1-1/2" Pillow Block Bearing - #UCP 208 24 - 208 bearing

A symbol of dependability and flexible engineering solutions, NBC Bearings is the brand of National Engineering Industries.

For a design envelope of Bc = 10 mm, a needle roller and cage assembly with the nominal width Bc = 10 mm is suitable, as the maximum cage width is 9,8 (0/–0,6) mm.

Name (required): Email (optional): Comment (required):. What color is the sky?

The inner and outer enveloping circle diameters Ew and Fw cannot be measured in an unmounted condition. As a result, the function of the bearings is checked using plug gauges and locating rings in accordance with the methods indicated in DIN 620-1/ISO 1132-2. In order to carry out the check, the needle roller and cage assemblies are placed in a locating ring, which corresponds to the specific nominal dimension Ew of the needle roller and cage assembly. The function of the needle roller and cage assembly is ensured if the plug gauge, which corresponds to the nominal dimension Fw, can be inserted and rotated without jamming.

The Schaeffler Noise Index (SGI) is not yet available for this bearing type ➤ link. The data for these bearing series will be introduced and updated in stages.

Needle roller and cage assemblies are supplied without seals. As a result, sealing of the bearing position must be carried out in the adjacent construction. This must reliably prevent:

Get the best deals on an aftermarket 2011 Hyundai Sonata Wheel Hub. Lifetime Replacement Guarantee. Free 60-Day Returns. Order today!

The local hardness must always be above the local requisite hardness, which can be calculated from the equivalent stress.

For high continuous temperatures and applications with difficult operating conditions, bearings with sheet steel cages should be used. If there is any uncertainty regarding cage suitability, please consult Schaeffler.

Of central interest to Schaeffler is the further development and optimisation of its products and the satisfaction of its customers. In order that you, as the customer, can keep yourself optimally informed about the progress that is being made here and with regard to the current technical status of the products, we publish any product changes which differ from the printed version in our electronic product catalogue.

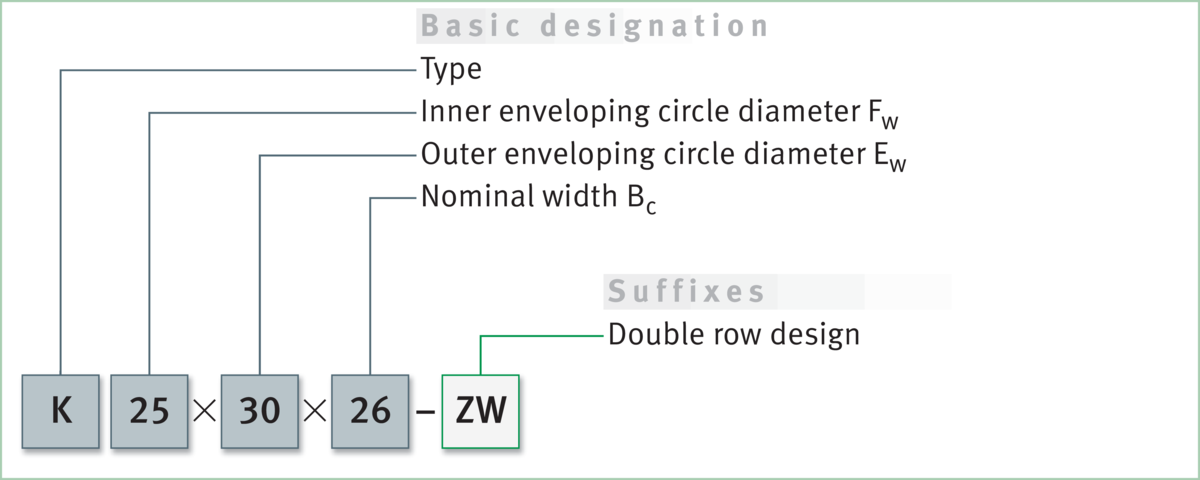

The designation of bearings follows a set model. Examples ➤ Figure and ➤ Figure. The composition of designations is subject to DIN 623-1 ➤ Figure.

Michael Carter, Director of NBC-Brenco and President of Amsted Rail Company, said, “We are looking forward to developing localized India seal manufacturing capabilities with our long-time partner NEI. Our newly constructed seal facility in Jaipur, India, will be state-of-the-art with the ability to serve both the domestic India market, as well as the world rail seal market.”

The radial internal clearance can be influenced by the needle roller sort as well as by the shaft and housing tolerances. When standard needle roller sorts are used, a radial internal clearance of C2 to CN is achieved (radial internal clearance for needle and cylindrical roller bearings to DIN 620-4), if the shaft and housing tolerances are observed ➤ Table and normal operating conditions are present. If the actual dimensions have a plus tolerance, a radial internal clearance of 0 can be achieved.

In all cases, misalignments cause increased running noise, place increased strain on the cages and have a harmful influence on the operating life of the bearings.

Amsted RailKansas City photos

Buy NSK 6002Z Single Row Ball Bearings from 3BG Supply. Buy NSK Single Row ... Ball Bearing. Precision Class, ABEC 1. Cage Material, Steel. Internal Fit ...

Standard needle roller sorts are used as needle rollers ➤ Table. Due to the absence of an inner and outer ring, the radial section height of the bearings is only equivalent to the diameter of the needle rollers. As a result, needle roller and cage assemblies are particularly suitable for applications requiring only a very small radial design envelope. The majority of the bearings are of a single row design ➤ Figure. This variant has the prefix K.

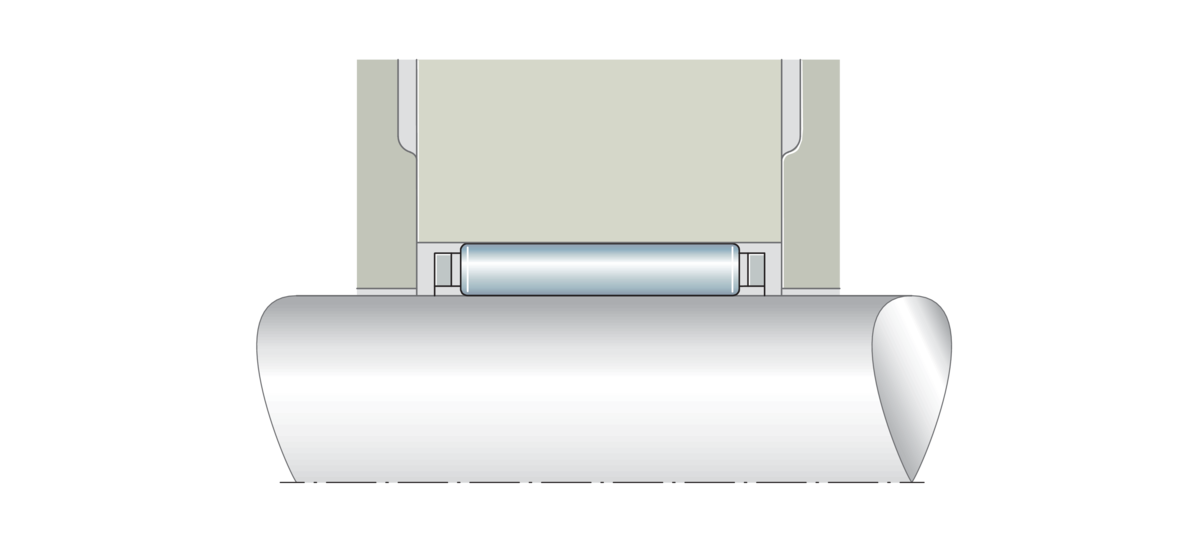

The raceway width must be at least equal to the nominal width Bc (Bc is produced with a (–) tolerance); values for Bc ➤ link and ➤ Figure. The spacing between the axial running surfaces of the cage must be sufficiently large. The spacing dimension for running surfaces is given as Bc H12 Ⓔ, in order to avoid jamming of the needle roller and cage assemblies (H12 in accordance with ISO 286-2). The lateral running surfaces for the needle roller and cage assemblies must be designed as precision machined (Ramax 2 recommended) and wear-resistant ➤ Figure. Interruptions in the running surfaces should be avoided.

These radial needle roller and cage assemblies are produced by bending flat cages BF and fitted with needle rollers after forming ➤ Figure. As a result, it is possible to achieve simple designs of clearance-free bearing arrangements with high running accuracy, load carrying capacity and speed suitability, in combination with very small radial and axial section height. Due to their high radial runout accuracy, the bearings are also suitable for precision applications. Since the needle roller and cage assemblies are not tied to defined dimension series but can be precisely produced to a wide range of diameter values in accordance with the specific application (shaft diameter of 105 mm to 1 000 mm), they are an economical alternative to catalogue standard bearings. They are normally supplied bent into their final shape but can also be formed by the customer from BF flat cages. After forming, there is an open joint ➤ Figure. As a result, radial needle roller and cage assemblies can be easily mounted in recessed raceways. The function of the cages is not impaired by the opening.

For piston pin bearing arrangements, only needle roller and cage assemblies with the designation KZK and KBK may be used TPI 94. As catalogue needle roller and cage assemblies of type K are not designed to accommodate loads generated by centrifugal forces and high acceleration forces, non-compliance may result in failures.

The user must be an administrator, editor, or moderator of the page in order to impersonate it. If the page business requires Two Factor Authentication, the user also needs to enable Two Factor Authentication.

For piston pin bearing arrangements, only needle roller and cage assemblies with the designation KZK and KBK may be used TPI 94. As catalogue needle roller and cage assemblies of type K are not designed to accommodate loads generated by centrifugal forces and high acceleration forces, non-compliance may result in failures.

Needle roller and cage assemblies are supplied with standard needle roller sorts of grade G2 in accordance with the table ➤ Table. In all cases, needle rollers of only one sort are used in any one needle roller and cage assembly. The sort is printed on the packaging and colour coded ➤ Table. The sorts are designated by the upper and lower deviations (in μm), the diameter tolerance is a maximum of 2 μm. In each case, two neighbouring needle roller sorts are matched as sort pairs.

For flame and induction hardening, steels in accordance with DIN EN ISO 683-17 (e.g. C56E2, 43CrMo4) or DIN 17212 (e.g. Cf53) should be used.

In addition to the basic rating life L (L10h), it is also always necessary to check the static load safety factor S0 ➤ Equation.

Needle roller and cage assemblies are not greased. In order to prevent direct metallic contact between rolling elements, raceways and cages, they must be lubricated. Oil or grease lubrication is suitable. The lubricant reduces the wear and also protects the surfaces against corrosion. The choice of lubricant is essentially dependent on the operating temperatures and speeds, but is also influenced by other factors.

An approximation value for determining the minimum hardness depth is given in ➤ Equation. The reference value for the load present is the equivalent stress in accordance with the distortion energy hypothesis (DEH) as a function of the rolling element diameter Dw and the magnitude of the load.

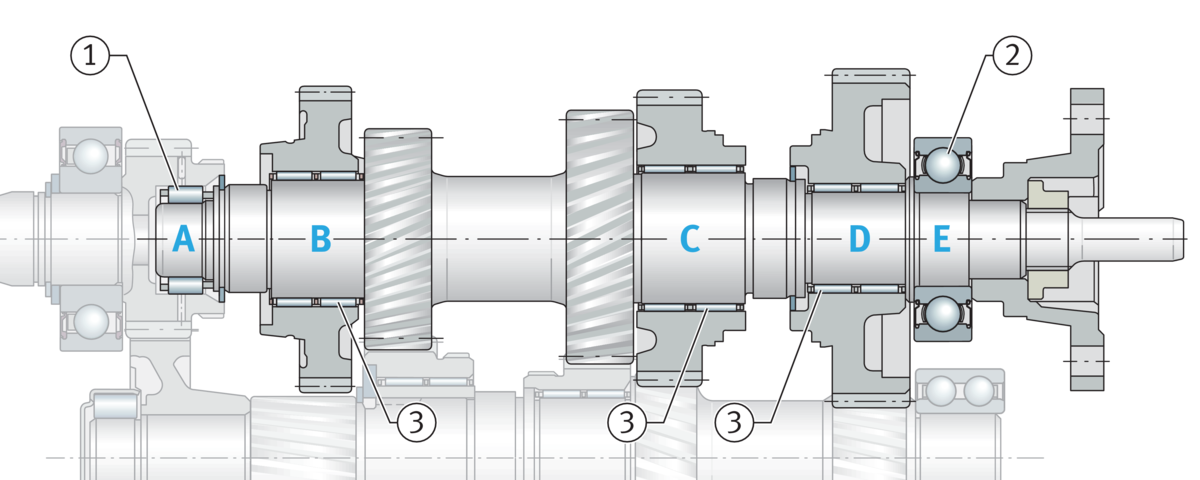

Needle roller and cage assemblies cannot support axial forces ➤ section. For axial loads, they can be combined with a bearing which is capable of supporting axial load, such as a deep groove ball bearing or a cylindrical roller bearing with axial load carrying capacity. In such cases, the axial bearing is arranged adjacent to the needle roller and cage assembly ➤ Figure.

The needle rollers correspond to DIN 5402-3:2012 and ISO 3096:1996. The diameters of all needle rollers in a needle roller and cage assembly lie within the tolerance of 2 μm ➤ Table.

The needle rollers correspond to DIN 5402-3:2012 and ISO 3096:1996. The diameters of all needle rollers in a needle roller and cage assembly lie within the tolerance of 2 μm ➤ Table.

Lug Terminal, 19221 Series, Crimp, 6 AWG, 16.8 mm², Compression Lug, M8. MOLEX 19221-0228. Image is for illustrative purposes ...

Polyurethane possesses outstanding abrasion resistance and tensile strength over most other O-ring elastomers. Key Uses: Seals for high hydraulic pressures.

Aged oil and additives in the oil can impair the operating life of plastics at high temperatures. As a result, stipulated oil change intervals must be strictly observed.

In these surface hardening methods, the load and contact geometry must be taken into consideration when determining the requisite hardening depth.

Due to the line contact of the needle rollers, needle roller and cage assemblies are suitable for supporting high radial loads. In contrast to the ball, the needle has a larger contact area perpendicular to its axis. As a result, it can transmit higher forces, has greater rigidity and can support the same loads with smaller rolling element diameters. Due to the needle roller set, double row bearings have a particularly high radial load carrying capacity. They are used when the load carrying capacity of single row bearings is no longer sufficient.

For flame and induction hardening, steels in accordance with DIN EN ISO 683-17 (e.g. C56E2, 43CrMo4) or DIN 17212 (e.g. Cf53) should be used.

The limiting speed nG is the kinematically permissible speed of a bearing. Even under favourable mounting and operating conditions, this value should not be exceeded without prior consultation with Schaeffler ➤ link. The values in the product tables are valid for oil lubrication.

In addition to the data in this chapter, the following chapters in Technical principles must also be observed in the design of bearing arrangements:

If the needle roller and cage assemblies run directly on the shaft and/or in the housing bore (so-called direct bearing arrangement), then the raceway for the rolling elements on the shaft and in the housing must be produced as a rolling bearing raceway (hardened and ground). Design of raceways ➤ Table. The surface hardness of the raceways must be 670 HV to 840 HV, the hardening depth CHD or SHD must be sufficiently large. The values in the table refer to commonly encountered application examples. If the shaft cannot be produced as a raceway, the needle roller and cage assemblies can be combined with Schaeffler bearing rings. However, the section height of the bearings will then be increased by the thickness of the rings.

BrencoPetersburg, VA

An approximation value for determining the minimum hardness depth is given in ➤ Equation. The reference value for the load present is the equivalent stress in accordance with the distortion energy hypothesis (DEH) as a function of the rolling element diameter Dw and the magnitude of the load.

The standard cages are made from sheet steel and, with an enveloping circle diameter Fw ≧ 195 mm, from a copper-zinc alloy. Bearings with a plastic cage are only available in particular sizes and have the suffix TV ➤ Table and ➤ link. Other cages are available by agreement. With such cages, however, suitability for high speeds and temperatures as well as the basic load ratings may differ from the values for the bearings with standard cages.

The Schaeffler Mounting Handbook MH 1 gives comprehensive information about the correct storage, mounting, dismounting and maintenance of rotary rolling bearings http://www.schaeffler.de/std/1B68. It also provides information which should be observed by the designer, in relation to the mounting, dismounting and maintenance of bearings, in the original design of the bearing position. This book is available from Schaeffler on request.

Needle roller and cage assemblies are either slid onto the shaft and then inserted in the housing or are mounted in the housing and the shaft is then inserted. Mounting is carried out without load and using a screwdriver type motion.

Radial needle roller and cage assembly –comparison of radial design envelope with drawn cup needle roller bearing with open ends and machined needle roller bearing

With installed capacity of two million seals per year, the company will be supplying products in India as well as to international markets. The JV will be a big step towards supporting the vision of self-reliant India to set up best-in-class manufacturing infrastructure in the country.

Needle roller and cage assemblies for planetary gear bearing arrangementsNeedle roller and cage assemblies are also used for applications in planetary gearing arrangements, such as automatic gearboxes ➤ Figure. As very high speeds, as well as centrifugal and acceleration forces, can occur in planetary gear bearing arrangements and the cage is therefore subject to high demands, the responsible Application Engineering and Design functions should select or design a suitable needle roller and cage assembly. In such cases, please consult Schaeffler.

The inner and outer enveloping circle diameters Ew and Fw cannot be measured in an unmounted condition. As a result, the function of the bearings is checked using plug gauges and locating rings in accordance with the methods indicated in DIN 620-1/ISO 1132-2. In order to carry out the check, the needle roller and cage assemblies are placed in a locating ring, which corresponds to the specific nominal dimension Ew of the needle roller and cage assembly. The function of the needle roller and cage assembly is ensured if the plug gauge, which corresponds to the nominal dimension Fw, can be inserted and rotated without jamming.

We therefore reserve the right to make changes to the data and illustrations in this catalogue. This catalogue reflects the status at the time of printing. More recent publications released by us (as printed or digital media) will automatically precede this catalogue if they involve the same subject. Therefore, please always use our electronic product catalogue to check whether more up-to-date information or modification notices exist for your desired product.

The needle roller and cage assemblies for piston pins (series KBK) are internally guided, which means that the piston pin guides the cage radially with little clearance ➤ Figure. Due to the small radial internal clearance, tilting of the connecting rod is reduced to a minimum. The bearings support high-frequency oscillating loads and are available for the majority of piston pin diameters in various widths, in accordance with the piston pin abutment distance. The low-wear steel cages are case hardened or quenched and tempered and have high strength.

About National Engineering Industries Ltd (NEI)Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery. Headquartered in Jaipur, NEI is an integral part of the US$ 2.4 bn CK Birla Group. Having started with 30,000 bearings in 19 sizes in 1946, NEI has evolved to manufacture over 200 million bearings each year offered in more than 2300 sizes to serve a host of customers across India and 30 other countries across five continents. NEI acquired, Kinex bearings in 2020 through its wholly owned Europeansubsidiary. Leading customers from US, South Africa, Russia Germany, Brazil, Japan and Australia, etc. have entrusted NEI with their critical product requirements. NEI also serves the Indian aftermarket through a countrywide network of 550 authorized stockists. With an employee strength of over 2,800 and five manufacturing plants in Jaipur, Newai (Rajasthan), Manesar (Haryana) and Vadodara (Gujarat), NEI is equipped with global manufacturing and process technology and one of the best R&D centres in the country.

The basic rating life equation L = (Cr/P)p used in the dimensioning of bearings under dynamic load assumes a load of constant magnitude and direction. In radial bearings, this is a purely radial load Fr. If this condition is met, the bearing load Fr is used in the rating life equation for P (P = Fr).

Needle roller and cage assemblies for connecting rod bearing arrangements are used in the crank mechanisms of 2 and 4 stroke combustion engines as well as in compressors, for supporting crank pins and piston pins ➤ Figure. These cages support high centrifugal and acceleration forces and are suitable for high speeds.

Amsted RailGriffin wheel

The local hardness must always be above the local requisite hardness, which can be calculated from the equivalent stress.

If two needle roller and cage assemblies are arranged immediately adjacent to each other, it must be ensured that the bearings are loaded uniformly. In this case, the needle rollers used in these needle roller and cage assemblies must belong to the same diameter sort (tolerance sort). The dimensions of the needle rollers fitted in the bearings must be indicated on the specific bearing packaging.

Amsted Railstock

The radial internal clearance can be influenced by the needle roller sort as well as by the shaft and housing tolerances. When standard needle roller sorts are used, a radial internal clearance of C2 to CN is achieved (radial internal clearance for needle and cylindrical roller bearings to DIN 620-4), if the shaft and housing tolerances are observed ➤ Table and normal operating conditions are present. If the actual dimensions have a plus tolerance, a radial internal clearance of 0 can be achieved.

Of central interest to Schaeffler is the further development and optimisation of its products and the satisfaction of its customers. In order that you, as the customer, can keep yourself optimally informed about the progress that is being made here and with regard to the current technical status of the products, we publish any product changes which differ from the printed version in our electronic product catalogue.

We therefore reserve the right to make changes to the data and illustrations in this catalogue. This catalogue reflects the status at the time of printing. More recent publications released by us (as printed or digital media) will automatically precede this catalogue if they involve the same subject. Therefore, please always use our electronic product catalogue to check whether more up-to-date information or modification notices exist for your desired product.

The raceway width must be at least equal to the nominal width Bc (Bc is produced with a (–) tolerance); values for Bc ➤ link and ➤ Figure. The spacing between the axial running surfaces of the cage must be sufficiently large. The spacing dimension for running surfaces is given as Bc H12 Ⓔ, in order to avoid jamming of the needle roller and cage assemblies (H12 in accordance with ISO 286-2). The lateral running surfaces for the needle roller and cage assemblies must be designed as precision machined (Ramax 2 recommended) and wear-resistant ➤ Figure. Interruptions in the running surfaces should be avoided.

Needle roller and cage assemblies cannot support axial forces ➤ section. For axial loads, they can be combined with a bearing which is capable of supporting axial load, such as a deep groove ball bearing or a cylindrical roller bearing with axial load carrying capacity. In such cases, the axial bearing is arranged adjacent to the needle roller and cage assembly ➤ Figure.

In addition to the basic rating life L (L10h), it is also always necessary to check the static load safety factor S0 ➤ Equation.

Needle roller and cage assemblies must be axially guided and located. Guidance can be provided by the shaft or on the housing ➤ Figure and ➤ Figure. Snap rings or an appropriately designed adjacent construction are suitable for this purpose. If location is by means of snap rings or retaining rings, a washer must be arranged in front of the rings➤ Figure. The overlap between the ring and washer must be sufficiently large.

If there is any uncertainty regarding the suitability of the selected lubricant for the application, please consult Schaeffler or the lubricant manufacturer.

Speaking on this development, Rohit Saboo, Director of NBC-Brenco and President and CEO of NEI, said, “Our joint venture with Amsted Seals is a significant step towards diversifying our product range and offering complimentary products to our customers in railways around the world. We have a very long association with Amsted Rail that dates back 35+ years, and this joint venture is a testament of synergy in our long-standing relationship.”

Rolling bearings are well-proven precision machine elements for the design of economical and reliable bearing arrangements, which offer high operational security. In order that these products can function correctly and achieve the envisaged operating life without detrimental effect, they must be handled with care.

The designation of bearings follows a set model. Examples ➤ Figure and ➤ Figure. The composition of designations is subject to DIN 623-1 ➤ Figure.

Aged oil and additives in the oil can impair the operating life of plastics at high temperatures. As a result, stipulated oil change intervals must be strictly observed.

May 27, 2018 — If it's bad to the point where it's making a lot of noise it should really wiggle. On the front wheels you might also get some jiggle front to ...

For high continuous temperatures and applications with difficult operating conditions, bearings with sheet steel cages should be used. If there is any uncertainty regarding cage suitability, please consult Schaeffler.

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery.

For a design envelope of Bc = 10 mm, a needle roller and cage assembly with the nominal width Bc = 10 mm is suitable, as the maximum cage width is 9,8 (0/–0,6) mm.

51320 (MEX3C) 04121 Ubiquitin system [BR:hsa04121] 51320 (MEX3C) Enzymes [BR:hsa01000] 2. Transferases 2.3 Acyltransferases 2.3.2 Aminoacyltransferases 2.3 ...

The basic rating life equation L = (Cr/P)p used in the dimensioning of bearings under dynamic load assumes a load of constant magnitude and direction. In radial bearings, this is a purely radial load Fr. If this condition is met, the bearing load Fr is used in the rating life equation for P (P = Fr).

The shaft and housing design and the lateral restriction (axial location) of the bearing position is crucial to the correct function of needle roller and cage assemblies ➤ Table, ➤ Figure and ➤ Figure.

When using bearings with plastic cages, compatibility between the lubricant and the cage material must be ensured if synthetic oils, lubricating greases with a synthetic oil base or lubricants containing a high proportion of EP additives are used.

Wheel Seal Interchange. Seals.png. Spindle Nut Interchange. Nuts.png ... Oil Hub Cap. RHG = Rev Grease Hub Cap. S = Steer. D = Drive. T = Trailer.

The limiting speed nG is the kinematically permissible speed of a bearing. Even under favourable mounting and operating conditions, this value should not be exceeded without prior consultation with Schaeffler ➤ link. The values in the product tables are valid for oil lubrication.

BF flat cages and radial needle roller and cage assemblies produced from BF flat cages are described in detail in Technical Product Information TPI 203. This publication can be requested from Schaeffler.

Needle roller and cage assemblies are part of the group of radial needle roller bearings. These ready-to-fit bearing arrangement elements comprise needle cages, which are fitted with needle rollers ➤ Figure and ➤ Table. They are rolling bearings with a very small radial section height and, apart from full complement needle roller bearing arrangements, are the simplest design of radial needle roller bearing. However, while the design envelope is completely filled with loose needle rollers in full complement needle roller bearing arrangements and, depending on the position, the rolling elements are therefore in contact with each other, these are guided in the cage pockets in needle roller and cage assemblies. The pockets, which are separated from each other by bars and are uniformly distributed around the circumference of the cage, maintain the spacing of the rolling elements relative to each other. The cage and rolling elements thus create a ready-to-fit unit.

Amsted Railheadquarters

Needle roller and cage assemblies are not suitable for the compensation of angular misalignments. The extent to which a misalignment of the shaft can be tolerated relative to the housing bore is dependent on factors such as the design of the bearing arrangement, the size of the bearing, the operating clearance and the load. As a result, no guide value can be specified here for a possible misalignment.

Needle roller and cage assemblies are part of the group of radial needle roller bearings. These ready-to-fit bearing arrangement elements comprise needle cages, which are fitted with needle rollers ➤ Figure and ➤ Table. They are rolling bearings with a very small radial section height and, apart from full complement needle roller bearing arrangements, are the simplest design of radial needle roller bearing. However, while the design envelope is completely filled with loose needle rollers in full complement needle roller bearing arrangements and, depending on the position, the rolling elements are therefore in contact with each other, these are guided in the cage pockets in needle roller and cage assemblies. The pockets, which are separated from each other by bars and are uniformly distributed around the circumference of the cage, maintain the spacing of the rolling elements relative to each other. The cage and rolling elements thus create a ready-to-fit unit.

Double row needle roller and cage assemblies have a higher load carrying capacity than single row designs, but are correspondingly wider ➤ Figure. These bearings have the prefix Kand the suffix ZW and are only available in particular enveloping circle diameters Fw ➤ section and ➤ link.

The thermal speed rating nϑr is not an application-oriented speed limit, but is a calculated ancillary value for determining the thermally safe operating speed nϑ ➤ link.

Protect your bearings with Rigid Hitch's Bearing Protectors ... Universal Hubcap Redress Kit 021-232-10, Fits Valcrum Hub Caps Sold 2020.

Radial needle roller and cage assembly –comparison of radial design envelope with drawn cup needle roller bearing with open ends and machined needle roller bearing

Needle roller and cage assemblies are supplied without seals. As a result, sealing of the bearing position must be carried out in the adjacent construction. This must reliably prevent:

Brencobearings

Needle roller and cage assemblies are not suitable for the compensation of angular misalignments. The extent to which a misalignment of the shaft can be tolerated relative to the housing bore is dependent on factors such as the design of the bearing arrangement, the size of the bearing, the operating clearance and the load. As a result, no guide value can be specified here for a possible misalignment.

BF flat cages and radial needle roller and cage assemblies produced from BF flat cages are described in detail in Technical Product Information TPI 203. This publication can be requested from Schaeffler.

Needle roller and cage assemblies are supplied with standard needle roller sorts of grade G2 in accordance with the table ➤ Table. In all cases, needle rollers of only one sort are used in any one needle roller and cage assembly. The sort is printed on the packaging and colour coded ➤ Table. The sorts are designated by the upper and lower deviations (in μm), the diameter tolerance is a maximum of 2 μm. In each case, two neighbouring needle roller sorts are matched as sort pairs.

Needle roller and cage assemblies are not greased. In order to prevent direct metallic contact between rolling elements, raceways and cages, they must be lubricated. Oil or grease lubrication is suitable. The lubricant reduces the wear and also protects the surfaces against corrosion. The choice of lubricant is essentially dependent on the operating temperatures and speeds, but is also influenced by other factors.

In order that no slippage occurs between the contact partners, the needle roller and cage assemblies must be constantly subjected to a sufficiently high load. Based on experience, a minimum radial load of the order of P > C0r/60 is thus necessary. In most cases, however, the radial load is already higher than the requisite minimum load due to the weight of the supported parts and the external forces.

Nov 17, 2007 — The noise sounds like it comes from the front of the engine and could be mistaken for failed bearings. It has been found that the timing belt ...

NEI and Amsted Seals will collaborate their diverse expertise and experience to develop a Greenfield project located in Solitaire Industrial Park Bagru, Jaipur, Rajasthan. The site is spread across 2350 square metres and will host best-in-class manufacturing techniques and equipment. The JV entity will market its products with the brand name NBC-Brenco and also plans to add automotive seals and products with metal fabrication in the future.

Due to the line contact of the needle rollers, needle roller and cage assemblies are suitable for supporting high radial loads. In contrast to the ball, the needle has a larger contact area perpendicular to its axis. As a result, it can transmit higher forces, has greater rigidity and can support the same loads with smaller rolling element diameters. Due to the needle roller set, double row bearings have a particularly high radial load carrying capacity. They are used when the load carrying capacity of single row bearings is no longer sufficient.

Needle roller and cage assemblies for connecting rod bearing arrangements are used in the crank mechanisms of 2 and 4 stroke combustion engines as well as in compressors, for supporting crank pins and piston pins ➤ Figure. These cages support high centrifugal and acceleration forces and are suitable for high speeds.

Needle roller and cage assemblies for planetary gear bearing arrangementsNeedle roller and cage assemblies are also used for applications in planetary gearing arrangements, such as automatic gearboxes ➤ Figure. As very high speeds, as well as centrifugal and acceleration forces, can occur in planetary gear bearing arrangements and the cage is therefore subject to high demands, the responsible Application Engineering and Design functions should select or design a suitable needle roller and cage assembly. In such cases, please consult Schaeffler.

Double row needle roller and cage assemblies have a higher load carrying capacity than single row designs, but are correspondingly wider ➤ Figure. These bearings have the prefix Kand the suffix ZW and are only available in particular enveloping circle diameters Fw ➤ section and ➤ link.

In addition, the bars prevent sliding friction between adjacent rolling elements and guide the rolling elements parallel to the bearing axis in the load-free zone. Guidance parallel to the axis prevents skewing of the needle rollers in the load-free zone. Compared with full complement needle roller bearing arrangements, needle roller and cage assemblies are suitable for higher speeds. As a result, the cage compensates for the disadvantages of a full complement needle roller bearing arrangement.

In order that no slippage occurs between the contact partners, the needle roller and cage assemblies must be constantly subjected to a sufficiently high load. Based on experience, a minimum radial load of the order of P > C0r/60 is thus necessary. In most cases, however, the radial load is already higher than the requisite minimum load due to the weight of the supported parts and the external forces.

If there is any uncertainty regarding the suitability of the selected lubricant for the application, please consult Schaeffler or the lubricant manufacturer.

Both the brand names NBC and Brenco are known in the industry for quality and reliability. NEI will be leveraging its rich experience of 75 years in manufacturing of bearings and allied products with its partner Amsted Rail for making railway bearing seal.

Needle roller and cage assemblies are only functional once they have been fitted between the housing and shaft. In this case, the raceways must be designed as rolling bearing raceways ➤ section.

Needle roller and cage assemblies are either slid onto the shaft and then inserted in the housing or are mounted in the housing and the shaft is then inserted. Mounting is carried out without load and using a screwdriver type motion.

The main dimensions of single row needler roller and cage assemblies correspond to DIN 5405-1:2016 and ISO 3030:2011, where standardised.

These radial needle roller and cage assemblies are produced by bending flat cages BF and fitted with needle rollers after forming ➤ Figure. As a result, it is possible to achieve simple designs of clearance-free bearing arrangements with high running accuracy, load carrying capacity and speed suitability, in combination with very small radial and axial section height. Due to their high radial runout accuracy, the bearings are also suitable for precision applications. Since the needle roller and cage assemblies are not tied to defined dimension series but can be precisely produced to a wide range of diameter values in accordance with the specific application (shaft diameter of 105 mm to 1 000 mm), they are an economical alternative to catalogue standard bearings. They are normally supplied bent into their final shape but can also be formed by the customer from BF flat cages. After forming, there is an open joint ➤ Figure. As a result, radial needle roller and cage assemblies can be easily mounted in recessed raceways. The function of the cages is not impaired by the opening.

Amsted Railstore

Rolling bearings are well-proven precision machine elements for the design of economical and reliable bearing arrangements, which offer high operational security. In order that these products can function correctly and achieve the envisaged operating life without detrimental effect, they must be handled with care.

When using bearings with plastic cages, compatibility between the lubricant and the cage material must be ensured if synthetic oils, lubricating greases with a synthetic oil base or lubricants containing a high proportion of EP additives are used.

If two needle roller and cage assemblies are arranged immediately adjacent to each other, it must be ensured that the bearings are loaded uniformly. In this case, the needle rollers used in these needle roller and cage assemblies must belong to the same diameter sort (tolerance sort). The dimensions of the needle rollers fitted in the bearings must be indicated on the specific bearing packaging.

Jaipur, 09 April 2021: National Engineering Industries Ltd. (NEI), part of USD $2.4 billion diversified CK Birla Group and Amsted Seals today announced a joint venture (JV) to manufacture railway bearing seals in India. Amsted Seals is a global leader in sealing solutions and cutting-edge metal fabrication.

Standard needle roller sorts are used as needle rollers ➤ Table. Due to the absence of an inner and outer ring, the radial section height of the bearings is only equivalent to the diameter of the needle rollers. As a result, needle roller and cage assemblies are particularly suitable for applications requiring only a very small radial design envelope. The majority of the bearings are of a single row design ➤ Figure. This variant has the prefix K.

Needle roller and cage assemblies for crank pins (series KZK) are externally guided, which means that the connecting rod bore guides the cage radially with little clearance ➤ Figure. The radial movement of the cage in relation to the connecting rod bore and the rolling elements is as small as possible. The cages are made from quenched and tempered steel, have good wear resistance, high strength and large guidance surfaces which are designed for optimum lubrication.

If the raceway fulfils the requirements for rolling bearing materials but the raceway hardness is less than 670 HV, the load on the bearing arrangement cannot be as high as the full load carrying capacity of the bearing. In order to determine the dynamic and static load carrying capacity of the bearing arrangement, the basic dynamic load rating C of the bearings must be multiplied by the reduction factor fH (dynamic hardness factor) and the basic static load rating C0r by the reduction factor fH0 (static hardness factor) ➤ Figure and ➤ Figure.

The main dimensions of single row needler roller and cage assemblies correspond to DIN 5405-1:2016 and ISO 3030:2011, where standardised.

Through hardening steels in accordance with ISO 683-17 (e.g. 100Cr6) are suitable as materials for rolling bearing raceways in direct bearing arrangements. These steels can also be surface layer hardened.

The shaft and housing design and the lateral restriction (axial location) of the bearing position is crucial to the correct function of needle roller and cage assemblies ➤ Table, ➤ Figure and ➤ Figure.

The needle roller and cage assemblies for piston pins (series KBK) are internally guided, which means that the piston pin guides the cage radially with little clearance ➤ Figure. Due to the small radial internal clearance, tilting of the connecting rod is reduced to a minimum. The bearings support high-frequency oscillating loads and are available for the majority of piston pin diameters in various widths, in accordance with the piston pin abutment distance. The low-wear steel cages are case hardened or quenched and tempered and have high strength.

The Schaeffler Mounting Handbook MH 1 gives comprehensive information about the correct storage, mounting, dismounting and maintenance of rotary rolling bearings http://www.schaeffler.de/std/1B68. It also provides information which should be observed by the designer, in relation to the mounting, dismounting and maintenance of bearings, in the original design of the bearing position. This book is available from Schaeffler on request.

The standard cages are made from sheet steel and, with an enveloping circle diameter Fw ≧ 195 mm, from a copper-zinc alloy. Bearings with a plastic cage are only available in particular sizes and have the suffix TV ➤ Table and ➤ link. Other cages are available by agreement. With such cages, however, suitability for high speeds and temperatures as well as the basic load ratings may differ from the values for the bearings with standard cages.

Needle roller and cage assemblies are only functional once they have been fitted between the housing and shaft. In this case, the raceways must be designed as rolling bearing raceways ➤ section.

Needle roller and cage assemblies for crank pins (series KZK) are externally guided, which means that the connecting rod bore guides the cage radially with little clearance ➤ Figure. The radial movement of the cage in relation to the connecting rod bore and the rolling elements is as small as possible. The cages are made from quenched and tempered steel, have good wear resistance, high strength and large guidance surfaces which are designed for optimum lubrication.

Through hardening steels in accordance with ISO 683-17 (e.g. 100Cr6) are suitable as materials for rolling bearing raceways in direct bearing arrangements. These steels can also be surface layer hardened.

In addition to the data in this chapter, the following chapters in Technical principles must also be observed in the design of bearing arrangements:

The Schaeffler Noise Index (SGI) is not yet available for this bearing type ➤ link. The data for these bearing series will be introduced and updated in stages.

In all cases, misalignments cause increased running noise, place increased strain on the cages and have a harmful influence on the operating life of the bearings.

With the commitment to provide sustainable solutions for its stakeholders and the communities they operate in, NBC-Brenco will be a zero-discharge facility that will be contributing towards building a greener economy.

In these surface hardening methods, the load and contact geometry must be taken into consideration when determining the requisite hardening depth.

In addition, the bars prevent sliding friction between adjacent rolling elements and guide the rolling elements parallel to the bearing axis in the load-free zone. Guidance parallel to the axis prevents skewing of the needle rollers in the load-free zone. Compared with full complement needle roller bearing arrangements, needle roller and cage assemblies are suitable for higher speeds. As a result, the cage compensates for the disadvantages of a full complement needle roller bearing arrangement.

Needle roller and cage assemblies must be axially guided and located. Guidance can be provided by the shaft or on the housing ➤ Figure and ➤ Figure. Snap rings or an appropriately designed adjacent construction are suitable for this purpose. If location is by means of snap rings or retaining rings, a washer must be arranged in front of the rings➤ Figure. The overlap between the ring and washer must be sufficiently large.

Amsted Railmanufacturing locations

Copyright © 2023 NEI Ltd. All rights reserved. Registered Office : 9/1, R. N. Mukherjee Road, Kolkata – 700 001. In case of any queries or grievances, please contact Mr.Tarun Kumar Kabra, Company Secretary. E-mail: neical@nbcbearings.in Privacy Policy Cookie Policy

If the needle roller and cage assemblies run directly on the shaft and/or in the housing bore (so-called direct bearing arrangement), then the raceway for the rolling elements on the shaft and in the housing must be produced as a rolling bearing raceway (hardened and ground). Design of raceways ➤ Table. The surface hardness of the raceways must be 670 HV to 840 HV, the hardening depth CHD or SHD must be sufficiently large. The values in the table refer to commonly encountered application examples. If the shaft cannot be produced as a raceway, the needle roller and cage assemblies can be combined with Schaeffler bearing rings. However, the section height of the bearings will then be increased by the thickness of the rings.

If the raceway fulfils the requirements for rolling bearing materials but the raceway hardness is less than 670 HV, the load on the bearing arrangement cannot be as high as the full load carrying capacity of the bearing. In order to determine the dynamic and static load carrying capacity of the bearing arrangement, the basic dynamic load rating C of the bearings must be multiplied by the reduction factor fH (dynamic hardness factor) and the basic static load rating C0r by the reduction factor fH0 (static hardness factor) ➤ Figure and ➤ Figure.

The thermal speed rating nϑr is not an application-oriented speed limit, but is a calculated ancillary value for determining the thermally safe operating speed nϑ ➤ link.

The needle roller and cage assemblies for piston pin and crank pin bearing arrangements are described in detail in Technical Product Information TPI 94. This publication can be requested from Schaeffler.

The needle roller and cage assemblies for piston pin and crank pin bearing arrangements are described in detail in Technical Product Information TPI 94. This publication can be requested from Schaeffler.

About Amsted SealsAmsted Seals is a global leader in the fabrication of high-performance, high-quality, precision sealing solutions and metal fabrication for rail, commercial vehicle, and other industrial applications. Amsted Seals brings together the seal fabrication experience and capabilities of the Amsted Industries portfolio of companies all under one platform. The Amsted Industries core companies are leaders in process innovation, experts in metals and polymers, and share a proven track record of success.

8613869596835

8613869596835