Connecting Rod Bearings Set | Compatible with GM/ ... - gm rod bearing identification

At this point, you must have a qualified technician change out the worn components using a wheel bearing press to restore your vehicle to good working condition and eliminate distressing noises and poor ride quality.

RMSvibrationformula

In many cases, the diagnostic process will quickly pinpoint the front wheel bearings as the cause. Upon confirming the diagnosis, a technician will write up a work order that includes the total cost to replace your wheel bearings.

Vibration Analysis can be carried out using various functions such as FFT (Fast Fourier Transform), Time Waveform, 3D ODS (Object Deflection Shapes), FRF (Frequency Response Function), Bode Plot, Bump Test, Run Up Coast Down, Coherence, Orbits etc.

202137 — 9.5% = 0.095 in decimal form. Percent means 'per 100'. So, 9.5% means 9.5 per 100 or simply 9.5/100. If you divide 9.5 by 100, you'll get 0.095 (a decimal ...

Vibration analysiscourse

Our Expert Engineer will attend site to assess which equipment in your plant is suitable for monitoring by vibration analysis. A list of assets will be recommended for inclusion in the vibration programme, based on operation, running hours and criticality and from that a testing schedule will be established. Vibration data is then measured from the machines on a regular basis during our on-site inspection visits and machine condition assessed based on any increases in the parameters.

ATSvibration

We have an experienced team of Vibration Experts and operate various Vibration Analysis programmes in a wide range of industries, including Iron & Steel, Cement, Sugar, Power Plant, Petrochemicals & Refineries, Pharmaceuticals, Oil & Gas Production, Engineering Industries, Mining, Oil Rigs, Electrical Rewinding, Atomic Energy, Defence, Marine, etc.

Vibration Analysis is the most predominant technique for Detecting, Monitoring & Analyzing the vibration levels and frequencies of industrial machinery, and using that information it determines the "health" of the machine, and its components. Early detection of vibration is essential in order to avoid critical damage, expensive repair and possibly health and safety hazards.

After placing the hub in the press, it takes several minutes to change the wheel bearings. Your new bearings must also be pressed into the hub to seat their rear surface at the correct point.

At first, bad wheel bearings will start to squeak loudly while you drive. You will know it is time to replace the wheel bearing if the noise is constant, not just when you press the brakes.

Vibration analysiscourse UK

20241029 — Hearing noise that coincides with the rotation of your tires? A bad wheel bearing might be the culprit. Read on to know how to deal with the ...

Our priority is the total health of your plant’s assets. Our Vibration Analysis Services can be availed on an "as needed" call out basis, or can be tailored into a Predictive Maintenance Program (PdM) that will improve reliability, increase safety, optimize asset life, and enhance production and operating efficiencies.

Peruse our extensive collection of seal cross reference to narrow down your selection for the perfect fit.

Relubrication may mute the noise. That means you solved the problem, right? Unfortunately, this is not the case. Adding grease once your bearing has started to ...

Vibration analysis companiesNear me

Shaft alignment is a process to make two or more rotating shafts co-linear, or in the same straight line, both vertically and horizontally. Laser Shaft alignment

In-situ balancing is the process of balancing a rotor in its own bearings and support structure, in assembled conditions. Our specialised in-situ balancing

Search. My Account · Sign Out · All Categories. Ball Bearings. Search by Dimensions · Deep Groove Ball Bearings ...

Ridgid Geared Ratchet Tube Benders. by Ridge Tool Company ; Hazmat: N ; Jaw Width: 1 in ; ORS Nasco SKU Number: 632-35175 ; Overall Length [Nom]:. 21 in ; Prop 65 ...

We depute our expert Engineers for Emergency Call Basis requirements to detect the root cause of Vibration and accordingly plan a corrective action to avoid any type of losses due to unplanned shutdowns or breakdowns. Our engineers are located across various regions of India in order to offer the customer with our condition monitoring services 24/7

BBA Pumps has been manufacturing and supplying quick couplings for mobile pump systems for more than sixty years. All products with quick release couplings ...

Generally, Vibration Analysis techniques are used on a variety of assets such as pumps, electric motors, internal combustion engines, gearboxes, fans, electrical control panels, compressed air and hydraulic systems etc.

Remotevibration analysis

Enabled by our cloud-computing infrastructure, Our Remote Diagnostic Services allow any company with Internet access to implement a world-class PdM program, or to reduce the cost of an existing one.

A maintenance action report will be available to the client after each visits (Weekly, Bi-Weekly, Monthly, Bi-Monthly, Quarterly basis, Annual basis)

Browse Heavy Duty Needle Roller Bearings in the Roller Bearing Company Inc. catalog including RBC Heavy Duty Pitchlign Inner Ring,RBC Heavy Duty Pitchlign ...

In order to understand the big picture and repair your vehicle properly, technicians must check wear on a variety of components from tires and brakes to tie rods and control arms to find the source of the noise and vibrations.

Analysing the vibration patterns recorded enables us to diagnose what faults are occurring in the machine, i.e. bearing, coupling, imbalance, etc and the urgency required for its repair.

Your vehicle utilizes a wheel bearing at the hub to allow the tire and rim to smoothly rotate at both low and high speeds. As a rotating part, the wheel bearing's material slowly wears down during usage.

Let your local Meineke Car Care Center perform a diagnosis and we’ll let you know how we can repair or replace your wheel bearings to get your car back to a healthy state.

VibrationRMS vs peak

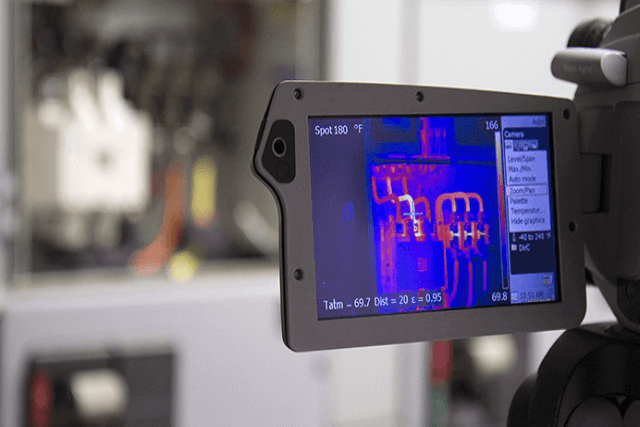

Infrared thermography is a technique of using a non-contact & non-destructive Infrared Scanning Camera to detect invisible Infrared thermal radiation of objects

Any time your vehicle is making unusually loud noises it’s safe to assume that something’s not right. Sometimes the culprit is your car’s wheel bearings. Wheel bearing press service, bearings replacement or other services may be required. Read below to learn about symptoms of problematic wheel bearings and replacement services.

Motion Amplificationvibration analysis

Technicians receive ample training to learn how to change wheel bearings correctly. Technicians use heavy-duty tools in the shop, including a large press, to pop the bearings out of the hub. On most vehicles, your technician must remove the tire, rotor and hub to access the bearing mounting point.

Odd Size Bearings · AMPEC · 1" bore 6205-2RS-1 Sealed Ball Bearing 6205-2RS-16 6205/25.4LLU · AMPEC · 1/2 6202-ZZ-1/2 Special Size Ball Bearing 1/2x35x11 Shielded ...

The MVA6850 expands the applications of Mityvac model MV6400 to include pressure bleeding hydraulic brake and clutch systems. The kit contains seven adapters ...

By giving you access to our expertise - and 24/7 access to your machine condition data. (Monthly, Quarterly basis, Annual basis)

Upon completing the service, the technician will take your vehicle for a test drive to check the noise levels and ride quality. If all goes well, you will then have your vehicle returned to you.

8613869596835

8613869596835