12000W 6000*2500 Exchange Platform Fiber Laser ... - 6000/2500

Howdo they make steel BBs

Founded in 1918, NTN is one of the world's largest producers of premium quality ball and roller bearings, long recognized for the most stringent quality standards in the industry. With plants around the globe and a strong domestic manufacturing network, over 80% of the products sold by NTN in North America are made by one of the ten plants the company operates in Canada and the USA. NTN is also a leading provider of bearing services which include technical support, maintenance and reliability services, engineering consulting and training. NTN's company vision is "to transform into Canada’s leader of the Ultimate Bearing Experience."

* Use our part lookup to find out if BCA Axle Shaft Repair Bearings are available for your application here: https://bcabearings.com/catalog/search/

The balls are then tumbled to remove the flash. In this process the balls are repeatedly fed into the grooves between two cast iron disks, with one disk rotating and the other stationary. The rough grooves effectively tear off the flash, and leave the ball fairly round and slightly oversized to allow for grinding. Next, the balls undergo a heat-treating process similar to that of the raceways to increase durability, before they are ground down to the proper size and roundness.

Finally, the balls are moved to a lapping machine, which polishes them using soft cast iron disks, similar to the tumbling process, and low amounts of pressure. A polishing paste is used to make the surface perfectly smooth without further removing material. Balls remain in the lapping machine for 8-10 hours to produce a completely smooth ball.

Alternative processes to ball bearing construction exist as well, such as making “space balls.” Bearing balls can be created on a space shuttle, where melted blobs of steel are left to float freely in zero gravity, forming completely perfect spheres. This process, however, is also more expensive than grinding and lapping, leaving us with the old and trusted methods of polishing on Earth.

With all of the bearing parts constructed, the bearing is ready to be assembled. First, the inner ring is placed inside the outer ring. Then the balls are inserted and spaced evenly between the raceways. Finally, the cage is installed to keep the balls in place. Plastic cages are easily snapped in, while steel cages typically need to be riveted together. The bearing is then coated with a rust preservative, or other special finishes for specific applications, and packaged for shipping.

HowBBsaremade

Ball bearings have been used to facilitate rotary movement for hundreds of years. They were first patented by Philip Vaughan to support a carriage axle in 1794, and have since been improved upon and varied to support a multitude of rotary applications. This article will describe the modern process used to create the ball bearings widely used today, from the construction of the balls to part assembly and packaging.

Product analysis Technical assistance Audit of assembly lines Aerospace inspection and repair Training Distributor Online Quality Documentation

Ball bearings are inexpensive to produce and have been trusted in their job for hundreds of years. There are alternatives to these bearings, such as bearings that utilize magnets or compressed air to prevent the two objects from contact altogether, however these technologies are far more expensive to produce and operate.

Ballmanufacturing

The raceways are finished using grinding wheels, as they are now too hard to cut with cutting tools, to reach desired dimensions. Every part of the rings must be ground to ensure proper bearing width, radius, race location and geometry. Some bearings, such as angular contact bearings, require additional grinding later on in the process to make sure the rings are the proper dimensions.

Most bearings and bearing parts are made of steel, due to its durability and strength under strenuous conditions. The most common type of steel used is SAE 52100, a chrome steel containing 1% carbon and 1.5% chrome alloy. This material is stable in temperatures over 250 degrees Fahrenheit and provides a dependable bearing with long operating life. Some ball cages are constructed from polyamide plastics to reduce production costs, but this material is not always suitable for harsh conditions, especially high temperature applications.

Keeping in line with our Spirit Tree philosophy, we conduct our business with high respect and regard for the environment and the communities we serve.

Ballbearing production process

We are pleased to introduce our new special column, “Pitter’s Corner”. With more than 30 years of industry experience, NTN Industry Expert, Automotive & HD Aftermarket, Robert Pitt, provides his tech tips, product information, and industry news to keep you informed. We hope that our readers will enjoy these timely updates on exciting aftermarket topics.

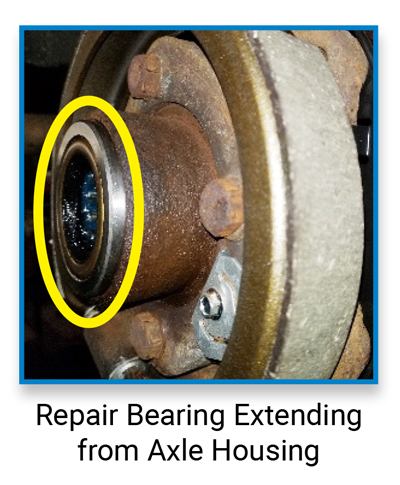

BCA Axle Shaft Repair Bearings (NBRP Part Numbers) can be used to replace the OE bearing and seal without requiring replacement of the worn axle shaft. Axle Shaft Repair Bearings feature a unitized design incorporating the bearing and seal into a single component. The design of repair bearings shifts the position of the bearing and seal along the axle shaft, allowing for unworn sections of the axle shaft to be the new points of contact.

Founded in 1918 and headquartered in Osaka, Japan, NTN is a leading manufacturer of a comprehensive range of bearings, constant velocity joints, wheel hub assemblies, and other precision industrial and automotive components. As the world’s third largest bearing manufacturer, we have over 68 plants worldwide and 100 years of premium quality to our name.

Take a look at this Tech Tip on Axle Shaft Repair. When you encounter a worn axle shaft, BCA can provide you with a replacement bearing that takes the original OE bearing which is actually two components and replaces it with one unitized unit. With this bearing you will not have to replace the entire axle shaft!

Howto makebearings

Bearing balls go through a very specific and thorough manufacturing process to create a ball that is perfectly round and smooth, minimizing friction within the bearing. The balls start out as a wire or rod slug that contains the necessary material required to form the finished ball. This wire goes through a process called “cold heading,” named for the lack of heat and original purpose of putting heads on nails, which is still used today. In this process, the wire ends are smashed towards each other, forming a ball with a small ring around it, called a “flash".

The rings are then placed in a heat treating furnace for hardening, and heated to around 1550 degrees F (840 C) for any time frame ranging from 20 minutes to several hours, depending on the size of the parts. They are then cooled in oil and tempered in a second oven at around 300 degrees F (148 C). This process makes the raceways both hard and durable.

Ball cages are a part of the bearing that can be made of a variety of different materials. For steel or metal cages, the outline of the cage is stamped out of a thin sheet of metal, and then placed into a mold-like structure called a “die,” which bends the cage into its proper shape. The cage can then be removed and is ready for assembly. For plastic cages, a process known as “injection molding” is used, in which melted plastic is injected into the mold and left to harden.

Whyare ball bearingshard to make

The OE wheel bearing design for these applications are engineered with separate bearing and seal components. Over time, the OE-designed wheel bearing and seal can wear grooves into the axle shaft at the points of contact. This leads to pitting on the axle shaft which can cause noisy operation and bearing failure, and can also cause differential fluid to leak onto the backing plate and brakes.

Ball bearings comprise a row or multiple rows of balls, which are held in a cage to keep them in place, between an inner and outer ring called raceways. There are often added features, such as seals to protect lubricants or screws to hold the bearing in place, however this article will just review the main parts of a basic bearing: the raceways, balls, and the cage.

Merry Christmas MROSupply Customers! All orders placed on the 24th and 25th of December 2024 will be processed promptly on the 26th of December.

The inner and outer raceways undergo a very similar manufacturing process. They begin as steel tubing, which is cut to the basic shape of the raceway by automatic machines, leaving a small amount of extra material to account for warping during the heating process. The outer rings are stamped with the bearing number and manufacturer information.

Generally, this type of wear necessitates the replacement of the axle shafts when replacing the bearing and seal. Failure to do so can result in premature failure of the new bearing and seal, which can cause additional damage to the axle, and even damage the differential due to fluid loss.

NTN is your trusted partner which it comes to innovation. You can rely on our R&D centres, our passion, our ability to listen and the expertise of our teams.

8613869596835

8613869596835