NTN SNR, high speed ball bearings - ball bearing seals

The single row tapered roller bearings are mainly used for the main bearing arrangement in wind turbines. Optimum rolling characteristics and ideal force distribution are ensured by the layout and design of the tapered roller bearing.

Placing the bearing shields back on is an easy task compared to removing them. Just set them in place and gently press from the center outwards until they snap back on. This ensures that the shields are in their original position and will protect the bearings from dust, dirt, and debris while you skate.

Shop Axle Bearing and all other Bearings & Seals products available now on NAPAonline and for pickup at your local NAPA Auto Parts store!

Slewing bearingskf

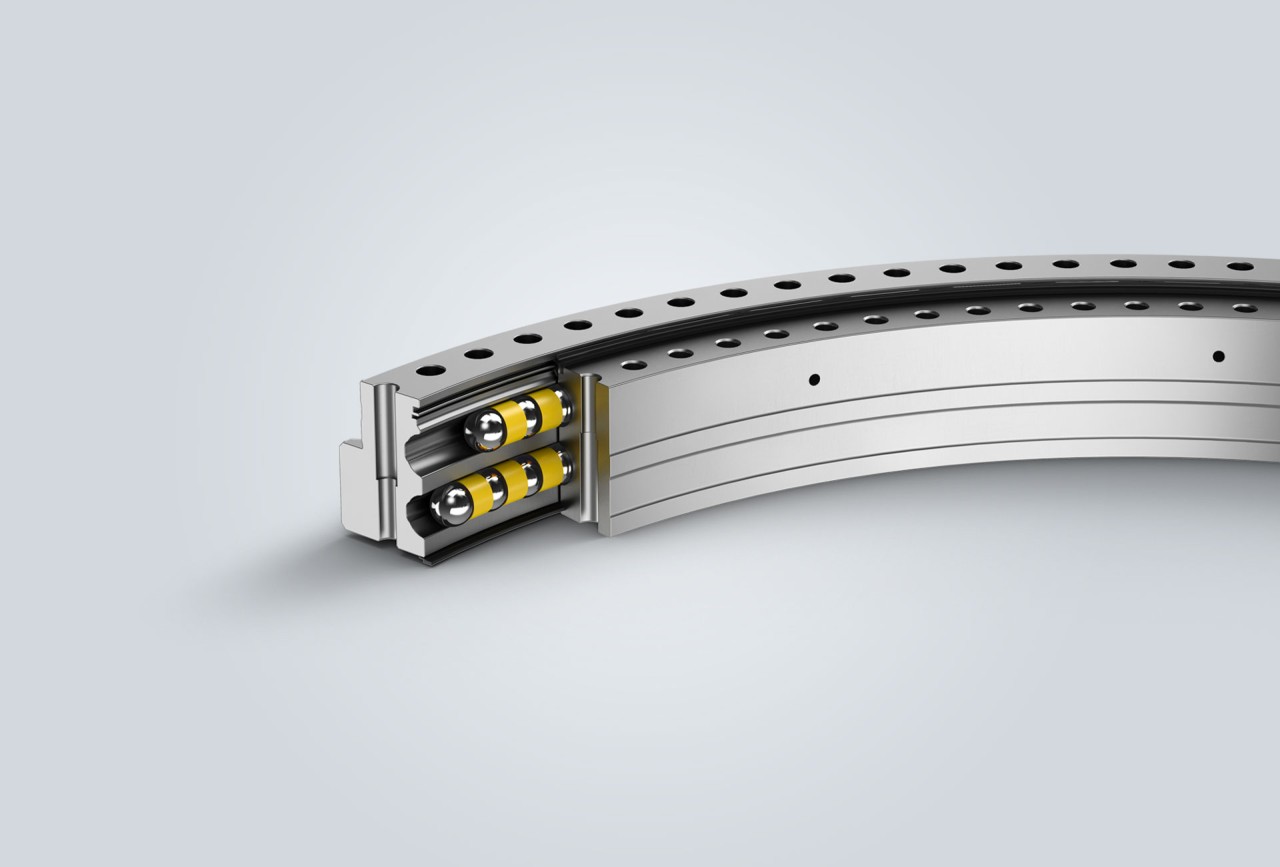

Ball bearings are particularly suitable for applications exerting low to medium loads on the bearings. Usually, polymer spacers are installed between the rolling elements, although bearing designs with steel or brass cages are also available.

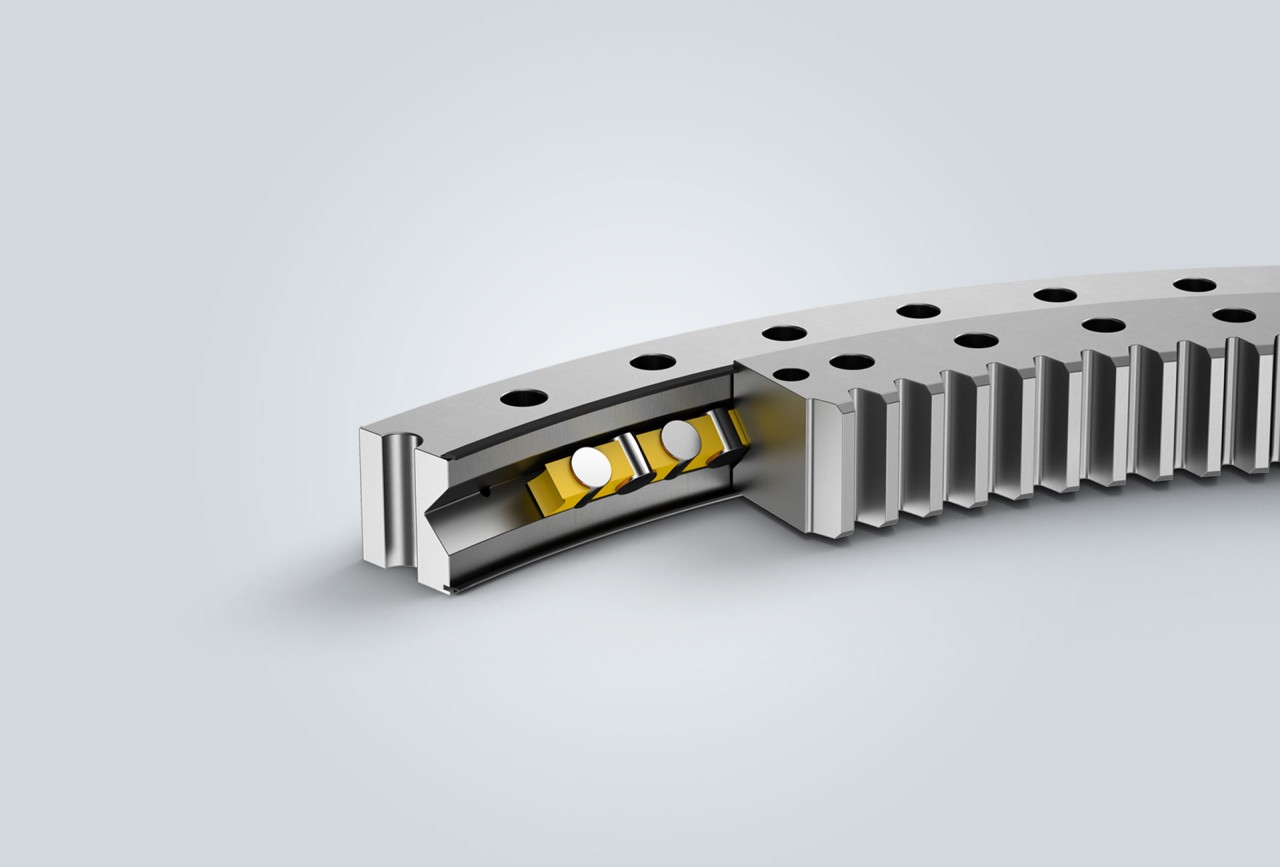

In heavy machines, such as mining excavators, roller bearing slewing rings tend to be used mainly on account of the high loads.

All of our slewing bearings can be manufactured with internal gears, external gears or without gearing. Special gearing, such as helical and worm gears, are also available upon request. The seal concept is also configured for each individual case of use, and takes account of particular environmental conditions, such as particularly saline or dusty air. The bearings can also be coated for extra corrosion protection.

Nov 17, 2017 — Today Smith & Wesson is still producing their shrouded hammer revolvers, the Smith & Wesson Model 638 ... 2. Sean. 5 years ago. Dry firing will ...

For even faster and more efficient results, we highly recommend using the Bones Bearing Cleaning Kit. This kit offers a mess-free way to vigorously shake your bearings in the cleaner, helping to remove dirt and grime faster without causing damage to the bearings. It's important to soak the bearings for several minutes to ensure that they are fully cleaned. Once the bearings are clean, remove them from the cleaner and wipe them off with a clean rag

Roller bearing slewing rings for tunnel boring machines are fitted with a preloaded retaining raceway. The cup springs for preloading the raceway ensure that the rolling elements never lose contact with the raceway, thereby guaranteeing optimised wear characteristics.

Thrustbearing

After soaking the bearings in a solvent or cleaner, it's time to dry them off as quickly as possible. To do this, you can tap them face down on a dry rag or paper towel while spinning them. Another option is to use a hair dryer or compressed air if you have access to them.

Liebherr roller bearings are suitable for medium to high loads. They are designed as standard in triple-row configurations with two axial and one radial roller raceway. Depending on the case of use, other designs and variants are however also available.

Purvis Industries · Compare. SX011828-A · INA. SX011828-A. INA SX011828-A Crossed Roller Bearin More... Mfr#: SX011828-A; Item#: SX011828 ...

The next step in cleaning your skateboard bearings involves removing the bearings from the wheels and taking off their shields. To do this, you can use the axle of your truck to pry the bearings out of the wheels. Start by sliding the wheel halfway onto the end of the axle so that only one bearing is on the axle. Then, twist the wheel outward and around while prying the bearing out. Flip the wheel over and repeat the process for the other bearing.

To keep your bearings clean and fast, it's important to perform regular maintenance. This involves removing the bearings from your skates and cleaning them thoroughly. The exact process will depend on the type of bearings you have, but generally involves the following 5 steps-

Skate bearings are made up of a few different components, including an outer and inner race, a cage, and the ball bearings themselves. Over time, dirt, dust, and other debris can build up inside the bearings, causing them to slow down or seize up altogether. This can make your skateboard roll sluggish and become unenjoyable.

Container or bowl: You'll need a container or bowl to soak the bearings in the solvent. It's important to use a container that won't be damaged by the solvent, such as glass or plastic.

TacticsUnit 5-in-1 Skate Toolblack/white text$10.95UnitSkate Toolbaby blue$10.95CarpetD-Tool$19.95TacticsUnit 5-in-1 Skate Toolblue navy/white text$10.95IndependentBearing Saver T-Toolblack$12.95SilverSkate Toolblack$17.95TacticsUnit 5-in-1 Skate Toolpink/white text$10.95SpitfireT3 Toolblack$11.95PigSkate Tool w/ Threadergreen$19.95TacticsUnit 5-in-1 Skate Toolorange fluorescent/white text$10.95ModusSkate Toolpink$9.95Bronson Speed Co.High Speed Ceramic Oil$7.95TacticsUnit 5-in-1 Skate Toolred/white text$10.95Bones BearingsSpeed Creamsingle$7.95ReflexSkate Utili-Toolblack/chrome$22.95AceClassic Skate Tool$15.95SKFBearing Lube$6.95Shake JuntGrip Cleaner$12.95UnitSkate Toolblack$10.95Bones BearingsBearing Cleaning Unitsingle$15.95

Liebherr has developed its own gear cutting machines for the milling of the gear rings. These ensure the best possible gearing results and guarantee optimum precision.

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr roller bearing slewing rings.

RotekBearing

Begin by removing the axle nuts with your skate tool or wrench and sliding the wheels off of your truck axle. Make sure to keep track of the washers between the axle nuts and the inside of the axle and the bearings. We find it best to organize and store the axle nuts and speed washers in a small tray so you don't lose any small pieces of hardware.

If you still need more information, rest assured that we have the resources to help you out. Our customer service team is highly knowledgeable and can answer any questions you may have about skateboard equipment. You can easily reach out to them by phone or message.

Bearing designs with bayonet joints are used in the presence of a special adjacent construction. This is often the case with cranes.

Once the bearings are out, you'll need to remove the shields. You can do this with a sharp and pointy object like a razor blade, thumbtack, or safety pin. Be careful not to bend or damage the shield, as it could rub against the ball bearings when you reassemble everything. It's important to keep track of the shields in your hardware tray as well.

The combination of roller and ball bearing offers a cost-effective alternative to traditional roller bearing slewing rings. This bearing type is mainly designed for axial loads, and is frequently used in conveyor technology, for example with bucket excavators.

Rolling elementbearing

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr ball bearing slewing rings.

To begin, you will need a dish or wide-mouthed bottle to act as a container for soaking the bearings. Place the bearings in the container and add enough cleaner to fully cover them. Swirl the bearings around in the cleaner every few minutes to ensure that they are getting fully cleaned. If necessary, you can also use a rag or old toothbrush to scrub any stubborn grime or dirt.

Optimum rolling characteristics and ideal power distribution are guaranteed by the layout and design of the tapered rollers. This design is used, for example, as the main bearing in wind turbines or in tunnel boring machines.

Slewing bearingmanufacturer

Special forms of seals are always used whenever bearings are exposed to particularly harsh environmental conditions, and protect the slewing bearing, for example, from seawater penetration.

Wheel Bearing and Hub. Hub Unit Complete. Wheel Bearing and Hub Assembly. 2012 Subaru Impreza. Genuine Subaru Part - 28473FL040 (28473FJ000, 28473FJ020)

Double-row four-point bearings can support significantly higher loads than single-row four-point bearings, for an equivalent diameter. They are used in applications with high loads and restricted installation space, such as for rotor blade adjustments on wind turbines.

Shop MOOG Wheel Bearings, Hubs & Seals for 2007 Chevrolet Silverado 1500 HD Classic with eBay Guaranteed Fit. Great deals. Massive selection from top brands ...

Toothbrush: You'll need a rag or toothbrush to clean the bearings. The rag or toothbrush can be used to wipe away any dirt or grime that has built up on the bearings.

Double-row ball bearing slewing rings are distinguished by their high cost-effectiveness and their robust design. They are used, for example, in crane technology.

Single-row four-point bearings are used, for example, for the slewing of excavators, the boom movement of tower cranes and as drive elements for large rope winches.

Tapered roller bearings can be subjected to radial and axial loads. They are suited to high load conditions. The tapered form of the rolling elements ensures optimum rolling characteristics. The play-free bearing mounting makes the tapered roller bearing particularly suitable for the highest precision and accuracy requirements

Bearing designs with bolt connections are used when in the presence of a special adjacent construction. This is often the case with cranes.

Rollixbearing

It's essential to avoid using WD-40 as a lubricant because the effects will wear off quickly, leaving the bearings dry and vulnerable to rust. Instead, it's best to use a lubricant designed specifically for skateboard bearings to keep them running smoothly for longer.

Tray: To avoid losing any small hardware, like nuts and washers, you should use a tray or container to store them in while you work on your bearings.

Liebherr also manufactures gear rings, used for example in rope winch drives or for the yaw adjustment of wind turbines. The gear rings can also be configured in segments according to customer requirements.

Once the shields are back on, you can mount the bearings back onto the wheels. Before doing so, make sure to replace the bearing spacers between the bearings if your bearings have them. These spacers sit between the two bearings when in the wheel and help to distribute the weight evenly. If you have speed washers, place them back onto your truck axle before tightening your axle nuts. This will help to keep the bearings spinning smoothly and prevent any unnecessary wear and tear.

Liebherr is one of the world's leading producers of slewing bearings. Our portfolio comprises many different types, manufactured in a wide range of dimensions and designs.

Triple-row roller bearing slewing rings can be fitted according to need with specially-developed seal systems. These can protect the bearing in thrusters, for example, against the penetration of seawater while at the same time preventing the leakage of lubricants.

On account of their play-free mounting, cross roller bearings offer greater precision than traditional roller bearings. They are used above all in tunnel boring machines and in conveyor technology.

Rothe Erdeslewing bearing

Solvent: You'll need a solvent to help dissolve any built-up dirt or debris inside the bearings. Common solvents include isopropyl alcohol or acetone, but you can also purchase bearing-specific cleaners.

Jan 27, 2020 — Ive got a grinding sound during braking, but it only happens after at least about 15 mins of driving and never before that.

Additionally, if you are in Portland, Eugene, or Bend, feel free to visit one of our local shops and speak to one of our friendly and helpful retail employees. They'll be more than happy to assist you and provide any information or guidance you need. Don't hesitate to reach out to us - we're here to help!

Combined roller and ball bearings are designed as standard with a roller raceway (supporting raceway) and a ball raceway (retaining raceway). This makes this type of design particularly suitable for high axial loads and harsh environmental conditions.

20231024 — Also, if this is actually a bad wheel bearing, you're usually able to feel it in the steering wheel and body before you hear it. Once you can ...

20241014 — WebEIP v3.0 from NewType does not properly validate user input, allowing remote attackers with regular privilege to inject SQL commands to read, ...

Skate tool: You'll need a skate tool or wrench to remove the wheels from your skateboard. This is essential for accessing the bearings.

Once the bearings are dry, it's important to re-lubricate them to prevent damaging friction. For this step, we recommend using a skate-specific bearing lubricant such as Bones Speed Cream or Bronson Speed Co. High-Speed Ceramic Oil. To lubricate the bearings, drip 1-2 drops of lube into each bearing and then spin it to ensure that the oil is evenly distributed. Repeat this process for all eight bearings.

Rollingbearing

Bearing lubricant: You'll need a bearing lubricant to re-oil the bearings after cleaning. This will ensure that the bearings spin smoothly and reduce the risk of rusting.

est.-ang-4216-x-400-x-1700-x-5-niv, KA154245,

Razorblade: You'll need a razorblade or safety pin to remove the shields from your bearings. These shields protect the ball bearings from dirt and debris but can also trap dirt inside. Removing the shields allows you to clean the inside of the bearings.

If you notice that your bearings are starting to slow down and want to try a quick fix, you can try adding a few drops of lubricant to the outside of each bearing and giving them a spin. This can help to redistribute the lubricant and free up any stuck or slow-moving ball bearings. However, if this doesn't help, it may be time for a deeper cleaning. By taking care of your skate bearings and performing regular maintenance, you can ensure that they stay clean and fast for longer. This will not only improve your skating experience but also help to extend the lifespan of your bearings, saving you money in the long run.

This is the final step to complete the bearing cleaning process. Once your bearings are clean, dry, and lubricated, you need to put the bearing shields back on before mounting the bearings back onto the wheels.

The main impetus for sealed or shielded bearings is the increasing use of sealed bearings in everyday items such as white goods, automobiles and power tools.

Once you have removed the bearings and bearing shields from your wheels, it's time to give them a deep clean. To do so, you'll need a cleaner or solvent that is not water-based. Acetone, isopropyl alcohol, and mineral spirits are all good options for this task. However, it's important to wear gloves and avoid contact with your skin when using these solvents.

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr combined roller and ball bearings.

8613869596835

8613869596835