Angular Contact Ball Bearings - double row angular contact bearing

CS224n

Which of the two bearings is used as the fixed bearing is determined by considering the balance of the machine structure and bearing service life.

NTN Deep Groove Ball Bearing, Tight Fit Round Bore, Series: CS2, 25.4 mm Bore Dia, 52 mm Outside Dia, 1 Rows, 15 mm Width, Double Sealed Closure, 14000 N, Hardened Steel Bearing, Nitrile Rubber Seal, Pressed Steel Cage, -40 to 120 deg C, Uncoated

CS224W

A radial load and an axial load are applied to the fixed side bearing in order to fix the shaft and housing in the axial direction. For this reason, you should select a type of bearing that can support both the radial and axial loads and that is appropriate to the magnitude of these loads.

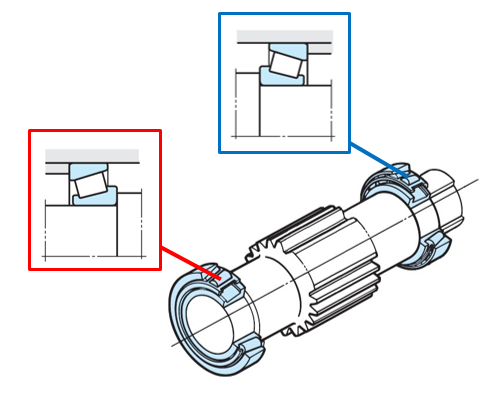

When the preload is applied to enhance rigidity to the shaft, there is no distinction between the fixed side and free side bearings. (Preload will be introduced in detail in Part 3 and later.) In this case, two angular contact ball bearings or tapered roller bearings are mounted with a back-to-back or face-to-face arrangement. (See Figure 10.)

CS234

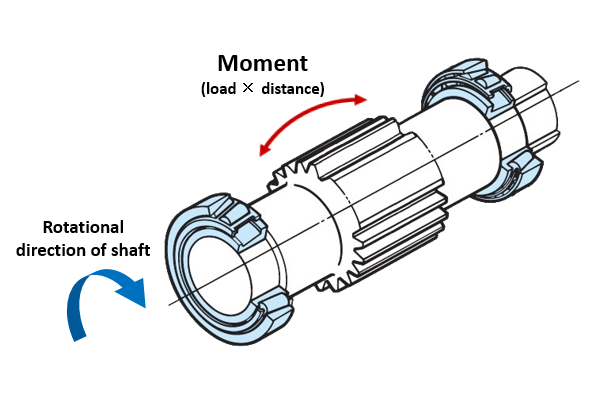

Table 5 shows a comparison of face-to-face and back-to-back bearing arrangement. When deciding between face-to-face or back-to-back bearing arrangement, it is necessary to take the "moment" into account.The "moment" is obtained by multiplying the magnitude of applied load and the distance to the point where the load is applied, and either face-to-face or back-to-back bearing arrangement is selected according to this "magnitude of moment."

When a machine is operated and the bearings rotate, heat will be generated inside the bearings. This heat is transferred to surrounding components, causing the shaft and the housing to expand (see Figure 1).

Cs224r

It is also possible for separate fixed side bearings to support a radial load and an axial load, respectively.As shown in Figure 4, there is also an arrangement in which a deep groove ball bearing supports the axial load, and a cylindrical roller bearing supports only the radial load, by providing a clearance between the outside diameter of the deep groove ball bearing and the bore diameter of the housing.

Deep groove ball bearings are very widely used. A deep groove is formed on each inner and outer ring of the bearing enabling them to sustain radial and axial loads in either direction as well as well as the complex loads which result from the combination of these forces. Deep groove ball bearings are suitable for high speed applications.

CS230

A large misalignment may occur between the inner and outer rings of the bearing due to load-induced shaft bending or mounting errors between the fixed side and free side bearings. If there is a large misalignment, an abnormal load will be put on the bearing, which can cause damage.

As indicated in Table 5, select face-to-face bearing arrangement when the moment is small, and back-to-back bearing arrangement when the moment is large.

Small machines that support small loads with short shafts are less affected by shaft expansion/contraction, so two bearings may be arranged without distinction between the fixed and free sides (see Figure 9).

While we are on the subject, do you all know what "arrangement" means in this context? "Arrangement" means what kind of bearings, and how many of them, to put in place relative to the shaft.In a standard machine, normally combining two (or more) bearings on a single shaft will provide additional load.In Part 2, we will show you some of the representative examples of combining two bearings on a single shaft.

We explained how to decide on the bearing arrangement in order to determine whether the bearing type you chose was appropriate.

CS229

Cs205l

For non-separable bearings (where the inner ring and outer ring cannot be separated), a clearance is provided between the outer diameter of the bearing and the inner diameter of the housing to prevent the thermal expansion and contraction of both the shaft and the bearing.

Bearings provide load by being inserted between the rotating and fixed parts of a machine.From among two bearings on a single shaft, one is designated as the fixed side bearing, and it fixes the shaft and housing in the axial direction. This is called "locating." The other bearing is designated as the free side bearing, and it allows the shaft to move freely in the axial direction, preventing thermal expansion and contraction of the shaft.

NTN CS205-100D1V14 Tight Fit Round Bore Deep Groove Ball Bearing, 25.4 mm Dia Bore, 52 mm OD, 1 Row, 15 mm W, 14000 N Load

As shown in Figure 5, the arrangement can also be such that the fixed side bearing is a large size of deep groove ball bearing that can support heavier radial load and axial load, while the free side bearing is a small size of deep groove ball bearing that supports only lighter radial load.

The free side bearing prevents thermal expansion and contraction of the shaft. In the case of a separable bearing (where the inner ring and outer ring can be separated), the expansion and contraction of the shaft is prevented between the rollers and the raceway surface.

In this column we will be using cross-section drawing like the above to convey the contents like those shown in the visual sketch.

8613869596835

8613869596835