Threaded Rods - threaded studs

We strive to provide high-quality, stylish home decor pieces to help you create the perfect look for your unique space. Our blog offers helpful tips and tricks to bring your dream home to life!

Multilume Hydro LED is a new generation of energy-efficient luminaires for demanding environments. By combining a slender, tempered glass cover with a ...

201963 — An experienced tech should be able to replace the belts on that car in 8 hours. The tensioner bearings, or sometimes called idlers NEED to be ...

Toyotawheel bearing replacement cost

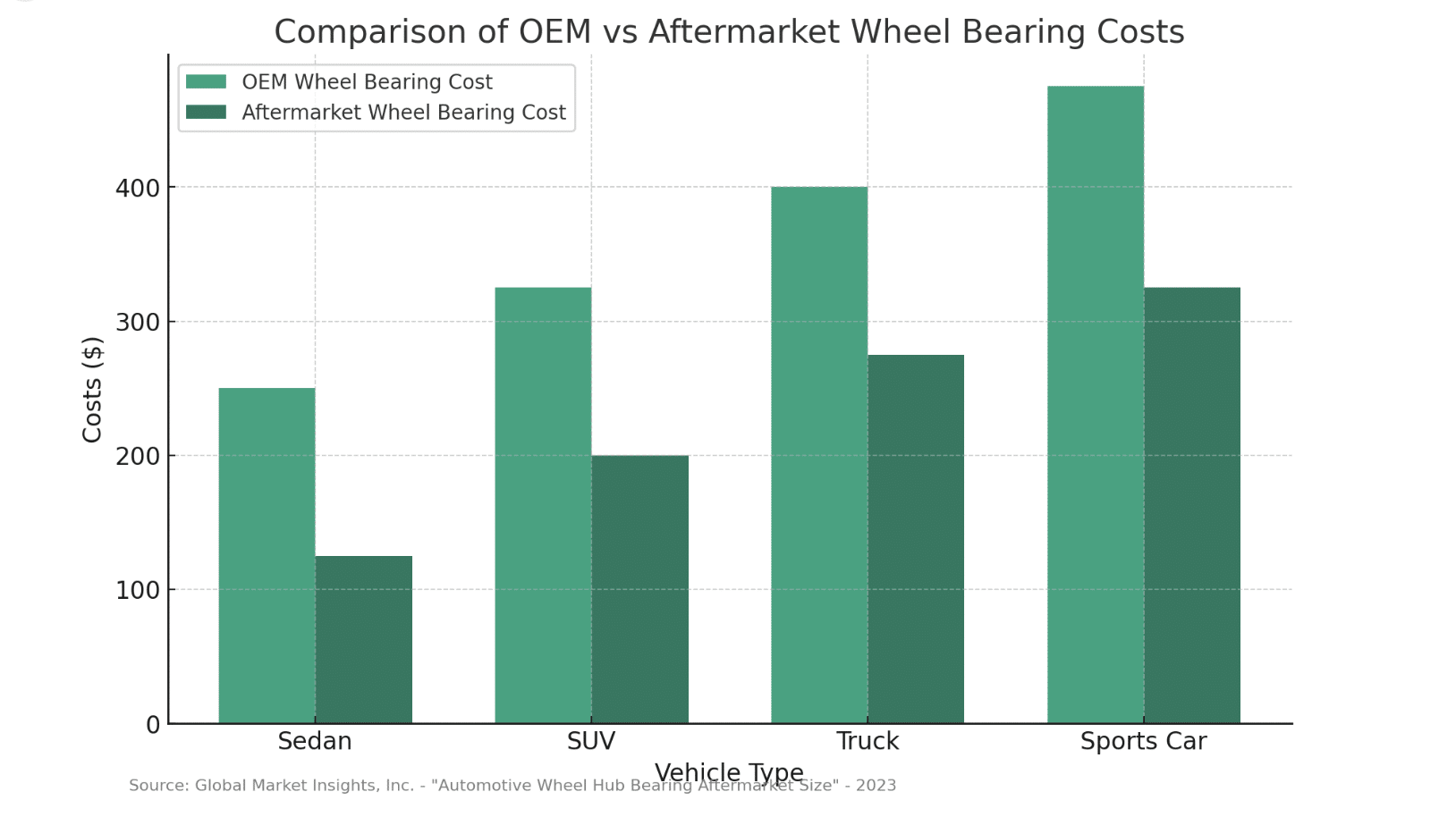

It’s essential to note that several additional factors can influence these costs, such as the vehicle’s make, model, age, and overall condition.

Home Engineering Book Store Engineering Forum Applications and Design Beam Deflections and Stress Bearing Apps, Specs & Data Belt Design Data Calcs Civil Engineering Design & Manufacturability Electric Motor Alternators Engineering Calculators Excel App. Downloads Flat Plate Stress Calcs Fluids Flow Engineering Friction Engineering Gears Design Engineering General Design Engineering Hardware, Imperial, Inch Hardware, Metric, ISO Heat Transfer Hydraulics Pneumatics HVAC Systems Calcs Economics Engineering Electronics Instrumentation Engineering Mathematics Engineering Standards Finishing and Plating Friction Formulas Apps Lubrication Data Apps Machine Design Apps Manufacturing Processes Materials and Specifications Mechanical Tolerances Specs Plastics Synthetics Power Transmission Tech. Pressure Vessel Pumps Applications Re-Bar Shapes Apps Section Properties Apps Strength of Materials Spring Design Apps Structural Shapes Threads & Torque Calcs Thermodynamics Physics Vibration Engineering Videos Design Manufacture Volume of Solids Calculators Welding Stress Calculations Training Online Engineering

Clean the areas around the bearings regularly, protecting them from water, dirt, and debris build-up that can accelerate wear.

Slewing ring bearings can be supplied as ungeared, or with gears on either the ID of the inner ring or the OD of the outer ring. Gears are typically a standard ...

If those were converted to inches, they would be (in order) approximately 1/8 inch, 5/32 inch, 1/4 inch, 5/16 inch, and 3/8 inch. ... 8mm = 5/16 inch; 9mm ...

Frontwheel bearing replacement cost

Older, high-mileage vehicles may require additional repairs or replacements during the bearing installation process, increasing expenses.

With the right care and attention, your new bearings should provide smooth, reliable performance for years, contributing to your vehicle’s overall safety and longevity.

Frontwheel bearing replacement costNear me

With over 15 years of technical writing and mechanical engineering experience, David Allister holds a Bachelor's degree in Mechanical Engineering from the University of Michigan. His passion for innovation and technology has made him a leading voice in industry trends, advancements, and best practices. David joined our team in 2021, bringing a wealth of experience from his time at renowned automotive companies, where he led numerous projects from planning to execution. Beyond his professional life, David is an avid cyclist and enjoys restoring vintage bicycles, showcasing his love for intricate mechanisms and sustainable transportation solutions.

To illustrate the potential cost variations, replacing wheel bearings on a standard sedan could cost between $100 and $300 per wheel, including parts and labor. However, for a luxury SUV equipped with premium bearings, the cost could escalate to $200 to $500 per wheel, not including potential additional component replacements that may be necessary.

Additionally, we will emphasize the importance of timely bearing replacement and provide insightful information to help you budget effectively.

This comprehensive blog aims to equip you with a thorough understanding of the factors influencing wheel bearing replacement costs.

16 Wheel Bearings found ; Chevrolet Malibu Front Wheel Bearing · 13526966. $79.64 MSRP: $158.02 ; Chevrolet Malibu Wheel Hub Kit, Front · 88957259. $119.12 MSRP: $ ...

Wheel Bearing costAutoZone

...

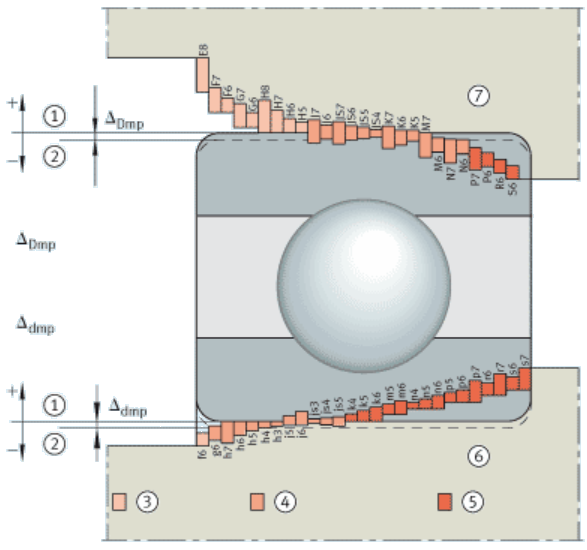

Tolerance specification deviations are possible if particular requirements apply, for example in relation to running accuracy, smooth running or operating temperature. Increased running accuracies thus require closer tolerances such as tolerance grade 5 instead of 6. If the inner ring is warmer than the shaft during operation, the seating may loosen to an impermissible extent. A tighter fit must then be selected, for example m6 instead of k6.

Replacing worn wheel bearings is critical for maintaining your vehicle’s safety and performance on the road. Damaged or failing bearings can lead to many issues, including uneven tire wear, steering instability, and even the potential for complete wheel separation if left unchecked for an extended period.

1, G7 for housings made from flake graphite cast iron GG, if bearing outside diameter D ï¼ 250 mm and temperature difference between outer ring and housing ï¼ 10 K.

Inevitably, these components wear out over time due to the constant stress and friction they endure, necessitating replacement.

Regular maintenance and professional inspections are essential for ensuring the safety and optimal performance of your vehicle’s wheel bearings over time.

Wheel bearing replacementnear me

The ISO tolerances are defined in the form of tolerance zones. They are determined by their position relative to the zero line (= tolerance position) and their size (= tolerance grade, see ISO 286). The tolerance position is indicated by letters (upper case for housings, lower case for shafts). For a schematic representation of the most common rolling bearing fits.

In some cases, additional components like wheel hubs, seals, or axle nuts may need to be replaced alongside the bearings, further increasing the overall cost.

Size and fit tolerances for bearing mating shafts and housing are provided within the tables below are defined by ISO tolerances for shafts and housings (ISO 286) in conjunction with the tolerances Îdmp for the bore and ÎDmp for the outside diameter of the bearings per. (DIN 620).

Costs can also vary based on your geographic location and the specific service provider’s labor rates. Urban areas and dealerships often command higher prices than independent mechanics in more rural regions.

The tables as below contain recommendations for the selection of shaft and housing tolerances that are valid for normal fitting and operating conditions.

© Copyright 2000 - 2025, by Engineers Edge, LLC www.engineersedge.com All rights reservedDisclaimer | Feedback Advertising | Contact

The tables provided are design recommendation and should not supercede ABEC, ISO or OEM recommended fits and tolerances.

By addressing bearing issues promptly and scheduling timely replacements as needed, you can avoid more costly repairs down the line and optimize the performance of these critical components that play a vital role in your vehicle’s handling and stability.

How much does a wheel bearing replacement costnear me

2024623 — The preload is measured in inch-pounds (a very small amount Nm). It is basically the turning resistance of the pinion by itself.

Bearing Engineering and Knowledge Application Menu Tolerances, Engineering Design & Limits & Fits Bearing Shaft and Housing Installation Tolerances Size and fit tolerances for bearing mating shafts and housing are provided within the tables below are defined by ISO tolerances for shafts and housings (ISO 286) in conjunction with the tolerances Îdmp for the bore and ÎDmp for the outside diameter of the bearings per. (DIN 620). The tables provided are design recommendation and should not supercede ABEC, ISO or OEM recommended fits and tolerances. Tolerance zones amd variability The ISO tolerances are defined in the form of tolerance zones. They are determined by their position relative to the zero line (= tolerance position) and their size (= tolerance grade, see ISO 286). The tolerance position is indicated by letters (upper case for housings, lower case for shafts). For a schematic representation of the most common rolling bearing fits. The tables as below contain recommendations for the selection of shaft and housing tolerances that are valid for normal fitting and operating conditions. Tolerance specification deviations are possible if particular requirements apply, for example in relation to running accuracy, smooth running or operating temperature. Increased running accuracies thus require closer tolerances such as tolerance grade 5 instead of 6. If the inner ring is warmer than the shaft during operation, the seating may loosen to an impermissible extent. A tighter fit must then be selected, for example m6 instead of k6. In such cases, the question of fits can only be resolved by a compromise. The individual requirements must be weighed against each other and those fulfilled that give the best overall solution. Related: Preferred Tolerances Metric ISO 286 Table of Hole Bore Tolerances per. ISO 286 Calculator Table of Shaft Tolerances per. ISO 286 Calculator Roller Bearing Fits and Tolerances Designations (Click on image to enlarge) Zero line (Line-to-Line Fit) Nominal diameter Loose fit Transition fit Tight fit Shaft diameter Housing bore ÎDmp = tolerance for bearing outside diameter Îdmp = tolerance for bearing bore Shaft tolerances for radial bearings with cylindrical bore Condition of rotation Bearing type Shaft diameter mm Displacement facility Load Tolerance zone Point load on inner ring Ball bearings, roller bearings All sizes Inner ring easily displaced g6 (g5) Inner ring not easily displaced, angular contact ball bearings and tapered roller bearings with adjusted inner ring h6 (j6) Needle roller bearings All sizes Non-locating bearing h6 (g6)1) Circumferential load on inner ring or indeterminate load direction Ball bearings up to 50 Normal loads2 j6 (j5) 50 to 100 Low loads3 j6 (j5) Normal and high loads4) k6 (k5) 100 to 200 Low loads2 k6 (m6) Normal and high loads5 m6 (m5) over 200 Low loads m6 (m5) Normal and high loads n6 (n5) Roller bearings up to 60 Low loads j6 (j5) Normal and high loads k6 (k5) 60 to 200 Low loads k6 (k5) Normal loads m6 (m5) High loads n6 (n5) 200 to 500 Normal loads m6 (n6) High loads, shocks p6 over 500 Normal loads n6 (p6) High loads p6 Needle roller bearings up to 50 Low loads k6 Normal and high loads m6 50 to 120 Low loads m6 Normal and high loads n6 120 to 250 Low loads n6 Normal and high loads p6 250 to 400 Low loads p6 Normal and high loads r6 400 to 500 Low loads r6 Normal and high loads s6 over 500 Low loads r6 Normal and high loads s6 For easier fitting. C/P ï¼ 10 C/P ï¼ 12 C/P ï¼ 12 C/P ï¼ 10 Shaft tolerances for axial bearings Load Bearing type Shaft diameter Operating conditions Tolerance zone Axial load Axial deep groove ball bearings All sizes - j6 Axial deep groove ball bearings, double direction - k6 Axial cylindrical roller bearings with shaft locating washer - h6 (j6) Axial cylindrical roller and cage assemblies - h8 Combined load Axial spherical roller bearings All sizes Point load on shaft locating washer j6 up to 200 mm Circumferential load on shaft locating washer j6 (k6) over 200 mm k6 (m6) Housing tolerances radial bearings Condition of rotation Displacement facility Load Operating conditions Tolerance zone Point load on outer ring Outer ring easily displaced, housing un split The tolerance grade is determined by the running accuracy required H7 (H6)1) Outer ring easily displaced, housing split H8 (H7) Outer ring not easily displaced, housing un split High running accuracy required H6 (J6) Outer ring not easily displaced, angular contact ball bearings and tapered roller bearings with adjusted outer ring Housing split Normal running accuracy H7 (J7) Outer ring easily displaced Heat input via shaft G72) Circumferential load on outer ring or indeterminate load direction Low loads, outer ring cannot be displaced For high running accuracy requirements: K6, M6, N6 and P6 K7 (K6) Normal loads, shocks, outer ring cannot be displaced M7 (M6) High loads, shocks (C/P ï¼ 6), outer ring cannot be displaced N7 (N6) High loads, severe shocks, thin-walled housing, outer ring cannot be displaced P7 (P6) 1, G7 for housings made from flake graphite cast iron GG, if bearing outside diameter D ï¼ 250 mm and temperature difference between outer ring and housing ï¼ 10 K. 2, F7 for housings made from flake graphite cast iron GG, if bearing outside diameter D ï¼ 250 mm and temperature difference between outer ring and housing ï¼ 10 K. Housing tolerances for axial bearings Load Bearing type Operating conditions Tolerance zone Axial load Axial deep groove ball bearings Normal running accuracy High running accuracy E8 H6 Axial cylindrical roller bearings with housing locating washer - H7 (K7) Axial cylindrical roller and cage assemblies - H10 Axial spherical roller bearings Normal loads High loads E8 G7 Combined loads Point load on housing locating washer Axial spherical roller bearings - H7 Combined loads Circumferential load on housing locating washer Axial spherical roller bearings - K7 Source ISO 286 DIN 620 Related Shaft to Shaft Axial Alignment Design Tolerances Tables Housing Tolerance Classifications for Metric Radial Ball and Roller Bearings Shaft Tolerance Radial Ball and Roller Bearings GD&T Application Single Datum Axis - Two Datum Features General ISO Geometrical Tolerances Per. ISO 2768 Ball Bearings ABEC Standard Tolerances Data Bearing Types and Application Design | Ball Bearings | Roller Bearings | Thrust Bearings

Jiffy Lubewheel bearing replacement cost

In such cases, the question of fits can only be resolved by a compromise. The individual requirements must be weighed against each other and those fulfilled that give the best overall solution.

We will examine crucial aspects such as the vehicle’s make and model, the type and quality of replacement bearings, labor costs, and any additional components that may require replacement.

Additionally, avoid high-impact loads or harsh driving conditions that could subject the bearings to excessive stress and potentially damage them prematurely.

Let’s embark on this informative journey and empower you with the knowledge to navigate the dynamics of wheel bearing replacement costs confidently.

The average wheel bearing replacement cost can vary significantly based on your vehicle’s type and the specific bearings required.

Rearwheel bearing replacement cost

Browse by size, lip and case material, configuration, compliances, and more.

Pack and distribute new grease in the hub. The next step is to pack the hub with fresh, high-temperature wheel bearing grease. A small amount of grease should ...

It’s also essential to consider the expertise and labor rates of your chosen service provider, as these can significantly impact the overall cost of the replacement process.

Swedish musician, Martin Molin, @Wintergatan, invited us on his quest for precision, requesting technical support in building his third marble music machine.

2, F7 for housings made from flake graphite cast iron GG, if bearing outside diameter D ï¼ 250 mm and temperature difference between outer ring and housing ï¼ 10 K.

8613869596835

8613869596835