1/2 x 1-1/4 Spindle King Pin Ball Bearing - 1/4 in bearing

6002 Bearing Size; 0.3mm Radius min. 2850N Static Load; Double Seal (2RS) Type; 6002-2RS Series Code; 14000 RPM Max Grease. Discover more about the Rotary ...

608-2rsbearingspecifications

Fatigue of a copper based lining starts from fatigue of the overlay. The overlay flakes out from the copper lining resulting in breaking the oil film and changing the lubrication regime from hydrodynamic to boundary. The load localizes at the contact area causing formation of small cracks on the lining surface. The cracks then spread throughout the lining thickness, meet the steel back surface and continue to advance along the steel-copper boundary. As a result parts of the intermediate layer detach from the steel surface. Fatigue of copper lining causes immediate engine failure. to top

608-2rsbearingnear me

Mean annual air temperature ranges from 7 to 12 degrees C (44 to 53 degrees F), mean annual precipitation ranges from 740 to 1020 mm (29 to 40 inches), frost ...

Dec 30, 2008 — If there's any play in the tire when doing this, that bearing is bad. The other is to place your hand on the strut spring, and then slowly ...

Bearing608Z

While they can be tricky to remove and replace, with a little elbow grease and know-how, you can repair your worn out wheel bearings.

6082Bearingdimensions

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Fatigue of an overlay appears in form of a network of thin cracks. Thinner overlays form thinner fatigue cracks. Fatigue limit of an overlay is determined by the strength of the material and the thickness of the overlay. The thinner the overlay the higher its fatigue strength. Overlay fatigue itself does not cause the engine failure. However running the bearing with fatigued overlay for a long time may cause partial flaking of the overlay and lowering the oil film thickness. The conditions for boundary lubrication occurred at low oil film thickness lead to excessive wear and localized loading, which may result in the failure of the lining (intermediate layer). to top

608bearingdimensions

Take a Ram 2500. Two engine options. Gas 6.4L Hemi making 410 HP and ... 375 upvotes · 533 comments. r/cars icon. r/cars. • 15 days ago ...

The major type of engine bearing failure is Fatigue. Fatigue of engine bearing materials is caused by running the bearing at a load above the fatigue limit. The causes of engine bearing fatigue:

608-2rsbearingdimensions

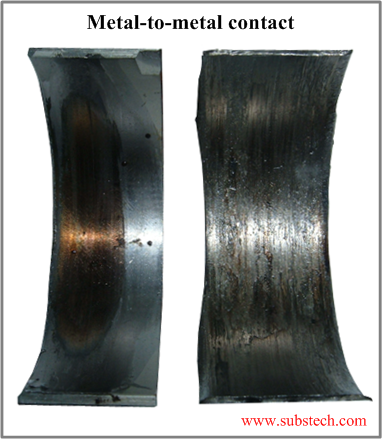

Distorted (bent or twisted connecting rod) is one of the causes of localized loading of engine bearings. Overloading of an internal combustion engine due to detonation or running under high torque at low rotation speed may cause distortion of the connecting rods. The distortion results in non-parallel orientation of the bearing and journal surfaces. The misalignment causes localized excessive wear of the bearing surface due to metal-to-metal contact (boundary lubrication) occurring near the bearing edge. Localized metal-to-metal contact may also cause Fatigue cracking of the Engine bearing materials in the locations of the contact. to top

Physical signs of wheel hub assembly failure · Wheel vibration and/or wobble · Loose steering wheel · The vehicle pulls to the side when the brakes are applied.

608bearingdimensions in mm

Cavitation occurs when the load applied to the bearing fluctuates at high frequency (high RPM). The oil pressure instantly falls causing formation of cavities due to fast evaporation (boiling). When the pressure rises the vapor cavities (cavitation bubbles) contract at high velocity. Such collapse results in impact pressure, which may erode the bearing material. The oil pressure creates a supporting force separating the journal from the bearing surface. Soft Lead based engine bearing overlays of tri-metal bearings are prone to the cavitation erosion. to top

2023320 — V- belts pulleys differ from timing belt pulleys for the type of belt ( V-section) they fit in. Sati has in stock a wide range of V- belt pulley ...

Imperfect journal geometry is also a cause of localized loading of engine bearings. Use of a worn stone in grinding a crankshaft results in obtaining an imperfect (out-of-shape) journal surface: taper shape, hour glass shape or barrel shape. The parts of the journal surface having higher diameter (central part of the barrel shape journal, edge parts of hour glass shape journal) come to metal-to metal contact (boundary lubrication) with the bearing surface. The metal-to-metal contact causes excessive wear. Fatigue cracking of the Engine bearing materials may occur in the contact areas. to top

8x22x7Bearing

Cooper offers a wide variety of housing options to suit specific bearing types. These encompass housings for cylindrical roller bearings, housings for tapered ...

Dr. Dmitri Kopeliovich Engine bearings are small and relatively inexpensive components of internal combustion engines however failure of an engine bearing commonly leads to serious reconditioning works of the engine including its disassembling, regrinding the crankshaft and replacing the bearings. Factors affecting normal functioning of engine bearings:

Plain bearings are used to transmit rotating, sliding, reciprocating, and oscillatory motions. While the journal glides on the bearing's inner surface, the ...

Appearance of fatigue of aluminum based lining is similar to that of copper base lining. It is also result of overloading caused by running the engine under high loads (torque) at low rotation speeds for long period, localized loading of the bearing due to a misalignment, fuel detonation or other factors. The fatigue cracks form on the surface and spread inside the lining reaching the steel back. The cracks then progress along the bond line between the lining and the steel. Pieces of the lining flake out from the steel back resulting in the engine failure. Fatigue of aluminum alloys may also cause extrusion of the lining material out of the bearing edges. to top

Looking for premium 2014 Nissan Altima Hub bearing at prices that compete with the best in the market? A-Premium's got what you need! Same Day Shipping.

SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

8613869596835

8613869596835