overloading the vehicle or driving over speed bumps, curbs, or potholes could prematurely damage the wheel bearings.

Oldtrain wheel bearings

For instance, a faulty wheel bearing may cause uneven tire wear, wobbly steering, and an illuminated ABS (Anti-lock Braking System) warning light. An easy way to check for broken wheel bearings is to place the car on a lift or raise the affected side with a jack and a heavy-duty jack stand. Next, grab the affected wheel from both sides and try shaking it. The wheel should not move unnecessarily if the wheel bearing is solid. However, replacing the wheel bearing is necessary if it shakes or moves in its axis.

In August 2015, in celebration of the 65th anniversary of Sino-Indian diplomatic ties banquet, general manager Wenjun and deputy general manager ZhangNa of Tedrail company and Mandiri Bank o

No, we do not recommend driving a car with faulty or noisy wheel bearings. The wheels could fall off the vehicle while driving, which is not a great way to start your day. Broken wheel bearings will cause the affected wheel to wobble incessantly while the car is moving, and this will cause various issues with the steering, suspension, and brakes, like vibrations when braking or turning the wheel.

8613869596835

8613869596835