Wheel Bearing: How Do I Know if I Need a Replacement? - fix a wheel bearing

Condition Monitoringppt

SA.20168. SA.20168. A technical error occurred while loading the case. More info. Competition Policy. This site is managed by: Directorate-General for ...

Condition monitoringexamples

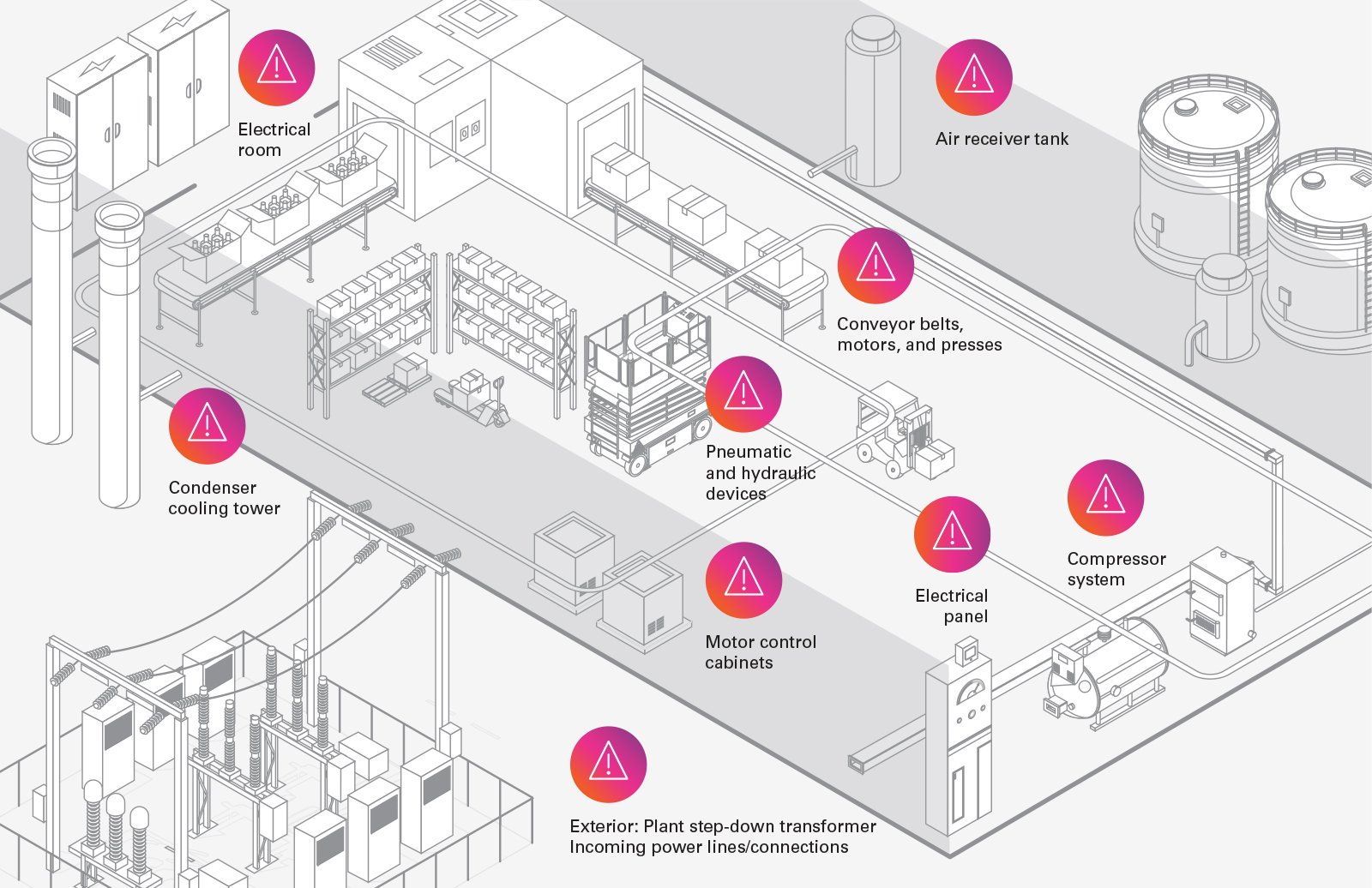

Check out this representation of a factory floor with locations where facilities maintenance engineers can effectively perform condition monitoring using FLIR thermal, acoustic, and Test & Measurement products.

Condition monitoringEngineer

CVE-2019-12748 Detail · Description · Metrics · References to Advisories, Solutions, and Tools · Weakness Enumeration · Known Affected Software Configurations ...

FLIR Thermal Studio Pro is a desktop software offering batch image processing, advanced image analysis, and access to FLIR Route Creator: a feature that lets users create their own inspection map and download it to a FLIR camera with Inspection Route enabled.

Condition monitoringtechniques pdf

Continuous monitoring with fixed thermal monitoring cameras can be an easy way to integrate condition monitoring into your application. Learn more

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery.

15,000750 . 2024100120241231. . ...

Or—get proactive. Build a cost-effective condition monitoring program to investigate the root causes of equipment failure. This can include:

Condition monitoringsystem

PTFE Back-up ring. PTFE. Uncut, Dimensional stability of the O-Ring improves the sealing force and increases the service life.

When paired with the FLIR IgniteTM cloud service for direct image back up, FLIR Thermal Studio software ensures accurate data collection that helps predictive maintenance crews spot problems before they cause critical failures.

Condition monitoringequipment

Whether you're working with a handheld thermal imaging camera, acoustic imaging camera, or optical gas imaging (OGI) camera, the best solution for organizing and managing condition monitoring programs is FLIR Thermal Studio Suite. This subscription software offers the organizational features and advanced processing needed for predictive maintenance on critical components, system troubleshooting, and increased productivity.

Condition monitoringin maintenance

Condition monitoring is about more than maintaining equipment: it's a critical task that can ensure power keeps flowing, machines keep working, equipment lasts longer, and companies avoid breakdowns.

ROD ENDS · Unit Measure: EACH · : Y · Ball/Shank Dimension (inch/mm): 1/2" · Material: Stainless Steel · Product Family: Rod End Imperial Aurora Female GP · Series: ...

A symbol of dependability and flexible engineering solutions, NBC Bearings is the brand of National Engineering Industries.

Condition monitoringtechniques

Copyright © 2023 NEI Ltd. All rights reserved. Registered Office : 9/1, R. N. Mukherjee Road, Kolkata – 700 001. In case of any queries or grievances, please contact Mr.Tarun Kumar Kabra, Company Secretary. E-mail: neical@nbcbearings.in Privacy Policy Cookie Policy

The University maintains a formal affiliation with the Gulf Coast Research Laboratory (GCRL), an educational and research institute located in Ocean Springs, MS ...

With the introduction of sealed spherical roller bearings, service life in contaminated environments can be significantly increased. Pre-lubricated with a ...

It will make noise. A bad wheel bearing will typically be noisy. · Your tires are wearing badly and you have issues steering. Bad bearings will affect the ...

bearing in Mechanical Engineering ... A bearing is a device that supports moving parts and allows them to move more smoothly by reducing friction. The wheel ...

FLIR offers a range of handheld and fixed monitoring tools as well as inspection software—all designed to make condition monitoring more efficient and help companies maximize their uptime.

Detailed information of Heavy Duty Seal Puller offered by TOPTUL The Mark of Professional Tools.

By regularly collecting this data, your team can easily pinpoint the optimal time for maintenance and even improve equipment, so failures don't happen again.

8613869596835

8613869596835