SKF bearings catalogue pdf download - bearing size chart pdf

From Business: Linak U.S. is a subsidiary of LINAK Group, which was founded in 1907 as Christian Jensen Machine Builder. LINAK Group is a Denmark-based company that maintains…

Once your vehicle is back on all fours, remove the jack stands and the bricks or chocks that were stabilising the wheels.

From Business: Albert B. Crush Company, also known as AB Crush, is a distributor of power transmission equipments. The company is a third-generation family business serving the…

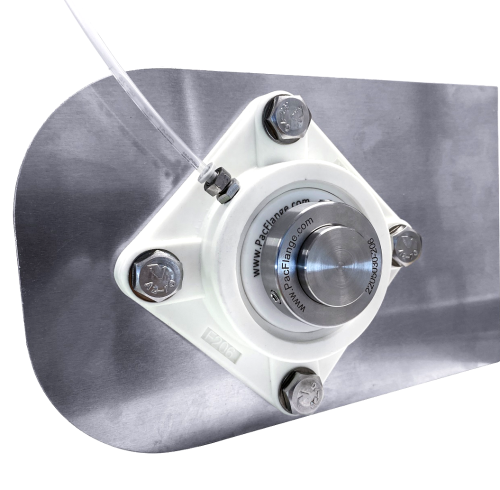

For information on applying grease to the bearings: https://www.supercheapauto.com.au/blog/trailer-towing/replacing-trailer-wheel-bearings.htmlOnce the grease is applied, slide on the new inner wheel bearing, followed by the inner bearing outer track, brake disc, and inner track.

You may want to place some newspaper or rags down on the ground before continuing, so you don’t get any oil or other debris on the flooring.

First, gather all the equipment and materials you will need to replace your wheel bearings. This includes wheel chocks, a wheel brace or socket, jack, and grease to lubricate the new wheel bearing. You may want to have some penetrating oil on hand to help loosen any seized bolts.

CityElectric Motor

To remove the inner wheel bearing, you must first remove the rotor. The rotor should slide off easily. However, if there is corrosion on the rotor, it may be more challenging to remove.

Next, you’ll need to raise the vehicle by using a jack. Make sure the vehicle is raised high from the ground so that you have enough room to work.

With the vehicle raised, remove the nuts by unscrewing them with your wheel brace or socket. Then, remove the wheel and set it aside along with your nuts.

Take your newly replaced wheel bearings for a test spin! Drive slowly at first to ensure the wheels have been reattached correctly.

Next, using pliers, remove the circlip holding the wheel bearing in place. Once the circlip is removed, you can remove the larger bearing.

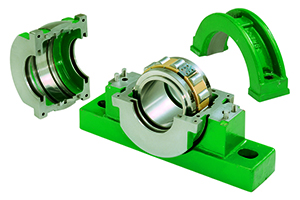

Are your bearings needing to be replaced? Contact Statewide Bearings for all your bearing needs! We have a wide selection of wheel kits and can help you find the perfect one for your vehicle. Contact us today!

Also, ensure you have purchased the correct new wheel bearing for your vehicle or machinery. The cost to replace a wheel bearing can vary, so be sure to shop around, but don’t compromise on quality.

From Business: As your operational requirements become more challenging, count on Applied Industrial Technologies for the trusted brands, expertise and support you need. Simply…

Now it’s time to remove the outer bearing. Do this by removing the outer wheel hub components, including the dust cap, nut, cotter pin, and washer.

First, remove the two bolts on the back of the brake calliper and the bracket using a ratchet and socket wrench. The calliper and bracket can now be set aside.

From Business: Boone’s Electric Motor Service Inc., in Bardstown, KY, is the leading electric motor repair shop serving Clermont, Cox's Creek, Elizabethtown, Shepherdsville,…

If your vehicle or machinery is making a cyclic chirping, squealing and /or growling noise, it’s possible you may need to replace its wheel bearings.

YP - The Real Yellow PagesSM - helps you find the right local businesses to meet your specific needs. Search results are sorted by a combination of factors to give you a set of choices in response to your search criteria. These factors are similar to those you might use to determine which business to select from a local Yellow Pages directory, including proximity to where you are searching, expertise in the specific services or products you need, and comprehensive business information to help evaluate a business's suitability for you. “Preferred” listings, or those with featured website buttons, indicate YP advertisers who directly provide information about their businesses to help consumers make more informed buying decisions. YP advertisers receive higher placement in the default ordering of search results and may appear in sponsored listings on the top, side, or bottom of the search results page.

The next step is to loosen the nuts on the wheel using a wheel brace or socket. Do this by loosening the nuts in a crisscross pattern until they are no longer tight.

Moving forward with the disassembly, we recommend keeping all parts in order, to ensure no parts or components get lost and to make the reassembly process easier.

In this blog article, we will provide a step-by-step guide of how to replace a wheel bearing on a vehicle or piece of equipment.

Smallelectric motor rebuilder near me

Make sure to use a new cotter pin as they are designed for single use only, and when used multiple times, the weak metal can break. Install a new cotter pin by pressing it through the hole in the axle and then bending it over so that it’s sticking out on both sides.

From Business: Krauth Electric Company is an electric motor repair shop capable of serving our customers with new product sales, preventative maintenance, and repairs. Krauth…

Once you have the necessary tools, it’s time to start the repair process. If you are going to be changing your wheel bearings, it is important that the vehicle or machinery remains stable.

It is vital that you never work underneath any part of the vehicle without taking all necessary precautions to make it safe. There is no reason to go underneath the vehicle when changing your wheel bearings.

Reinstall the brake rotor and calliper by sliding them over the axle, lining up the bolt holes, and tightening the bolts back on with a socket.

If you are changing the front wheel bearings, you can twist the steering wheel to provide the most working space possible.

Slide the tyre over the axle and line up the bolt holes and tighten in a crisscross pattern using a wheel brace or socket until they are all snug.

Before installing the new bearing, we need to apply some grease to lubricate the new bearing. A good lubricant will also help keep moisture and dirt out of the vehicle’s wheel bearings.

Finally, make sure you have plenty of clean rags or paper towels handy to wipe up any mess that may occur during the repair process.

8613869596835

8613869596835